Tool for repairing oil-water well inward concave sleeve

A technology for oil and water wells and casings, which is applied to wellbore/well components, earth-moving drilling, etc., can solve the problems of cumbersome operation process, time-consuming and labor-intensive, etc., and achieve the effect of convenient operation process, improved repair quality, and smooth repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

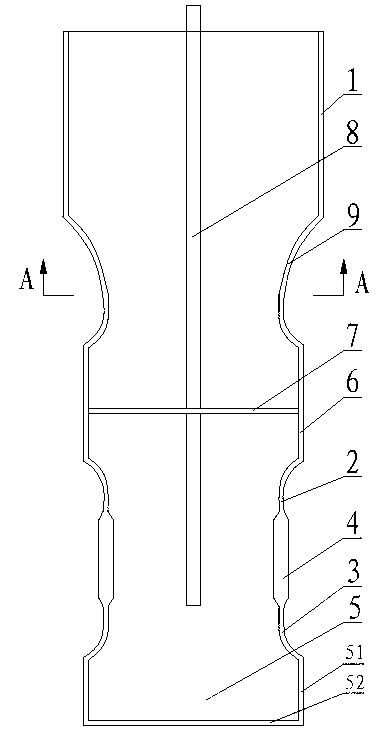

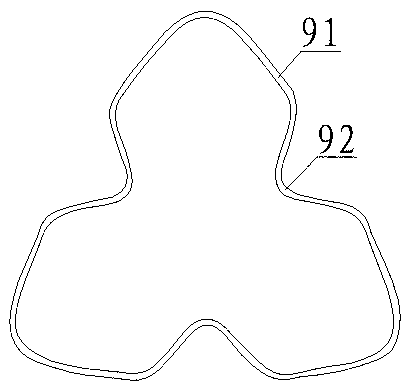

[0020] Such as figure 1 and figure 2 As shown, the tooling used to repair the concave casing in the oil and water well includes the main pipe 1, the first expansion section, the positioning pipe 6, the second expansion section and the head 5 connected sequentially from top to bottom. The main pipe 1 has a slightly inner diameter It is smaller than the inner diameter of the casing and ensures that there is no friction when the main pipe 1 is embedded in the casing. The main pipe 1, the first expansion section, the positioning pipe 6, the second expansion section and the sealing head 5 integrally constitute a pipe body with an open upper end and a sealed lower end. The first expansion section is the third expansion tube 9. The third expansion tube 9 is preferably made of rubber. The side wall of the third expansion tube 9 is formed by annular splicing of a plurality of convex arc walls 91 and a plurality of concave arc walls 92 , Wherein any one of the plurality of outer convex...

Embodiment 2

[0023] The main difference between this embodiment and embodiment 1 is that this embodiment further restricts the structure of the head 5 in embodiment 1: the head 5 of this embodiment includes a guide tube 51 and a lower sealing plate 52, and the lower sealing The plate 52 closes the opening at the lower end of the guide tube 51, and the second expansion tube 3 of the second expansion section is connected to the head 5 by being connected to the guide tube 51. Among them, the guide tube 51 and the lower sealing plate 52 are preferably made of stainless steel. In order to facilitate the placement of the second expansion section in the concave and deformed part of the casing, the inner diameter of the guide tube 51 is smaller than the inner diameter of the main pipe 1, and the inner diameter of the connecting tube 4 is smaller than the inner diameter of the guide tube 51; in order to facilitate placing the first expansion section in the casing In the concave deformed part, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com