cutting device

A technology for cutting devices and components, which is applied to shearing devices, operating devices, accessories of shearing machines, etc., can solve problems such as the replacement of difficult-to-fix knives or pressing components, the time-consuming cleaning operations, and the impact of bar cutting accuracy. To achieve the effect of eliminating bounce and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

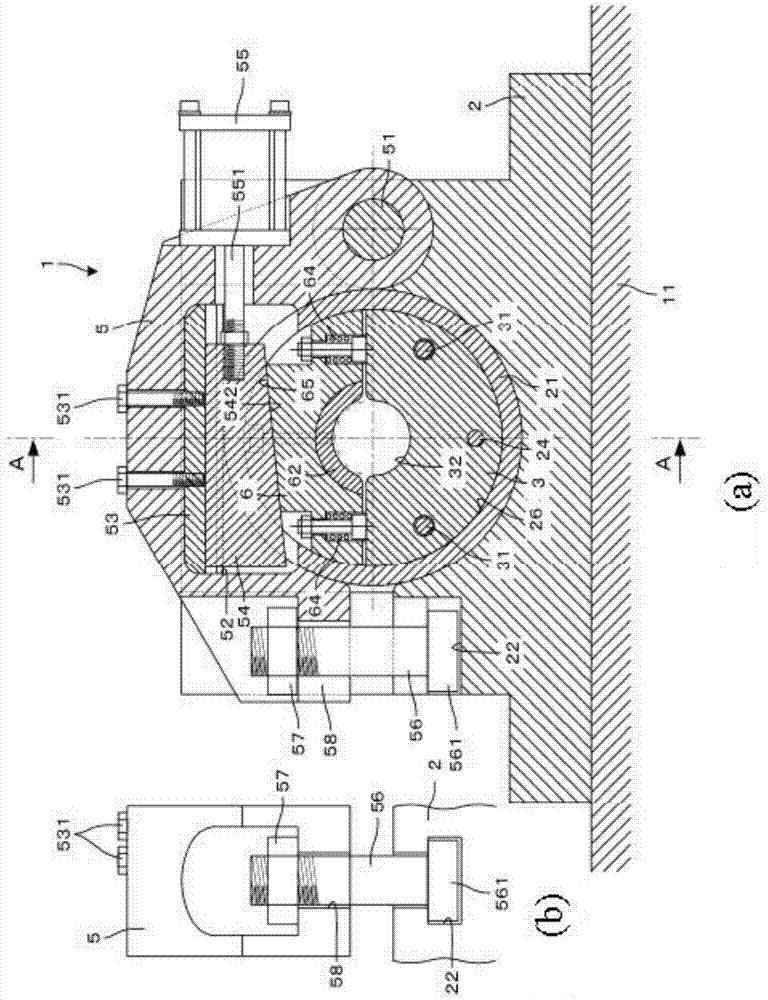

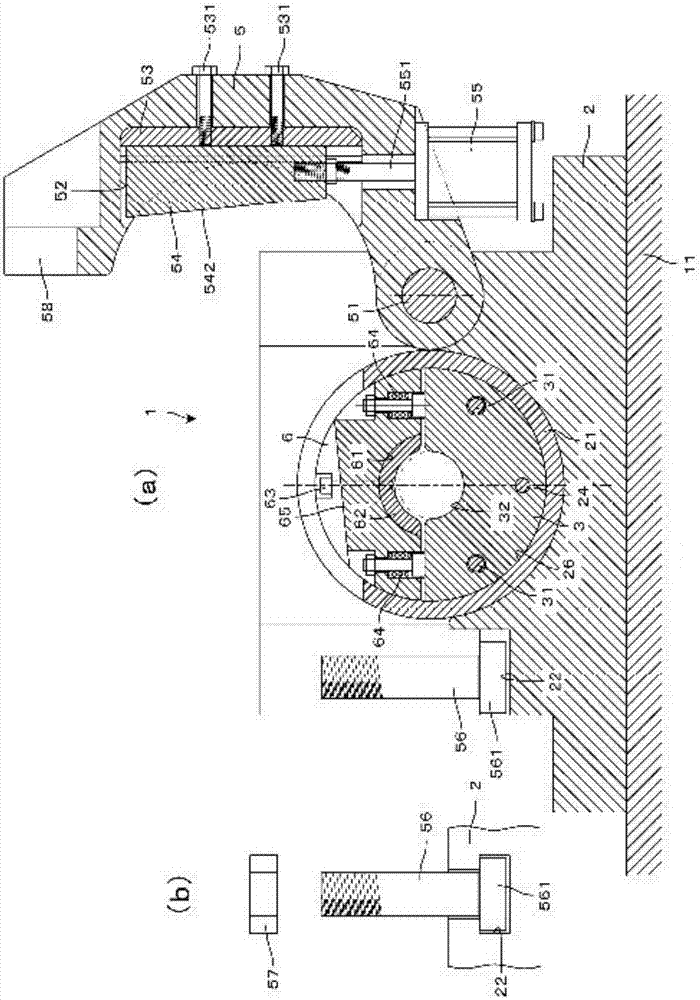

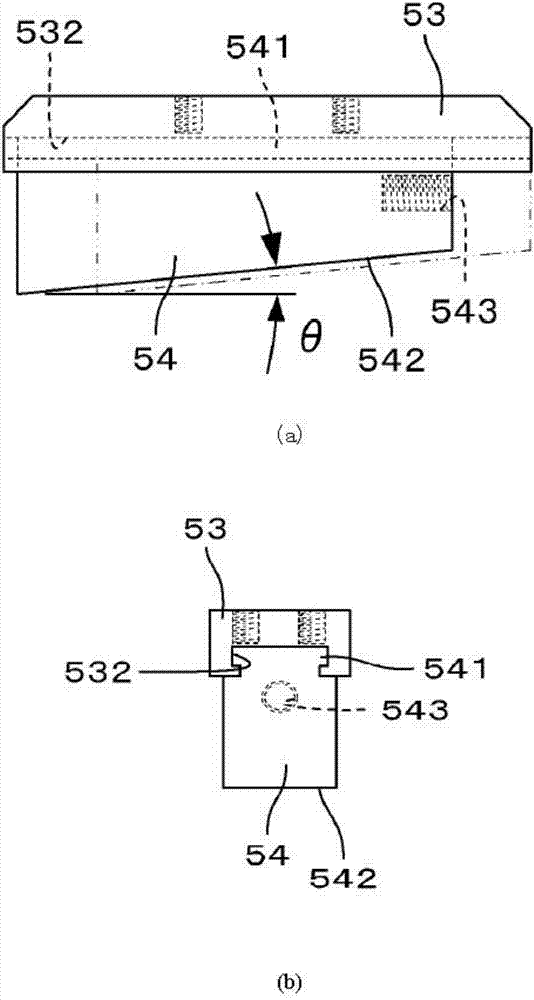

[0094] Embodiments of the present invention will be described below based on the drawings. figure 1 (a) is a longitudinal sectional front view showing a cutting device according to an embodiment of the present invention, figure 1 (b) is the bolt that fixes the clamping rod to the abutment figure 1 (a) Left side view. figure 2 yes figure 1 (a) A-A section view. image 3 (a) is a longitudinal sectional front view showing a state in which the clamp lever is swung to the replacement position, image 3 (b) is the bolt that fixes the clamping rod to the abutment image 3 (a) Left side view. Figure 4 yes means image 3 (a) is a front view of a longitudinal section in a state where the stationary knife and the pressing member are removed from the abutment. Figure 5 (a) is a front view showing a clamp block and a guide block, Figure 5 (b) is Figure 5 (a) Left side view. Figure 6 It is a front view showing the fixed knife and the movable knife.

[0095] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com