Earthquake-resistant economic caisson wharf and construction method thereof

An economical caisson wharf technology, which is applied in the earthquake-resistant economical caisson wharf and its construction field, can solve the problems of site occupation, environmental pollution, etc., and achieve the effects of reducing soil pressure, improving stability, and reducing project costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

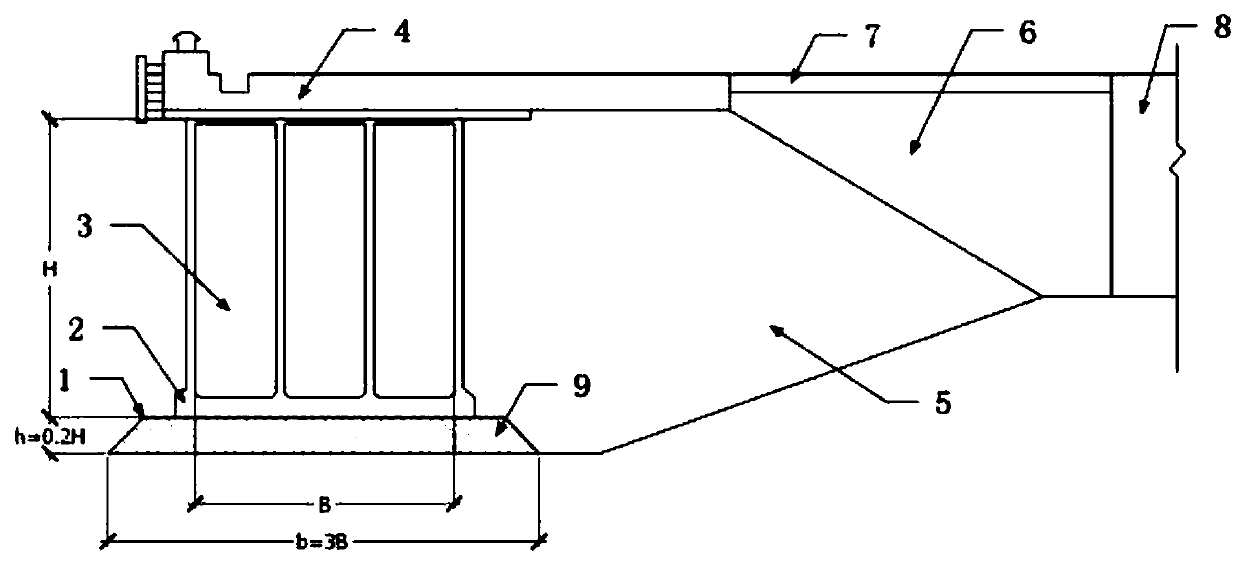

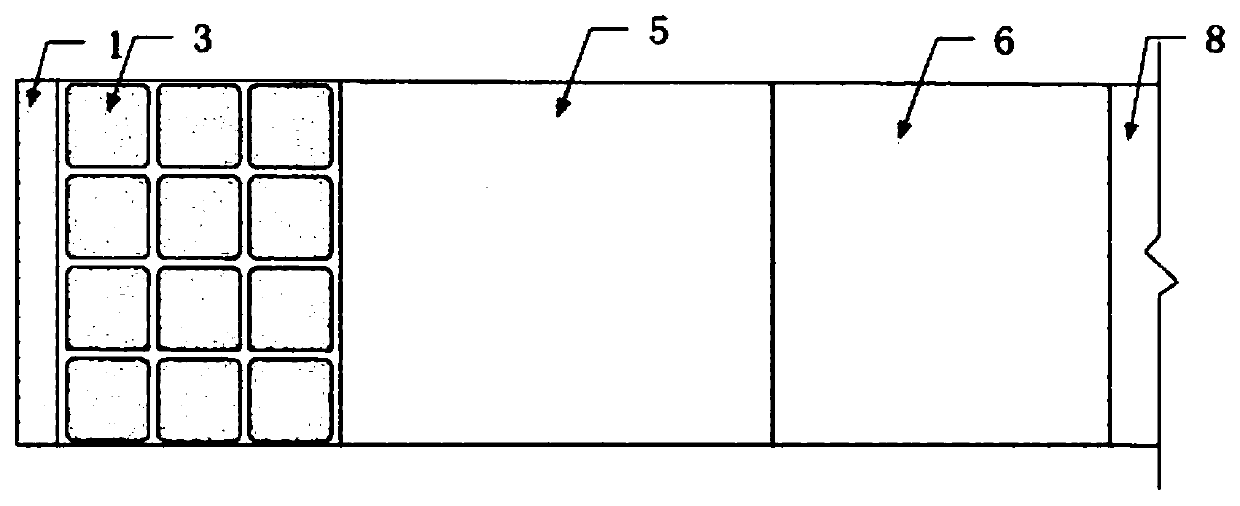

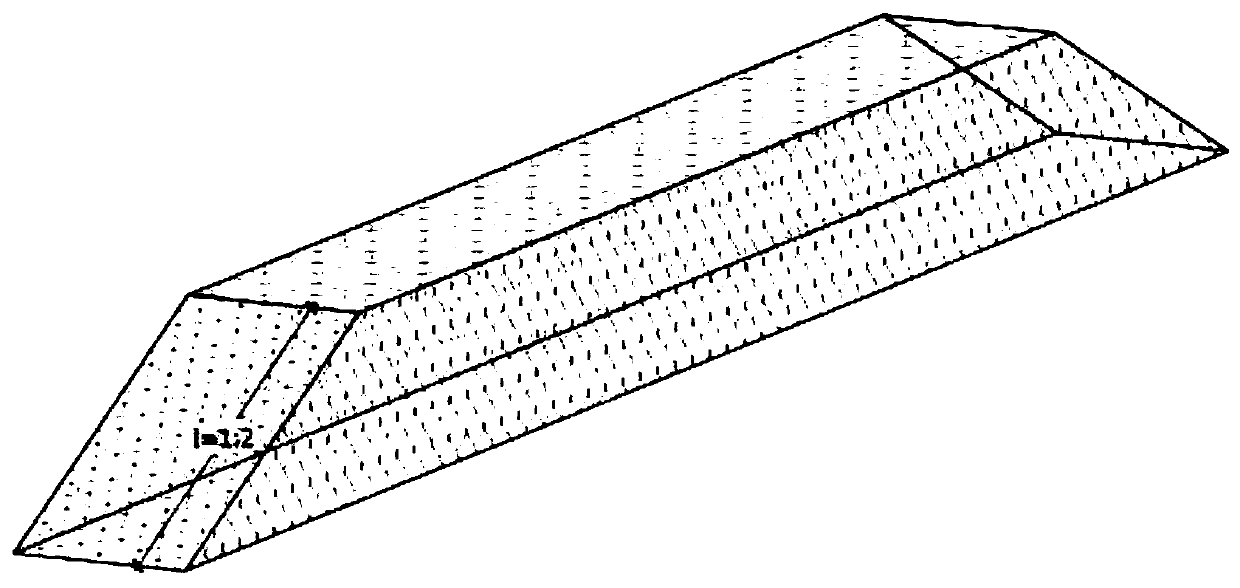

[0042] (1) Prefabricate the caisson main body 2, do a good job in the relevant formwork calculation and formwork reinforcement work, carry out layered pouring for the larger caisson main body 2, and prepare the corresponding construction plan;

[0043] (2) Excavate foundation trenches by means of grab boats, cutter suction boats, drag suction boats, etc.;

[0044] (3) Fixed forming lead wire cage 9, the steel slag that particle diameter is 30mm and length is 40mm, and the scrap tire fragment that width is 30mm mixes by mass ratio 1: 9, and fills hot-dip galvanized lead wire cage 9, forms lead wire cage 9 fixed hybrid structure;

[0045] (4) The excavated foundation trench shall be inspected by means of sea survey, and a layer of 10cm thick sand shall be laid flat after passing the inspection. On the foundation bed of the wharf, a seismic isolation foundation 1 is formed;

[0046] (5) After the installation of the seismic isolation foundation 1 is completed, semi-submerged ba...

Embodiment 2

[0053] (1) Prefabricate the caisson main body 2, do a good job in the relevant formwork calculation and formwork reinforcement work, carry out layered pouring for the larger caisson main body 2, and prepare the corresponding construction plan;

[0054] (2) The reef blasting ship is used to blast the reef, and then the grab ship is used to excavate the foundation trench;

[0055] (3) Fixedly form the lead wire cage 9, the steel slag with a particle diameter of 50 mm and the length of 100 mm, the waste tire fragments with a width of 50 mm are mixed in a mass ratio of 3:9, and the hot-dip galvanized lead wire cage 9 is filled to form the lead wire cage 9 fixed hybrid structure;

[0056] (4) Check the excavated foundation trench by spotting water, spread a layer of sand with a thickness of 12cm after the acceptance, and place the mixed structure fixed by the lead wire cage 9 section by section by hoisting after leveling On the foundation bed of the wharf, a seismic isolation foun...

Embodiment 3

[0064] (1) Prefabricate the caisson main body 2, do a good job in the relevant formwork calculation and formwork reinforcement work, carry out layered pouring for the larger caisson main body 2, and prepare the corresponding construction plan;

[0065] (2) Excavate foundation trenches by means of grab boats, cutter suction boats, drag suction boats, etc.;

[0066] (3) fixed forming lead wire cage 9, the steel slag that particle diameter is 40mm and length is 70mm, and the scrap tire fragment that width is 40mm mixes by mass ratio 3: 7, and fills hot-dip galvanized lead wire cage 9, forms lead wire cage 9 fixed hybrid structure;

[0067] (4) The excavated foundation trench is inspected by means of sea survey, and a layer of 11cm-thick sand is spread flat after passing the inspection. On the foundation bed of the wharf, a seismic isolation foundation 1 is formed;

[0068] (5) After the installation of the seismic isolation foundation 1 is completed, semi-submerged barges and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com