Method and device for measuring pore volume change of porous medium

A technology of pore volume and porous media, applied in measuring devices, suspension and porous material analysis, permeability/surface area analysis, etc., can solve the problems of inconvenient reading, complicated operation, rapid deformation and destruction process, etc., and achieve remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for measuring the pore volume variation of porous media, the steps are as follows:

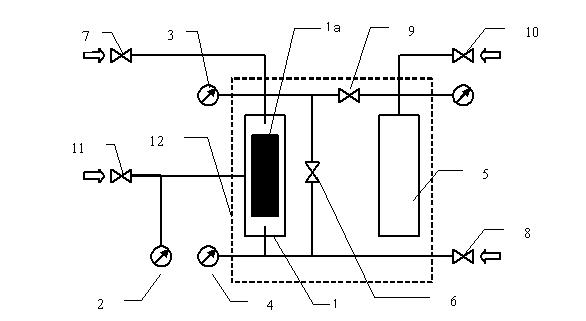

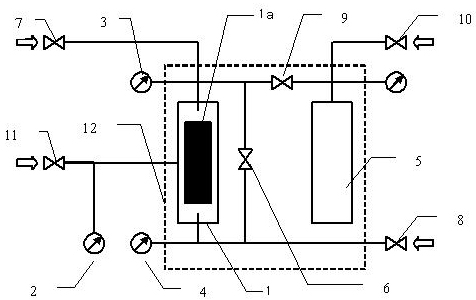

[0049] 1) According to figure 1 It can be seen that the test piece 1a is placed in the holder 1, the entire measuring device is placed in the constant temperature bath 12, the constant temperature bath 12 is turned on and the constant temperature is set and the temperature reading T is recorded. 0 (T 0 Slightly higher than room temperature, here is 20-60°C), which is the initial temperature. After the temperature stabilizes, fill the port of the confining pressure control valve 11 with oil to load the confining pressure stress, and record the reading Pc of the confining pressure gauge 2 0 (Pc 0 higher than the pore compressive stress, here is 1~70MPa), which is the initial confining compressive stress of the tested piece.

[0050] 2) Close the upstream control valve 7 and the pressure regulating and venting valve 10, open the communication valve 6, the downstream control val...

Embodiment 2

[0055] according to figure 1 It can be seen that a measuring device for the volume change of pores in porous media includes a holder 1, a confining pressure gauge 2, an upstream pressure gauge 3, a downstream pressure gauge 4, a pressure regulating controller 5, a communication valve 6, and an upstream control valve 7 , downstream control valve 8, pressure regulating control valve 9, vent valve 10, confining pressure control valve 11 and constant temperature bath 12.

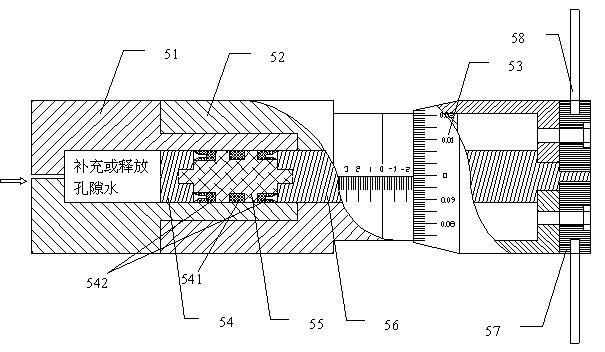

[0056] The test object 1a is placed in the holder 1, the confining pressure control valve 11 is connected to the confining pressure end of the holder 1, the confining pressure end of the holder 1 is connected to the confining pressure gauge 2, the upstream pressure gauge 3 and the downstream The pressure gauge 4 is respectively connected to the upstream and downstream of the holder 1, the communication valve 6 is connected to the upstream and downstream of the holder 1 for closing or disconnecting the upstream a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com