A contact structure and method for eliminating closing bounce

A closing bounce and contact technology is applied in the fields of detailed information of electromagnetic relays, electrical components, electromagnetic relays, etc. It can solve the problems that it is difficult to achieve no bounce of contacts, meet the requirements of reducing material performance and processing accuracy, eliminate bounce, Avoid the rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

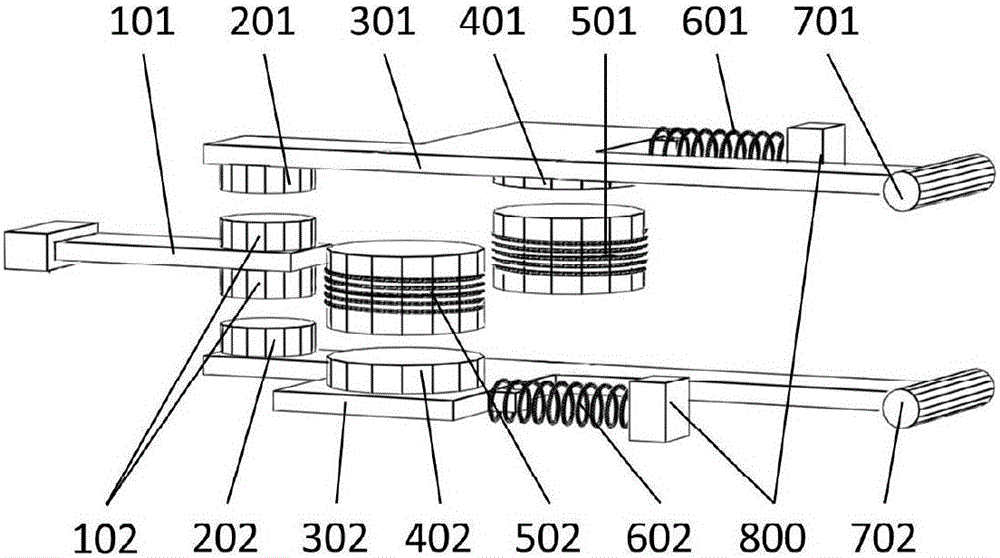

Image

Examples

Embodiment 1

[0027] The closure of the contact structure in the present invention:

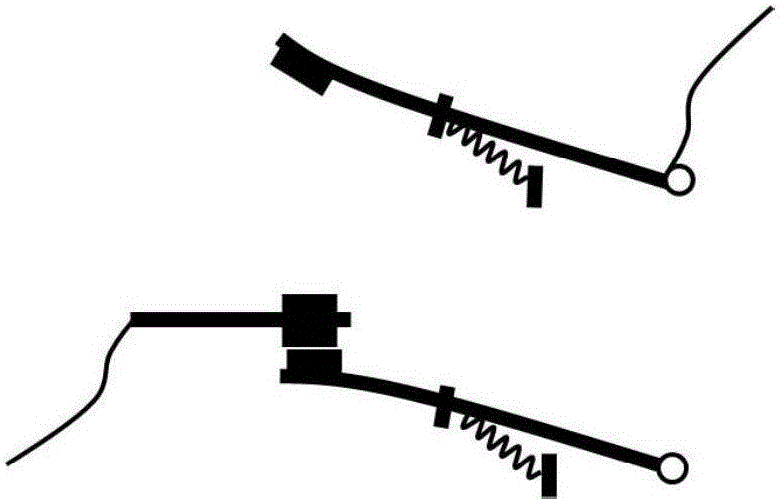

[0028] 1. The two ends of the grid line are respectively connected to the upper moving contact and the static contact, and the initial state is the line disconnected state, such as figure 2 As shown, the upper moving contact is separated from the static contact, and the lower moving contact is closed to the static contact;

[0029] 2. The first electromagnetic coil (501) is energized to generate a magnetic field, and the magnetic field attracts downward the first permanent magnet (401) fixed on the upper moving contact, and the upper moving contact moves downward against the force of the compression spring;

[0030] 3. When the first moving contact (201) at the front end of the upper moving contact collides with the fixed contact (102), an impact is generated instantly, and the impulse of the upper moving contact is transferred to the lower moving contact. A spring (601) maintains reliable contact with t...

Embodiment 2

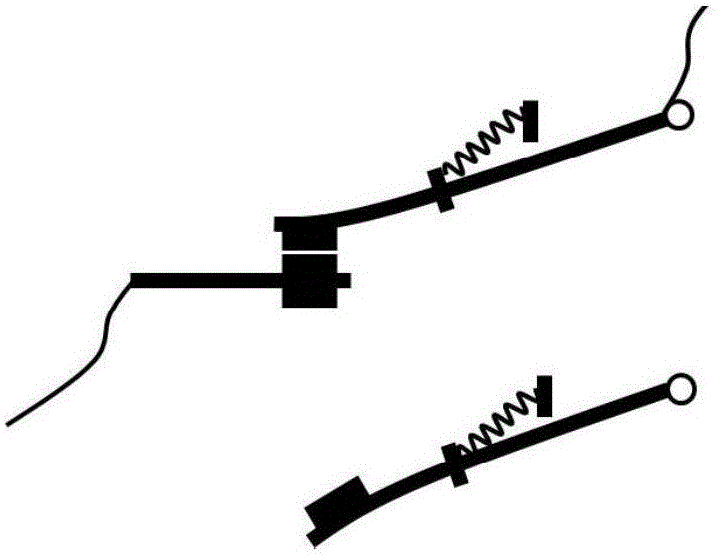

[0033] Disconnection of the contact structure in the present invention:

[0034] 1. The closed state of the line is as follows: image 3 As shown, the upper moving contact is connected to the static contact, and the lower moving contact is disconnected from the static contact;

[0035] 2. The first electromagnetic coil (501) is energized in reverse to generate a magnetic field, and the magnetic field generates an upward repulsion force on the first permanent magnet (401) fixed on the upper moving contact, and the force on the upper moving contact overcomes the force of the compression spring and moves upward to match the static force. The contacts separate and the grid line is disconnected.

[0036] 3. The second electromagnetic coil (502) is energized at the same time to generate a magnetic field, and the magnetic field generates an upward attractive force on the second permanent magnet (402) fixed on the lower moving contact. The static contact is closed.

[0037] From th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com