Bounce-free plug-in type vacuum arc-extinguishing chamber

A vacuum interrupter, plug-in technology, used in high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve problems such as wear on the outer peripheral surface, and achieve the effect of eliminating bounce and solving wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

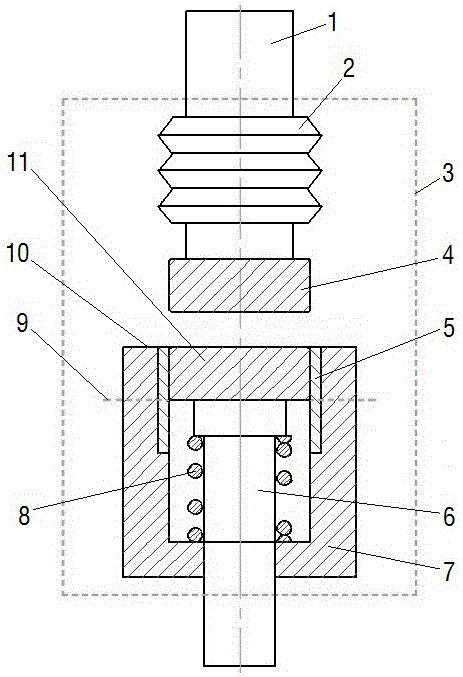

[0017] Examples of bounce-free plug-in vacuum interrupters figure 1 As shown, it includes a ceramic shell 3, and the ceramic shell 3 is provided with a moving contact 4 and a static contact assembly arranged up and down. The upper end of the moving contact 4 is sequentially connected to the bellows 2 and the upper The conductive rod 1 is also provided with a shielding case (not shown in the figure) in the ceramic shell 3 .

[0018] The static contact assembly includes a static contact 7, and the static contact 7 is provided with a contact portion for plugging and conducting electricity with the outer peripheral surface of the movable contact 4. In this embodiment, the contact portion is an elastic conductor, specifically a watch strap Finger 5. On the static contact 7, the buffer contact 11 that is used to connect with the movable contact 4 to conduct electricity is provided with a buffer contact 11 that is in contact with the end surface of the movable contact 4 through an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com