Patents

Literature

102results about How to "Reasonable organization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

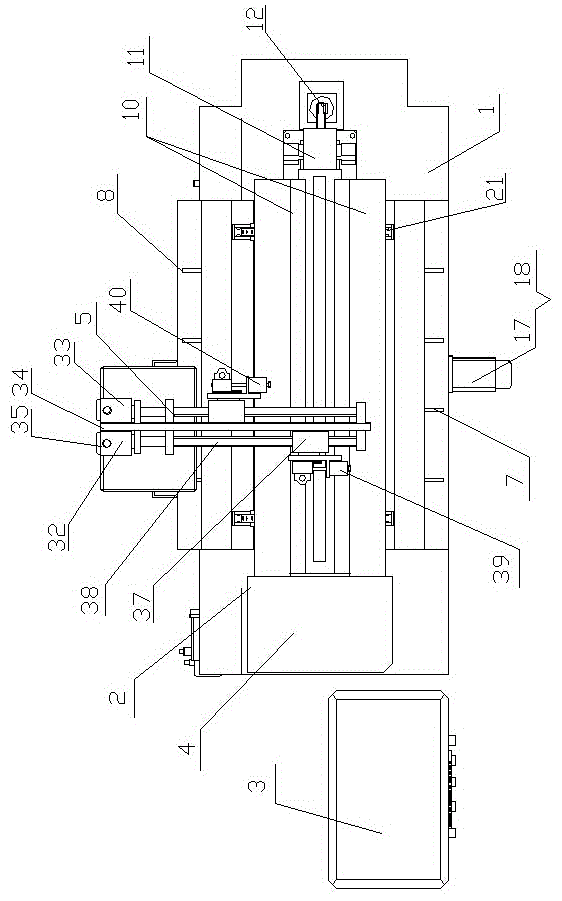

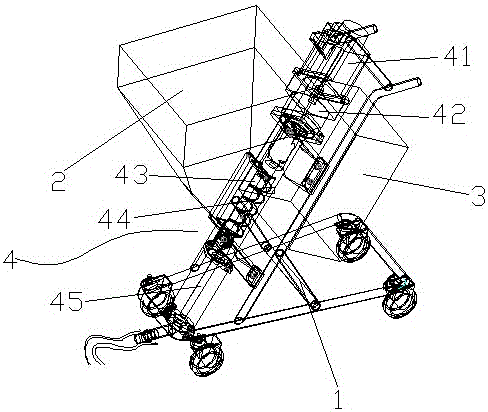

Anchor rod jacking drilling machine and anchor rod jacking drilling carriage with same

ActiveCN105443037AImprove locking abilityMechanizationDerricks/mastsAnchoring boltsUltimate tensile strengthTransferring (function)

The invention discloses an anchor rod jacking mechanism which comprises a fixing mechanism, a supporting mechanism, a sliding block and a drill box mechanism. The fixing mechanism comprises a base, a stand plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the stand plate. The supporting mechanism and the sliding block are in sliding connection with the opposite side faces of the stand plate through the guide blocks respectively. One end of the supporting mechanism and one end of the slide block are connected with base through telescopic oil cylinders. The drill box mechanism comprises a bottom frame and two independent drill box sliding seats. The bottom frame is connected with the base, and the drill box sliding seats can horizontally move along the bottom frame. When the drill box sliding seats move to the sliding block, the drill box sliding seats can be connected with the other guide rail face of the sliding block and slide along the sliding block. The invention further discloses an anchor rod jacking drilling carriage with a drilling machine. The anchor rod jacking drilling carriage comprises a four-wall anchor rod jacking drilling carriage body and a six-arm anchor rod jacking drilling carriage body. The drilling machine in the anchor rod jacking drilling carriage can work at the same time. Fast supporting operation on a top plate can be achieved, the structure is compact, and multiple functions are achieved. The anchor rod jacking mechanism and the anchor rod jacking drilling carriage operate in cooperation with heading equipment to complete the supporting and transferring function synchronously, operating personnel are greatly reduced, the labor intensity is lowered, and the supporting efficiency and safety are improved.

Owner:蒲长晏

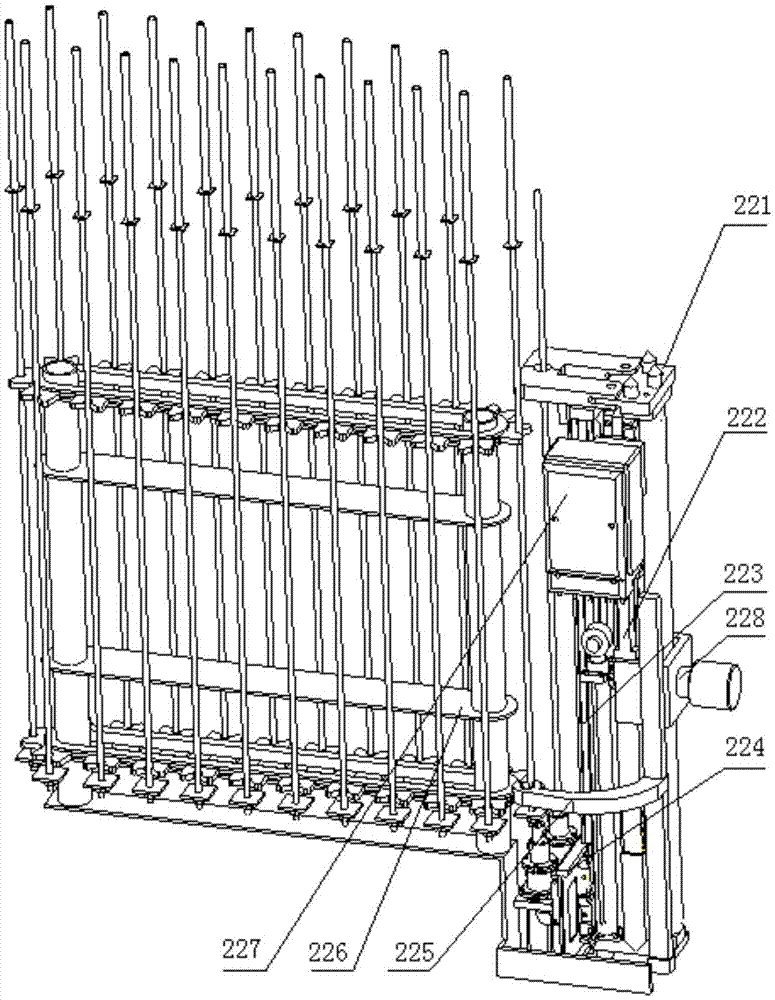

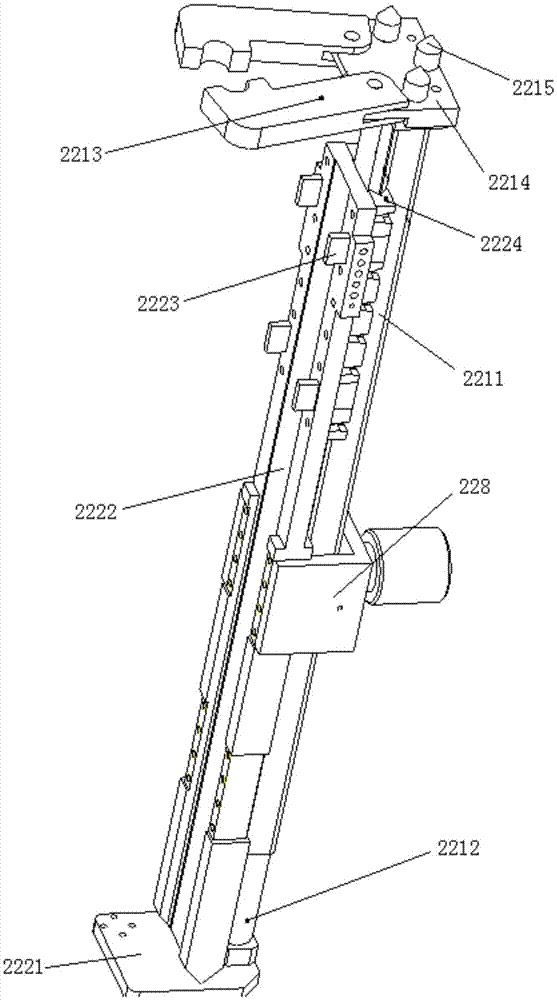

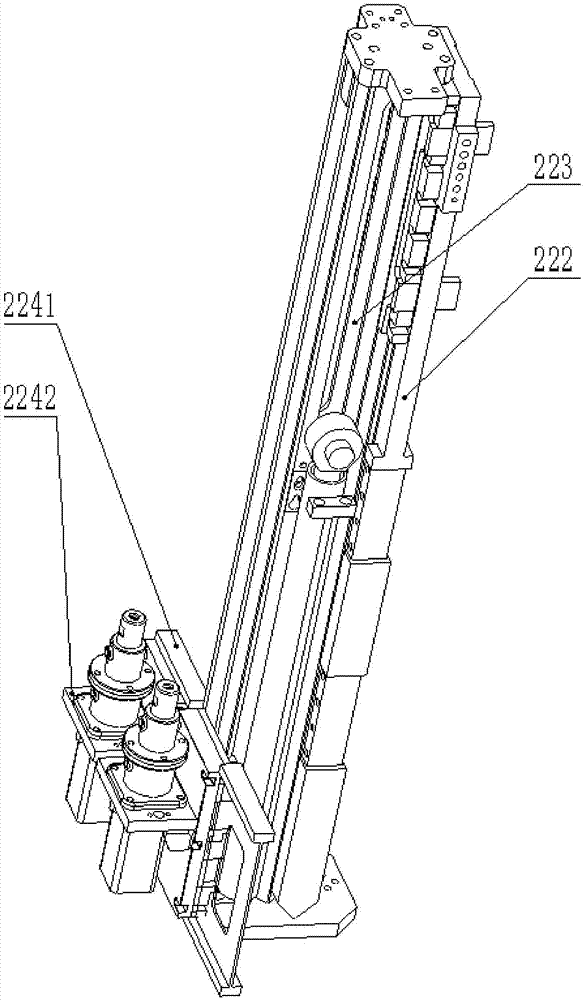

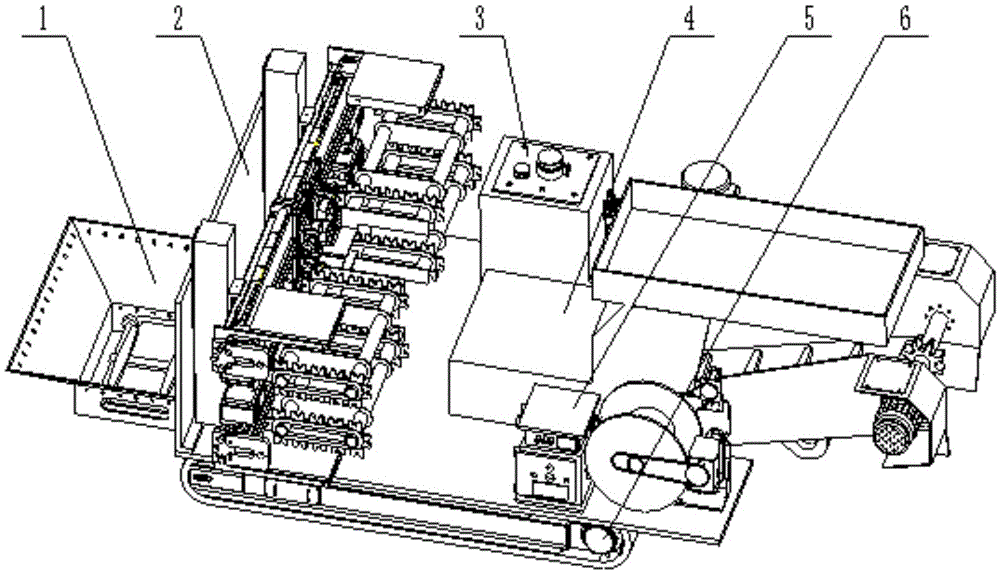

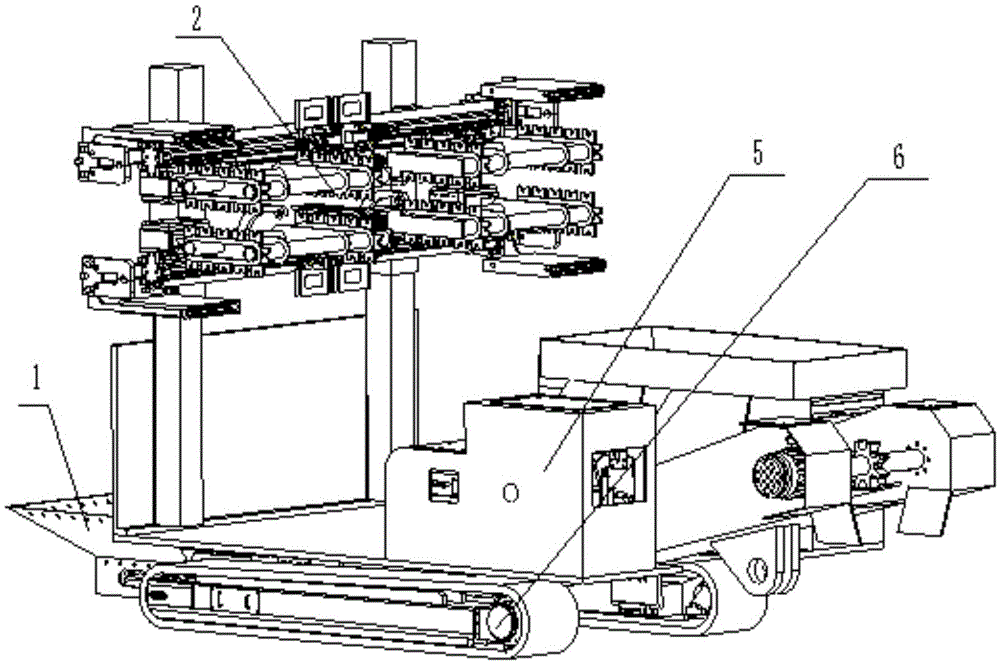

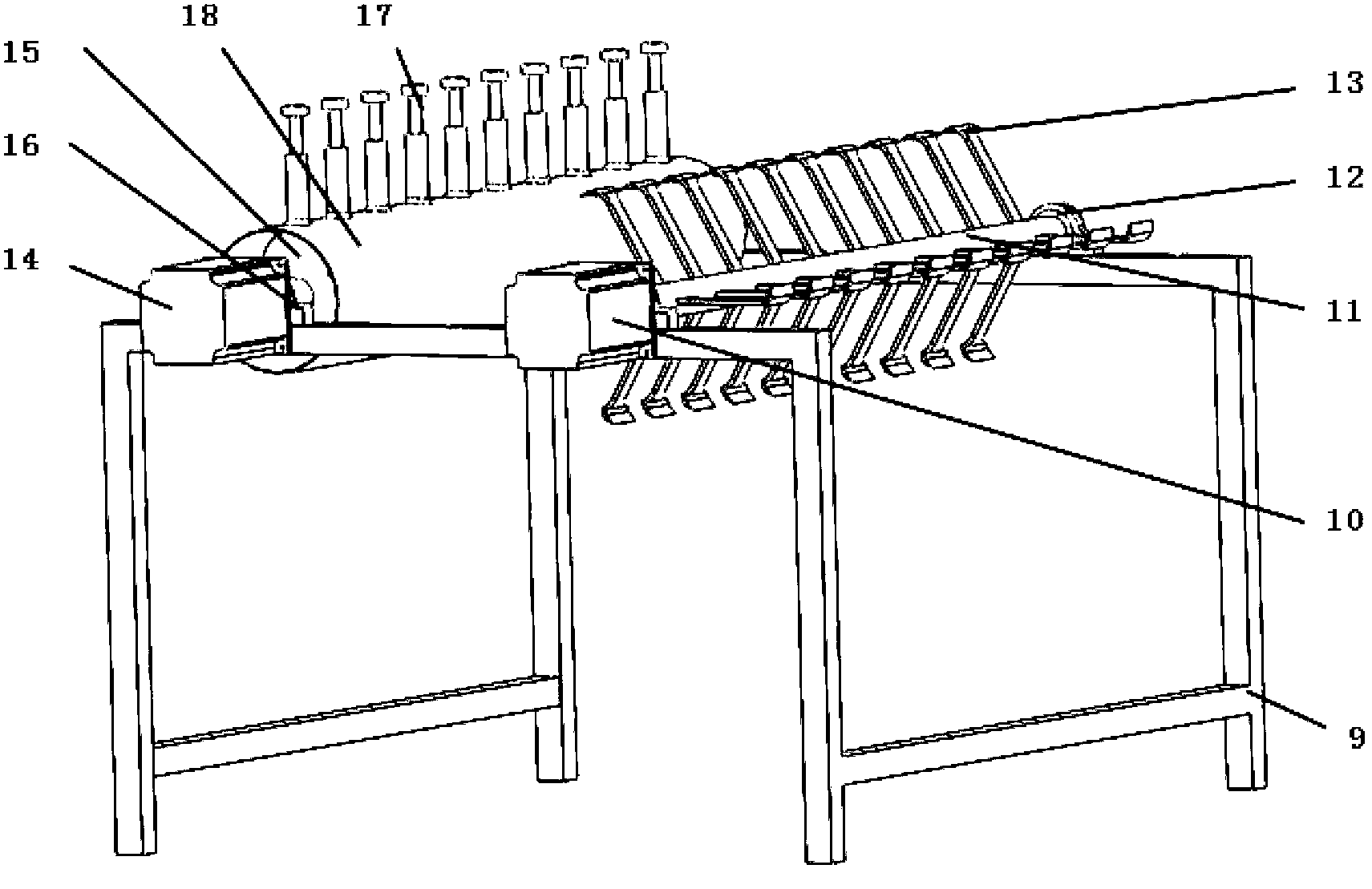

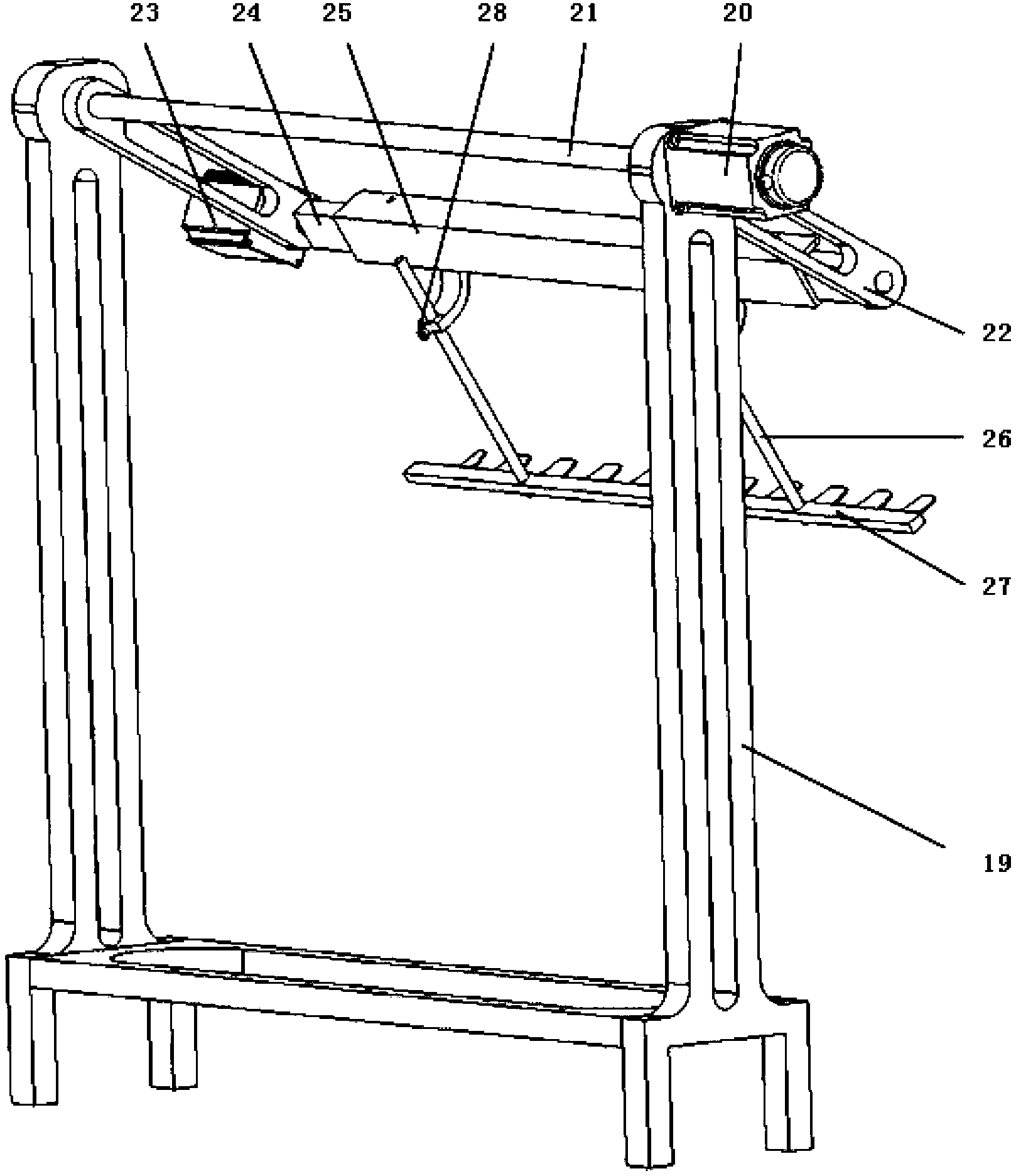

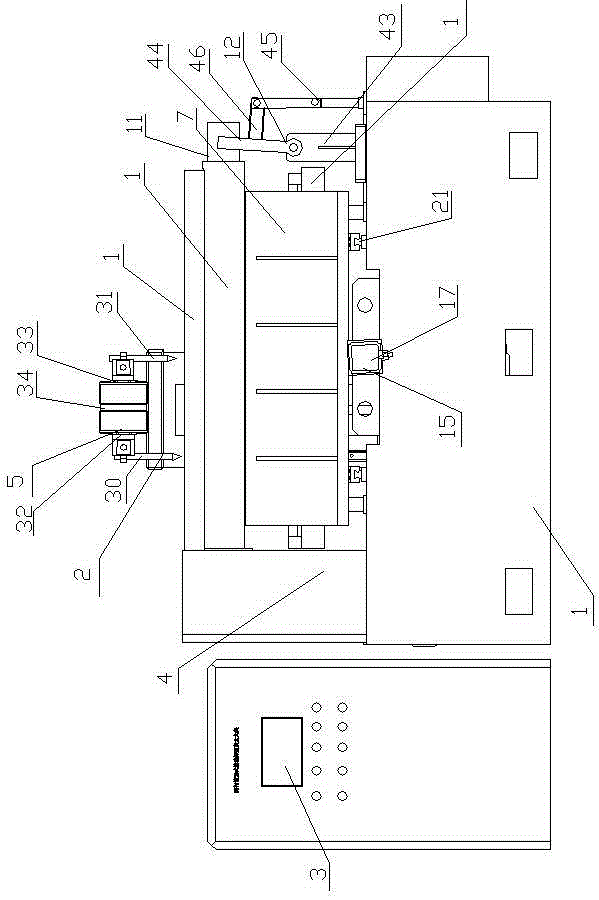

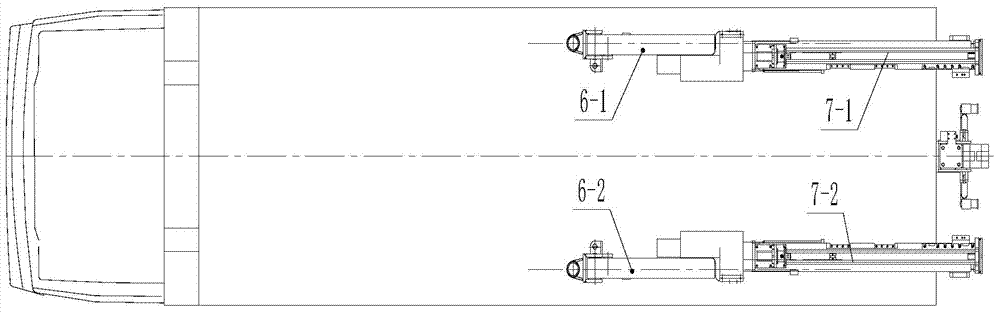

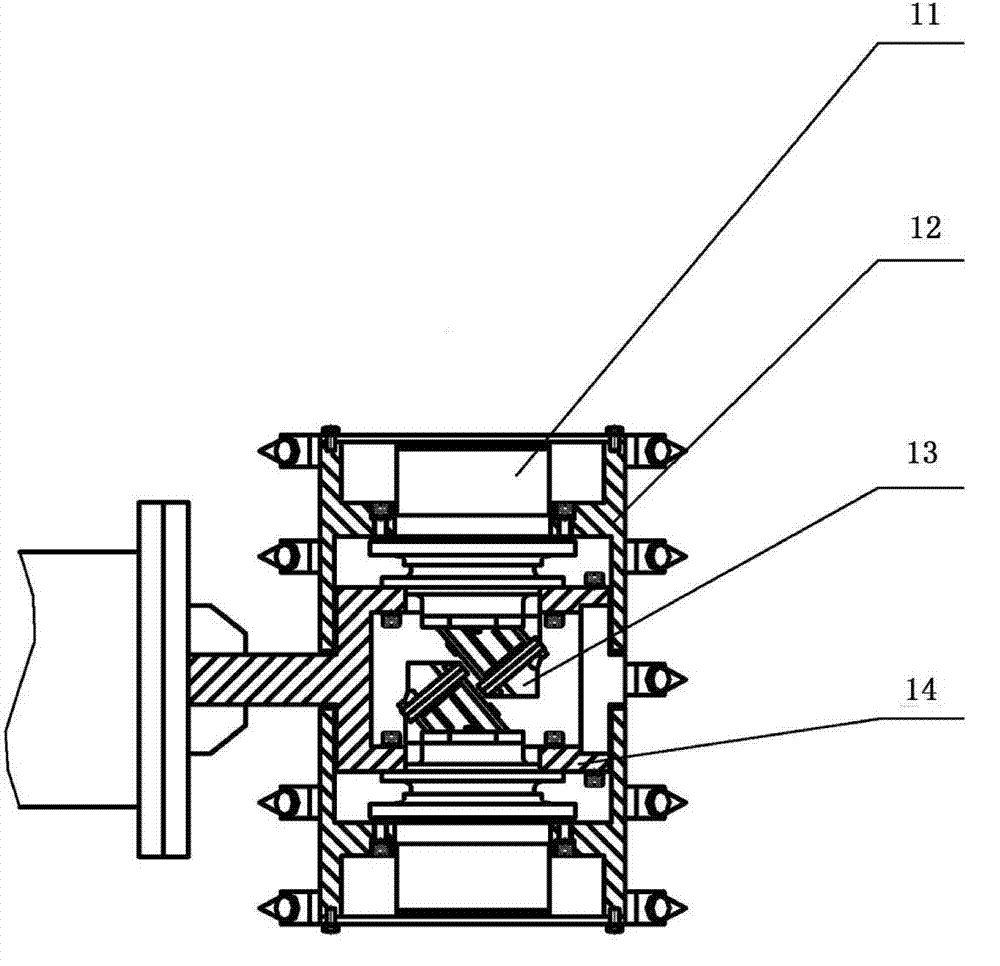

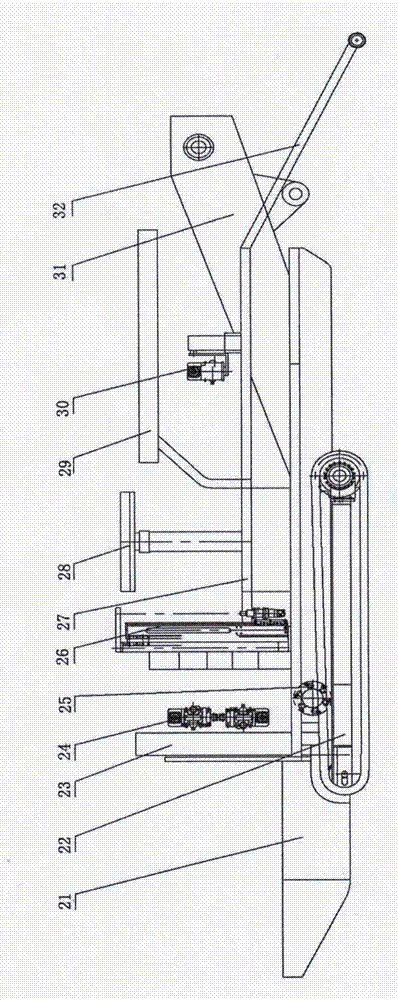

Side bolt drilling machine and side bolt drilling carriage with same

ActiveCN105626108ALarge storage capacityMeet construction needsDerricks/mastsAnchoring boltsEngineeringRock bolt

The invention discloses a side bolt drilling machine which comprises a fixing mechanism, a supporting mechanism, a sliding rack, a drilling box mechanism and a cartridge conveying box. The fixing mechanism comprises a base, a vertical plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the vertical plate. The supporting mechanism and the sliding rack are in sliding connection with the opposite side faces of the vertical plate respectively through the guide blocks, and one end of the supporting mechanism and one end of the sliding rack are connected with the base through a telescopic oil cylinder. The drilling box mechanism comprises a bottom rack and two independent drilling box sliding seats. The bottom rack is fixedly connected with the base, the drilling box sliding seats can horizontally move along the bottom rack, and when the drilling box sliding seats move to the sliding rack, the drilling box sliding seats can be connected with the other guide rail face of the sliding rack and slide along the sliding rack. The cartridge conveying box is used for completing the automatic cartridge feeding procedure of the drilling machine. The invention further discloses a side bolt drilling carriage with the drilling machine. By means of automatic cartridge feeding and automatic anchor bolt mounting, mechanization and automation of anchor bolt supporting work are achieved, the construction needs of a plurality of rows of side bolts can be met, and the side bolt drilling carriage works in cooperation with heading equipment to synchronously complete side bolt supporting and transferring functions.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

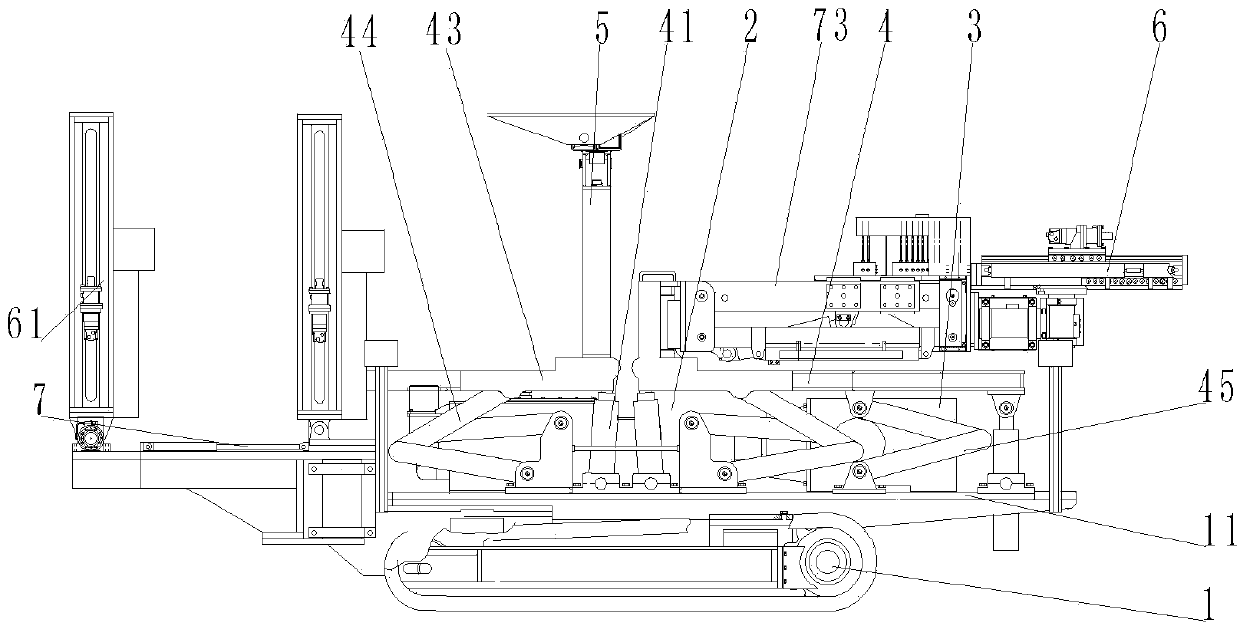

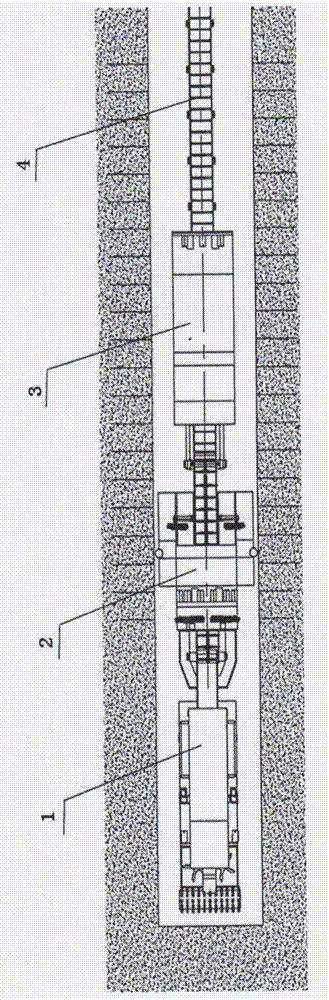

Railway tunnel anchor jumb drill

The invention discloses a railway tunnel anchor jumb drill, which comprises a traveling mechanism, a rotating chassis arranged on the traveling mechanism, a lifting platform arranged on the chassis, a rotating drill arm mechanism arranged on the lifting platform, a rotating drilling mechanism arranged on the drill arm mechanism and a power system for driving the traveling mechanism, the chassis, the lifting platform, the drill arm mechanism and the drilling mechanism to act. According to the railway tunnel drill jumb drill, railway tunnel anchor construction equipment is specialized for the first time, the railway tunnel drill jumb drill is reasonable in overall structure and diversified in function, tunnel anchor construction can be mechanized, the labor intensity of a worker can be reduced, construction quality, accuracy and efficiency can be improved, and project quality can be better ensured.

Owner:蒲长晏

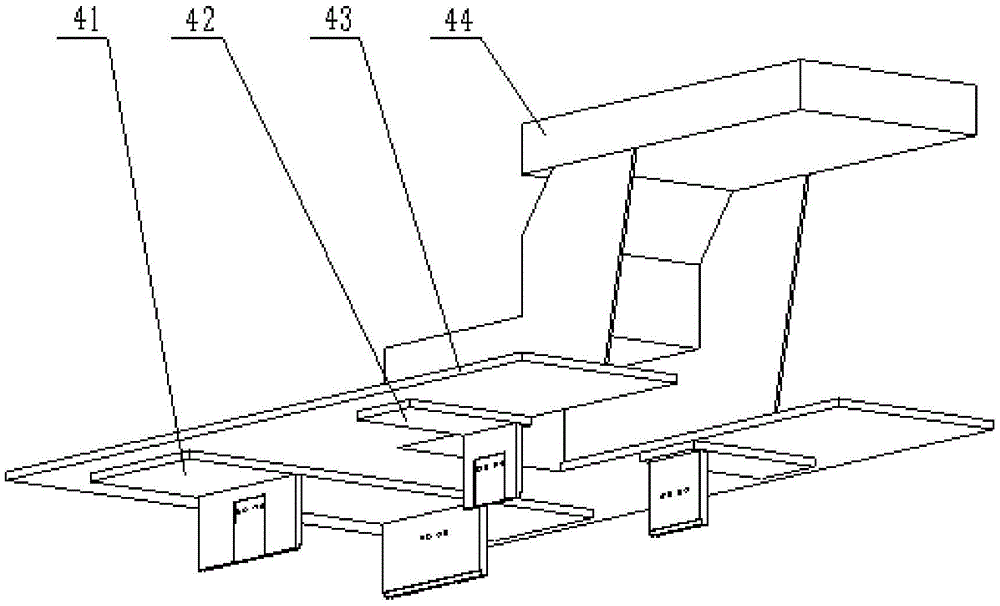

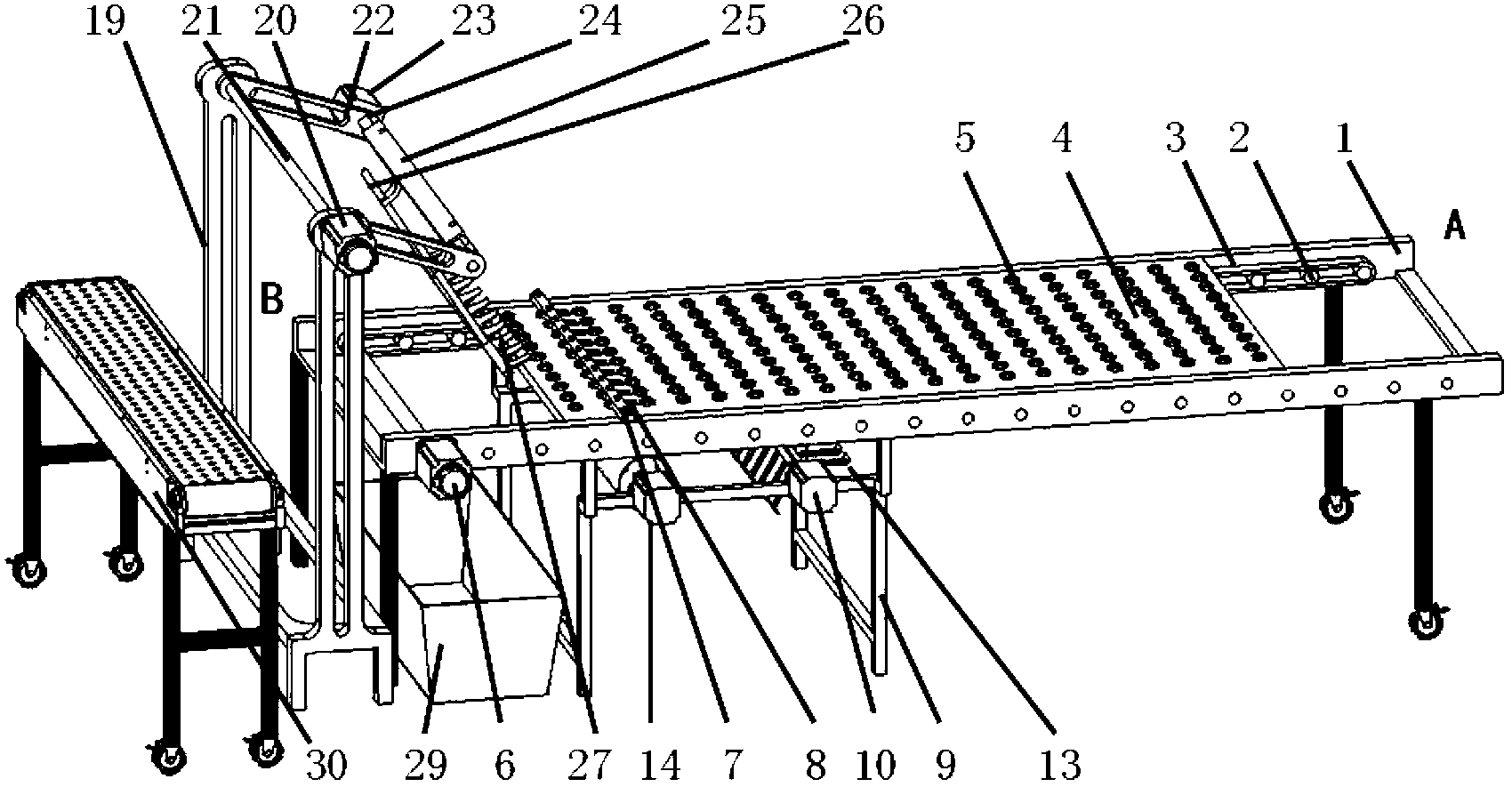

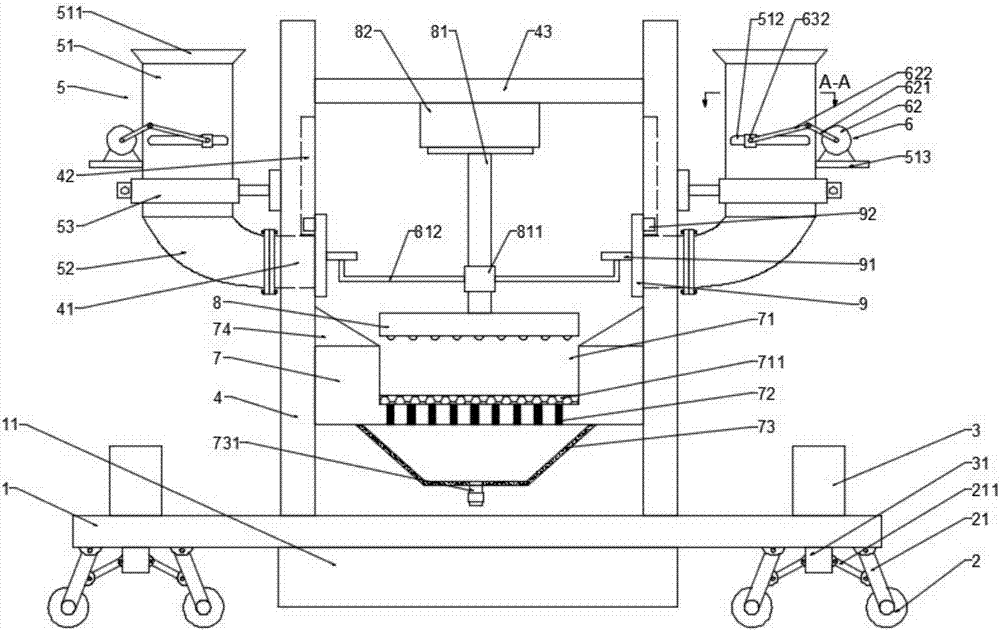

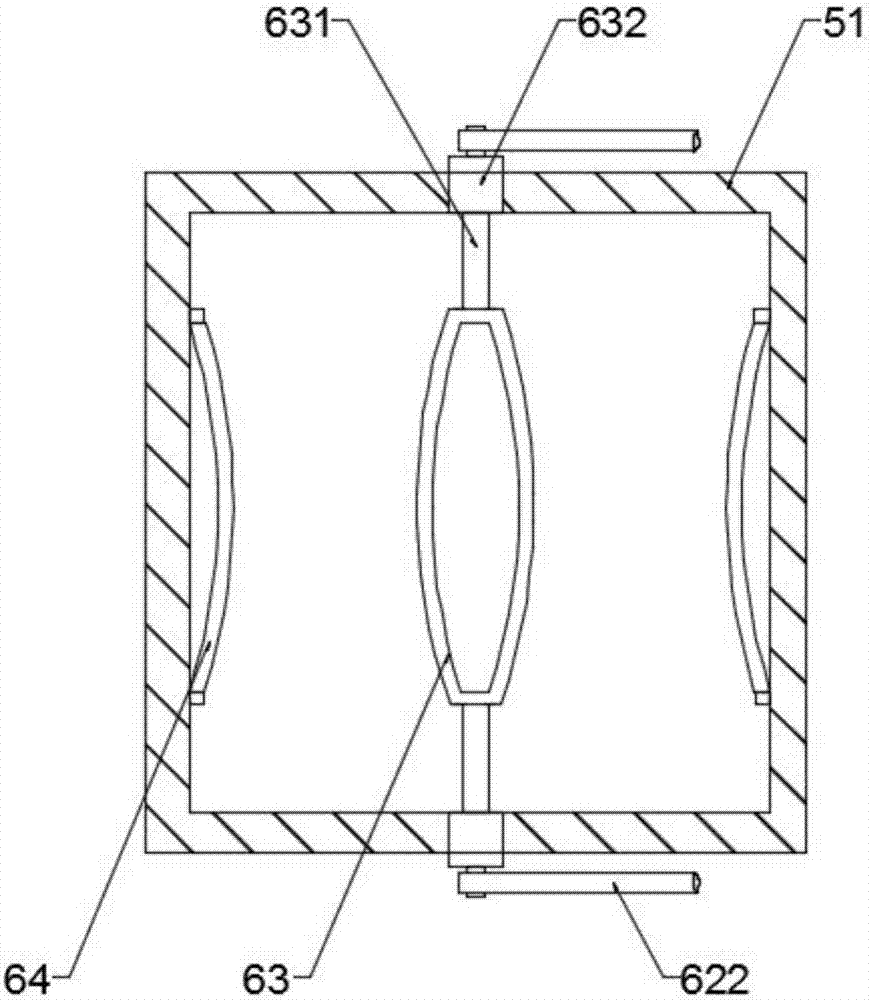

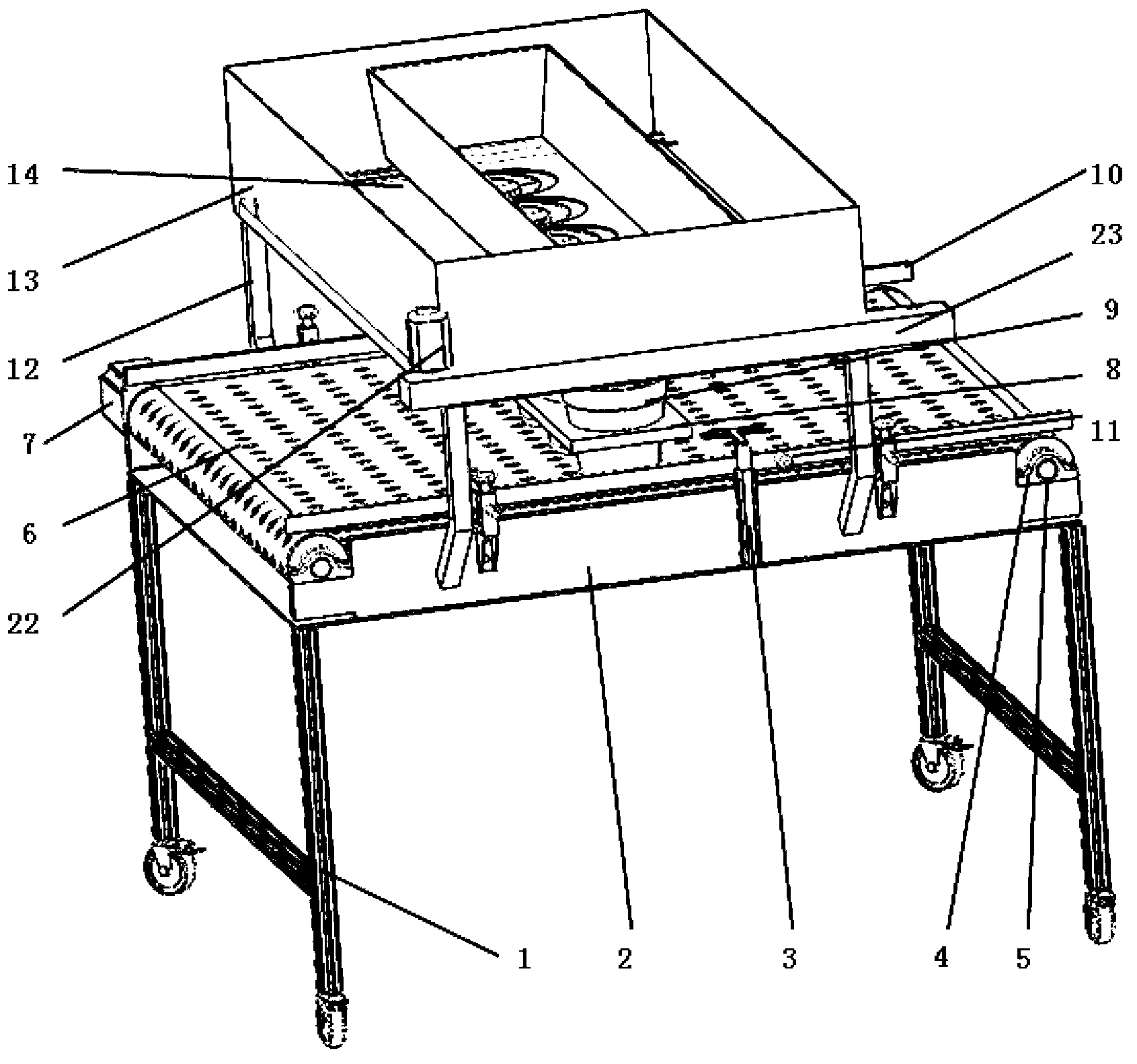

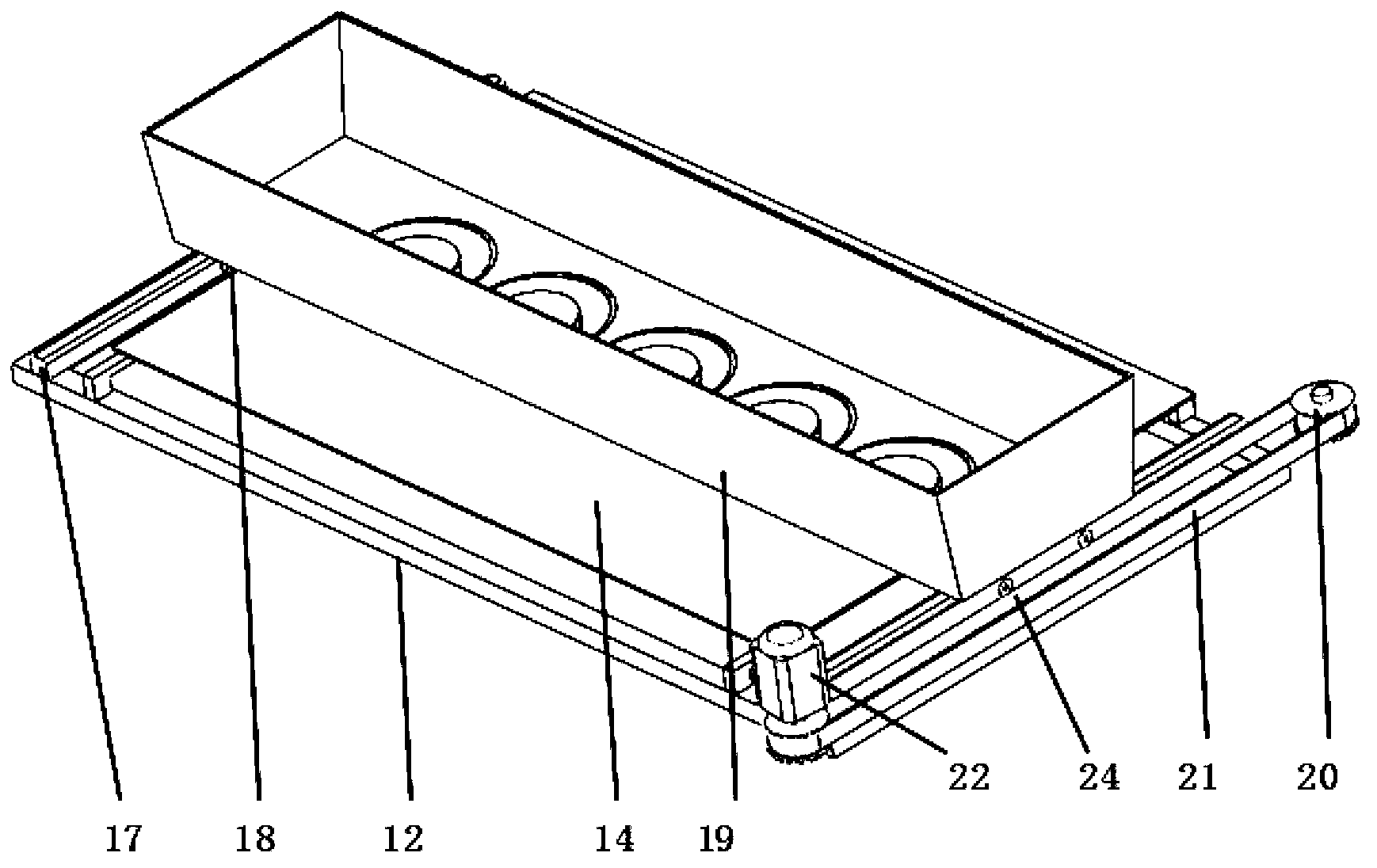

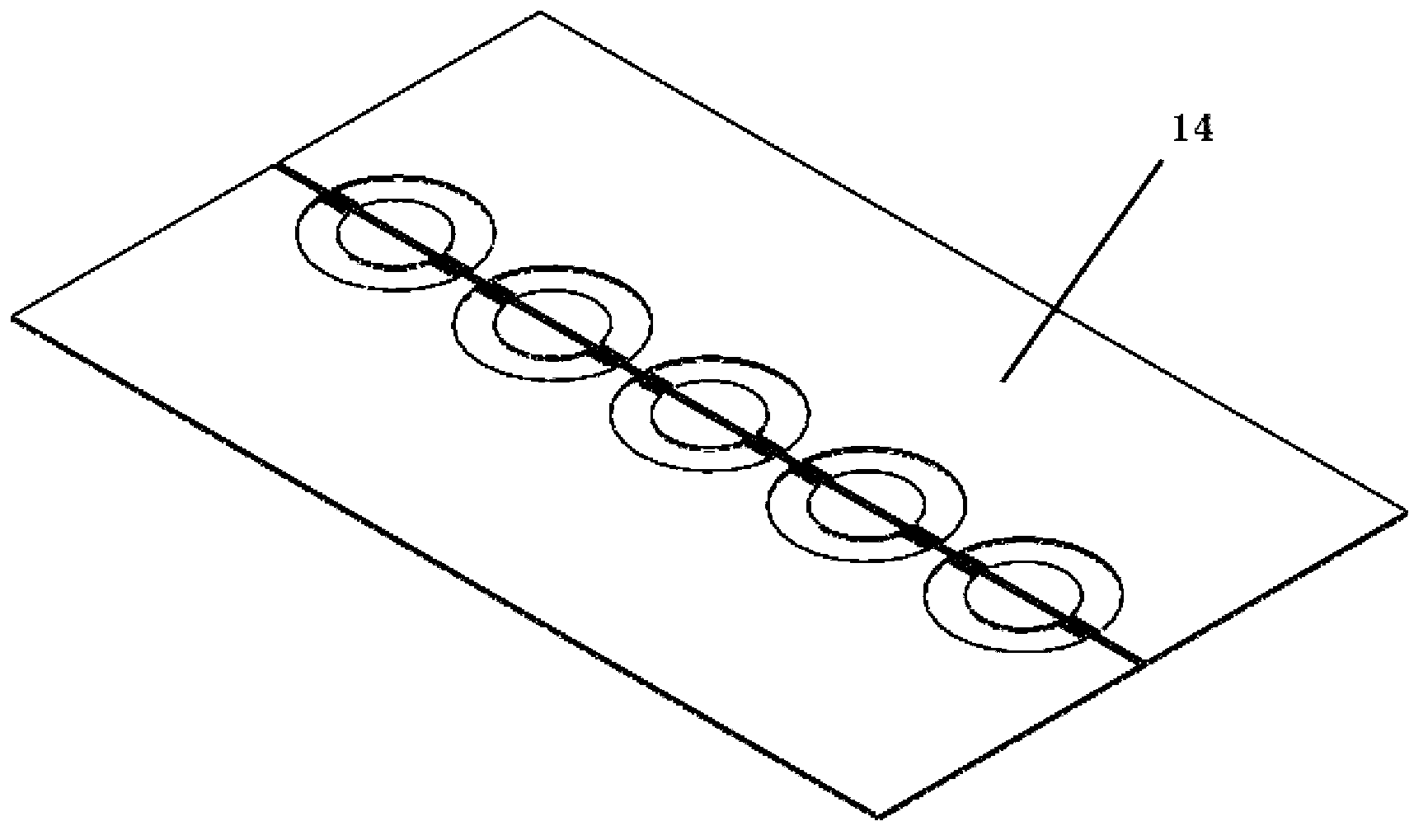

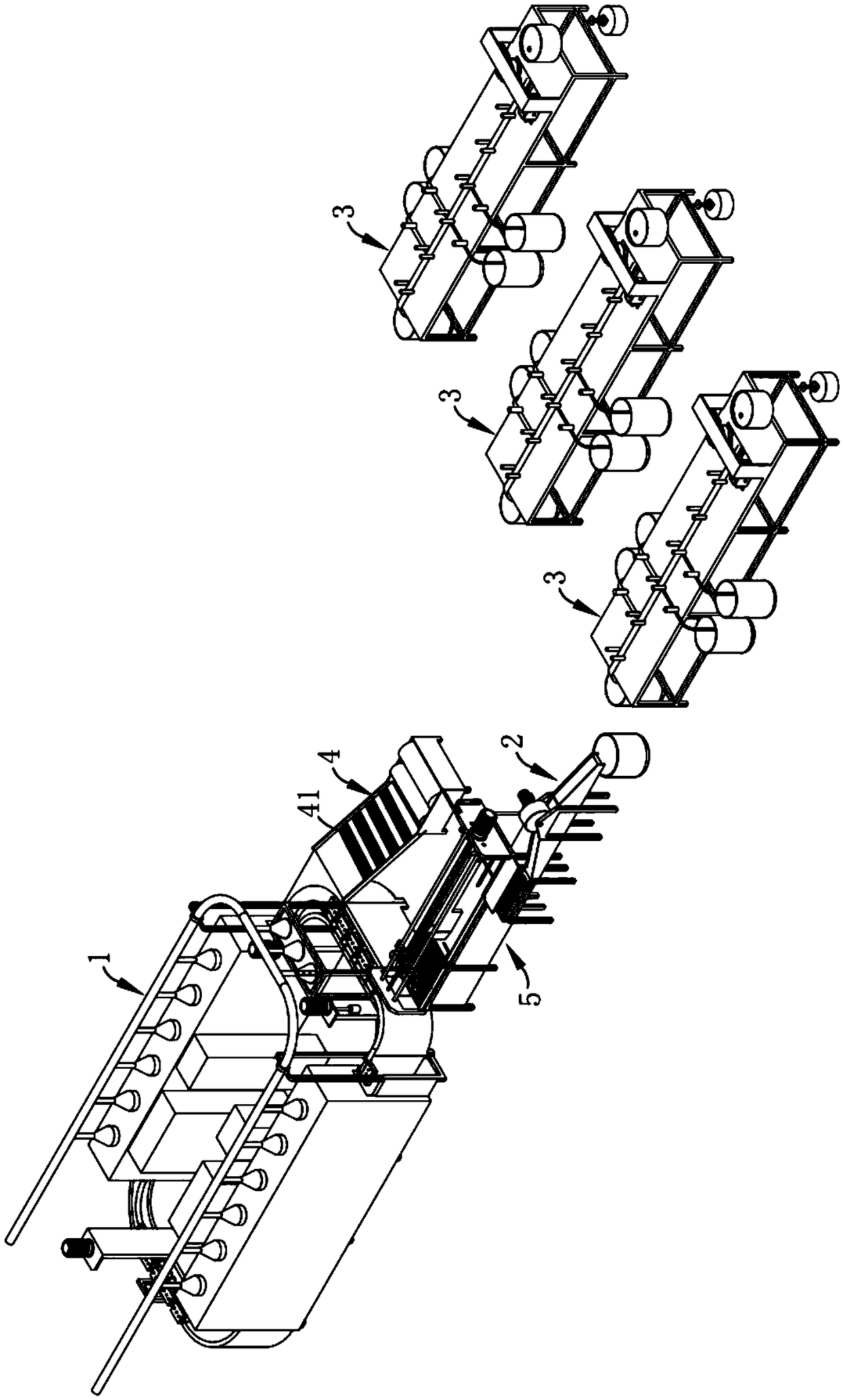

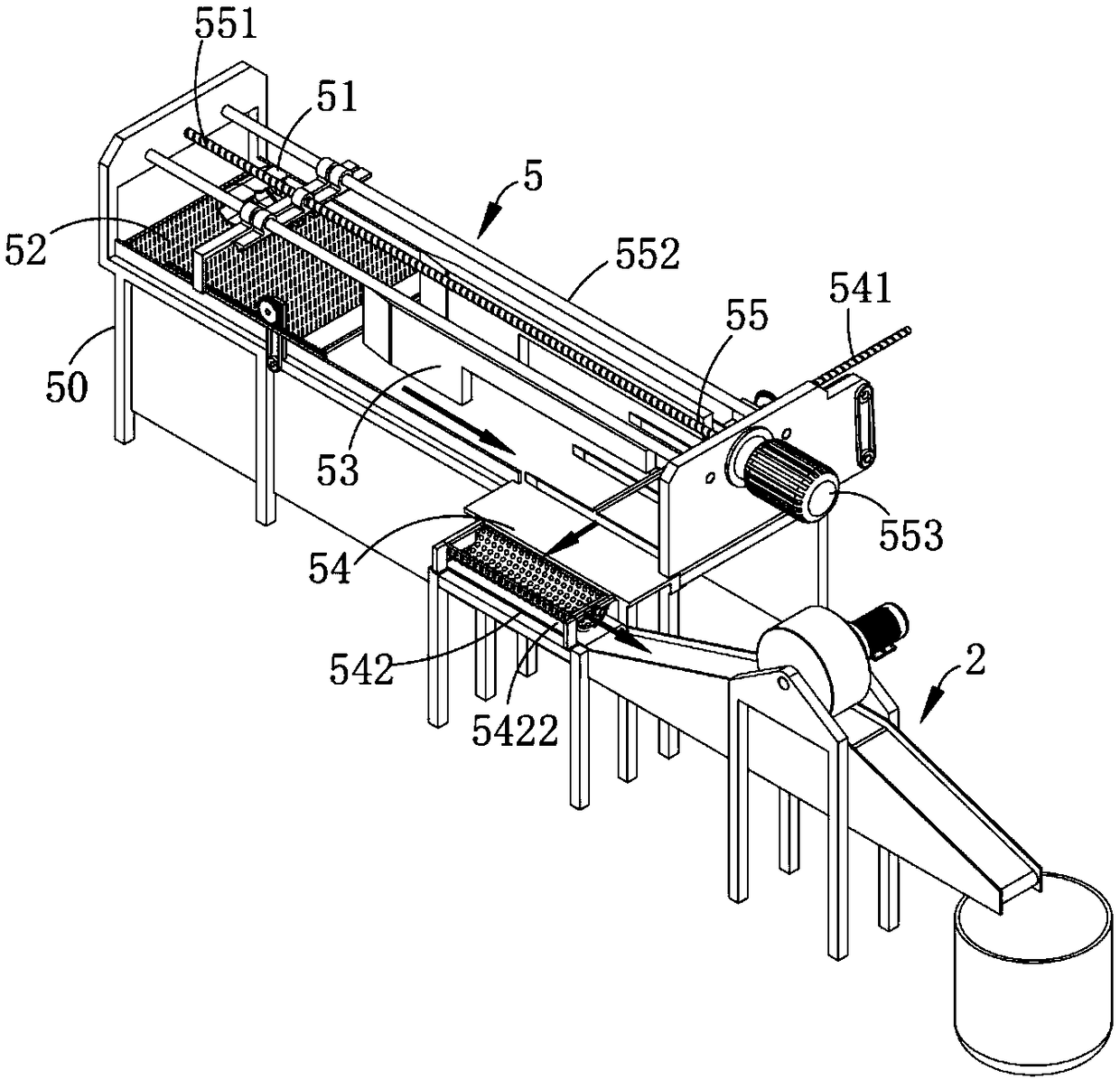

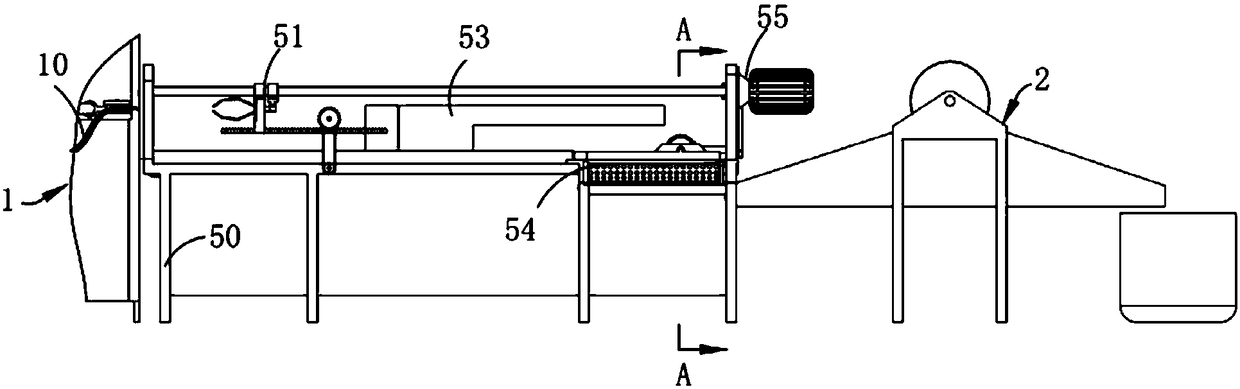

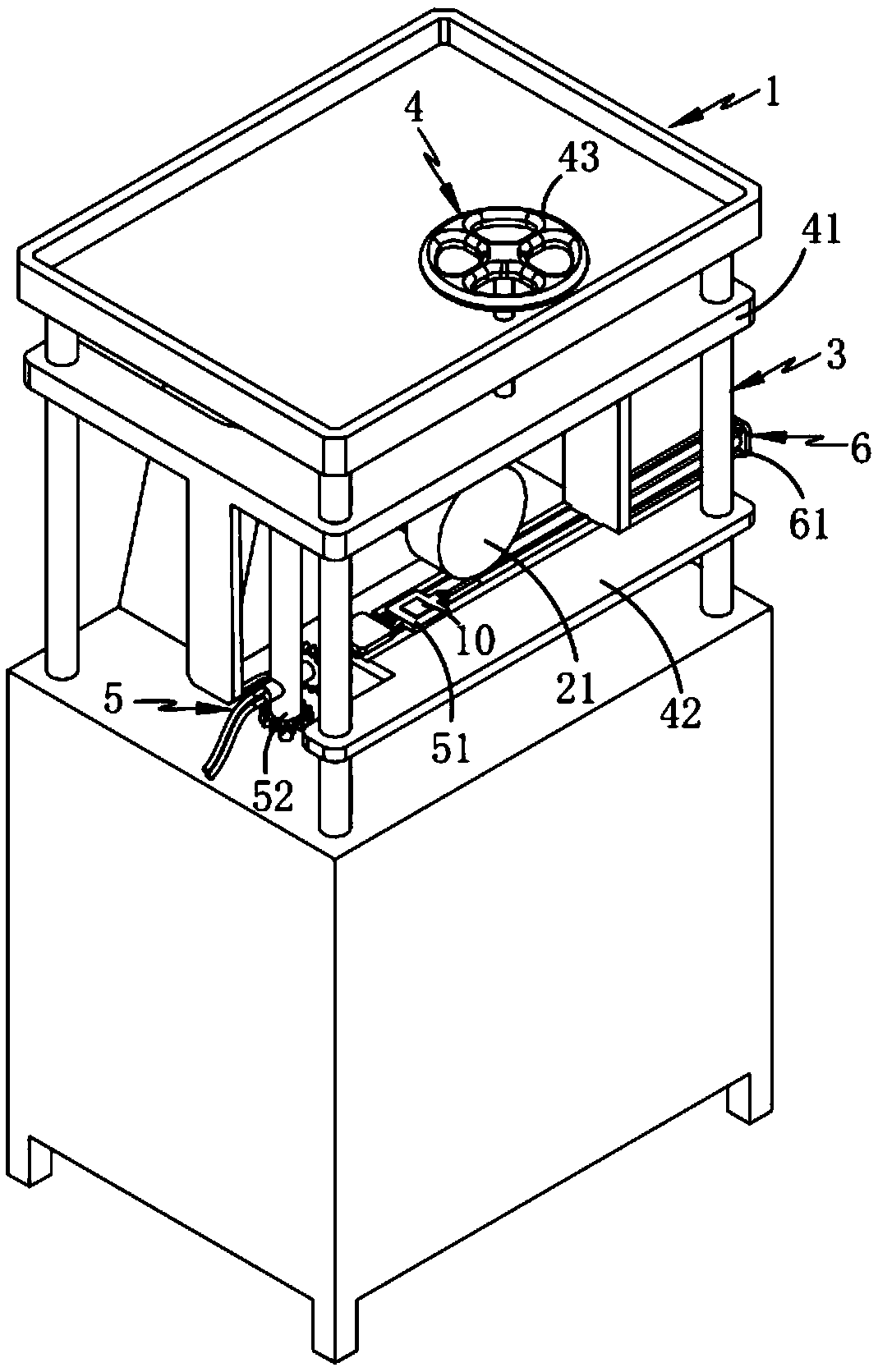

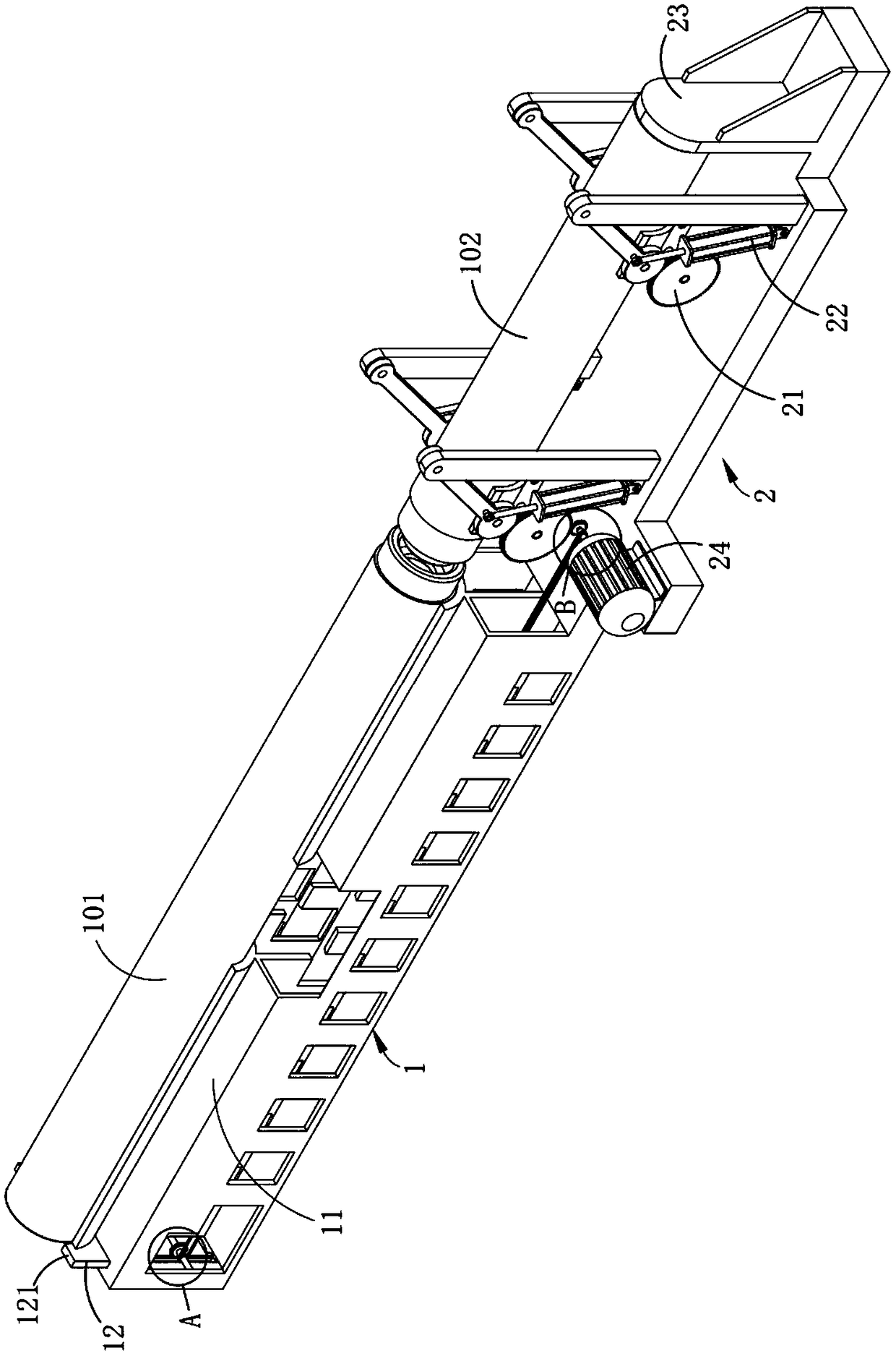

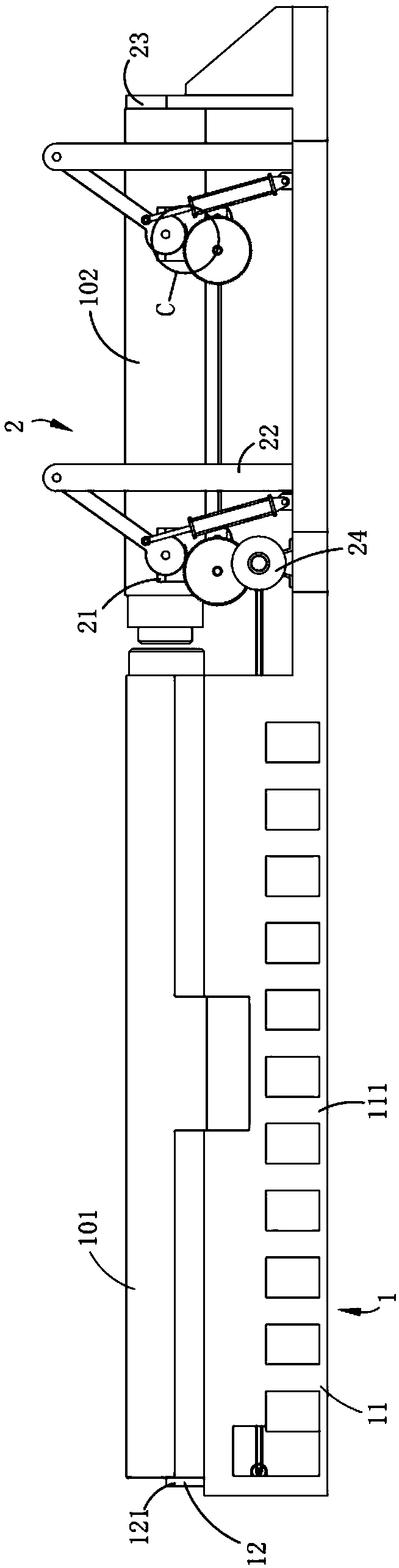

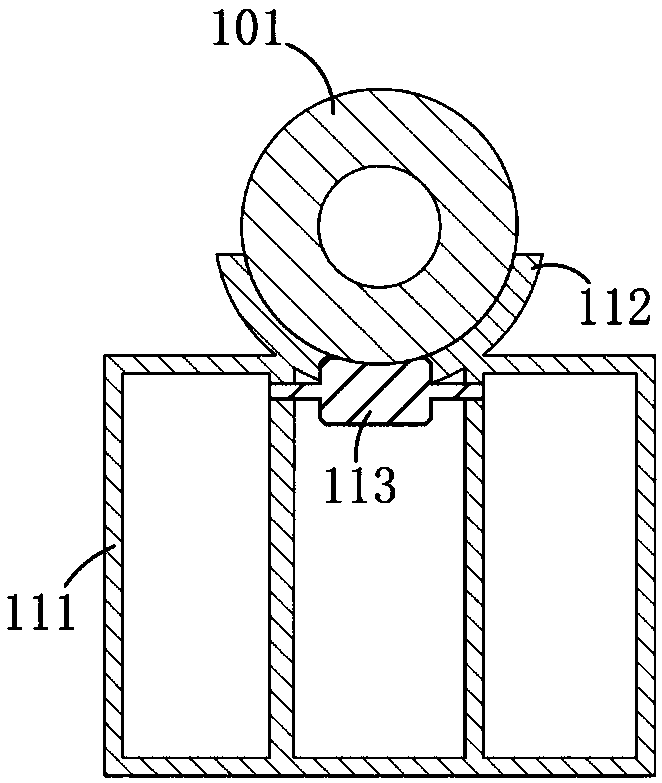

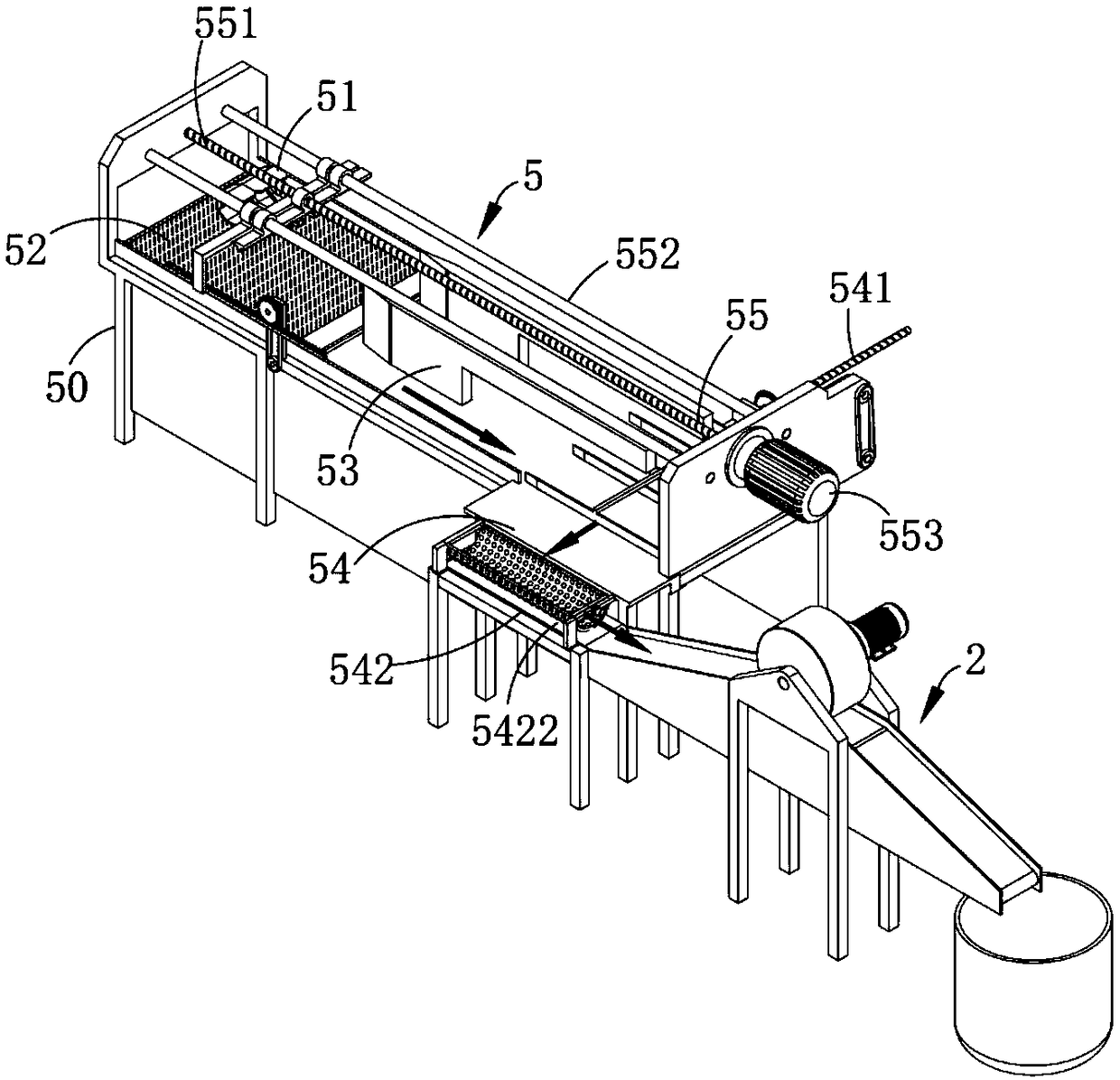

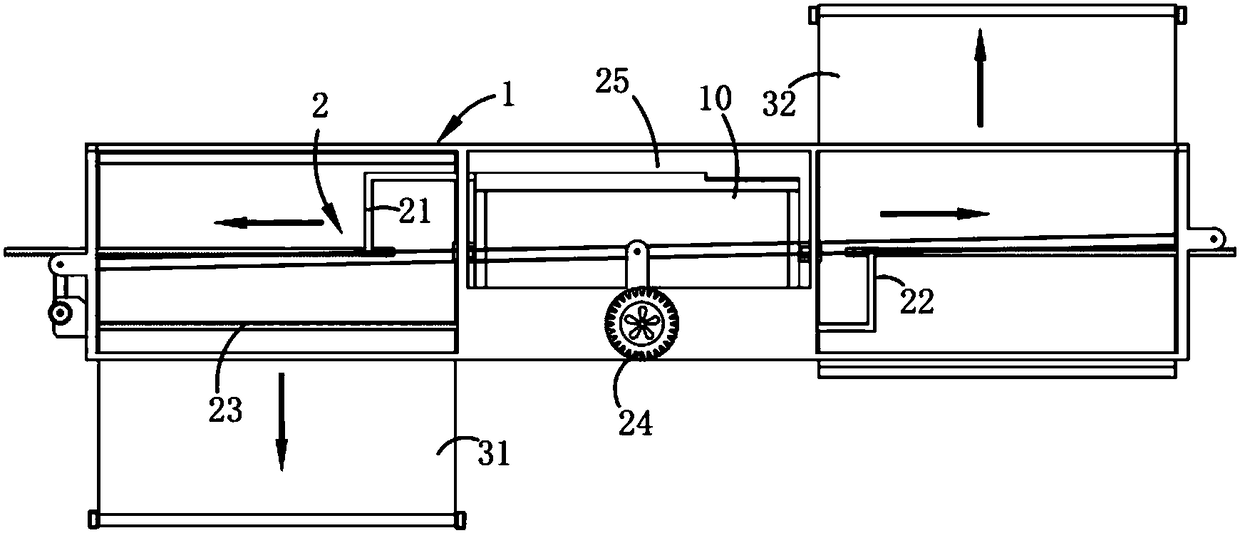

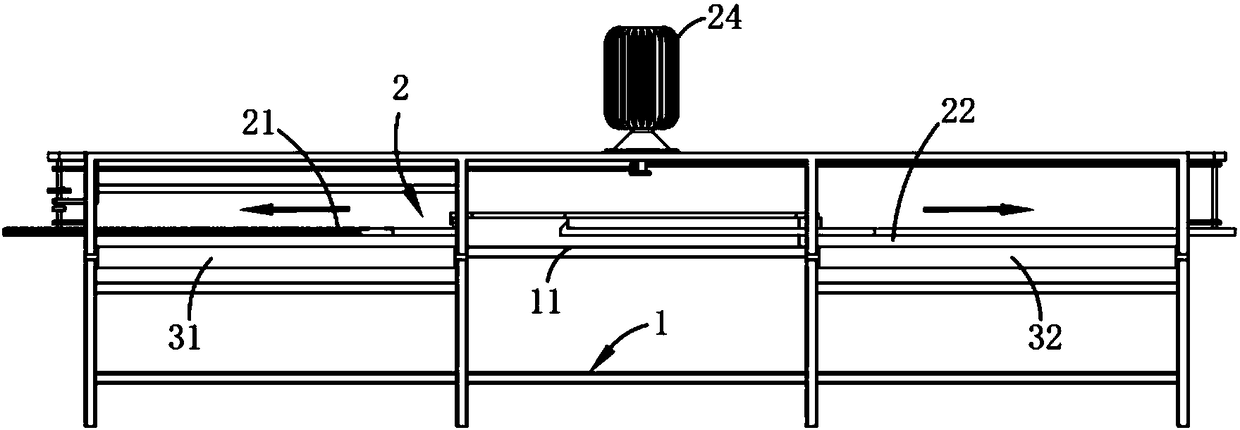

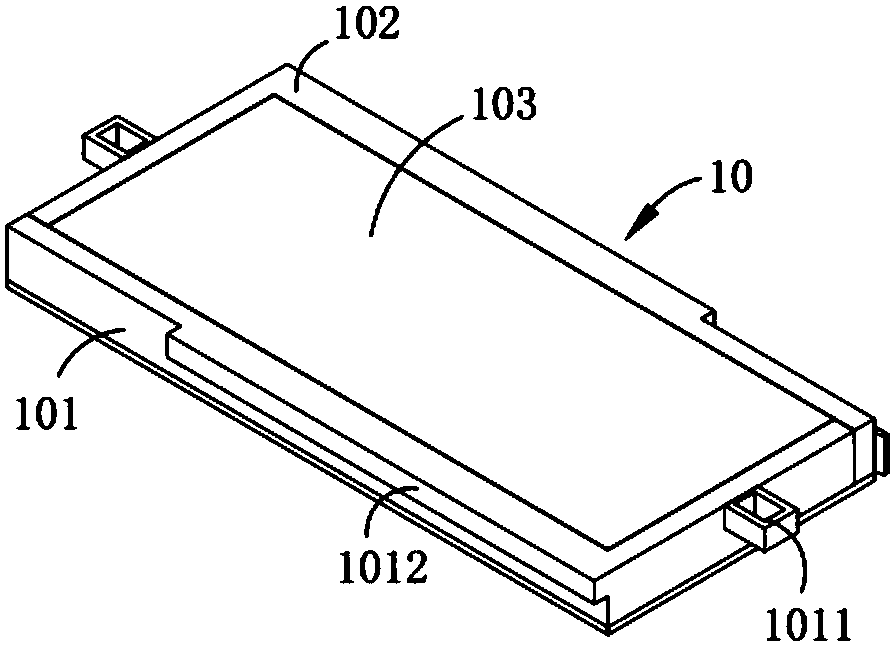

Root cutting harvest device for vegetables planted by modern greenhouse atomization

ActiveCN103262705AReasonable organizationEasy to install and maintainHarvestersGreenhouseEngineering

The invention discloses a root cutting harvest device for vegetable planted by modern greenhouse atomization, and belongs to the field of facility agriculture automation. The root cutting harvest device comprises a conveying mechanism, a root cutting mechanism, a transferring mechanism, a cup pressing mechanism and a cup ejecting mechanism. Vegetables are planted in a planting cup. A benzene plate is conveyed to a working position by the conveying mechanism. Vegetables growing on the benzene plate are subjected root cutting by the root cutting mechanism. Vegetables with roots cut are transferred by the transferring mechanism to a conveying belt to perform a next operation. The planting cup is still kept in a hole of the benzene plate by the cup pressing mechanism in a transferring process. The planting cup is ejected out of the hole of the benzene plate by the cup ejecting mechanism so as to drop into a planting cup recycling case. By the aid of the root cutting harvest device, root cutting harvest of different vegetables can be realized, processes such as spraying, disinfection and packaging can further be introduced after root cutting and clearing are finished. The root cutting harvest device is high in automatic degree, and easy and reliable to operate.

Owner:曹伟鹏 +1

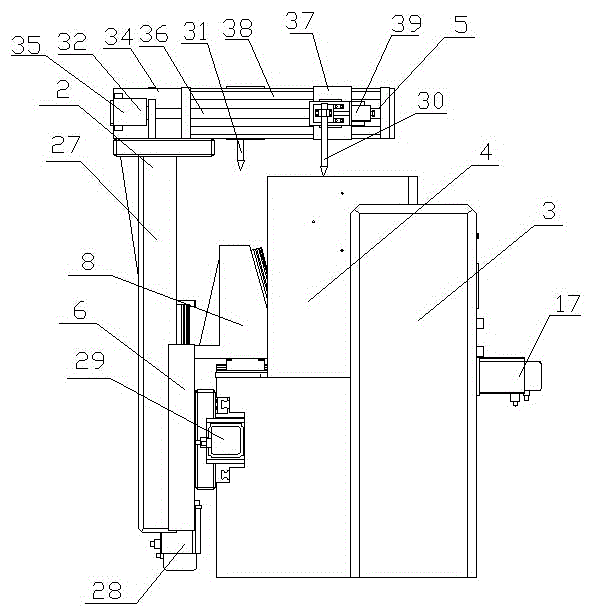

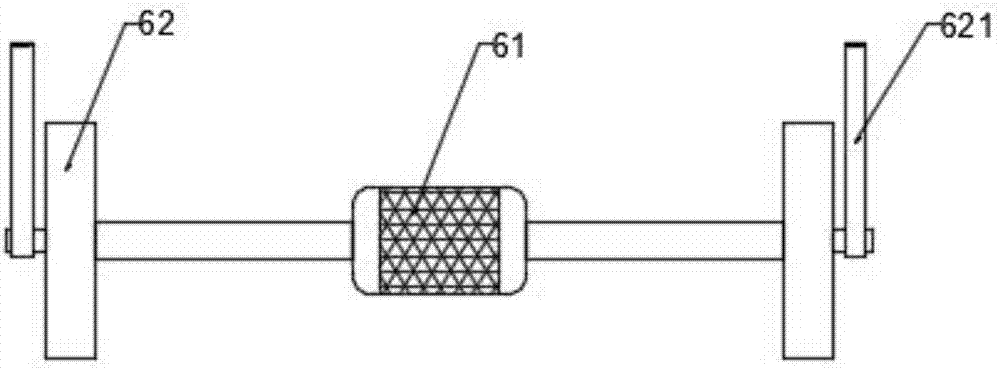

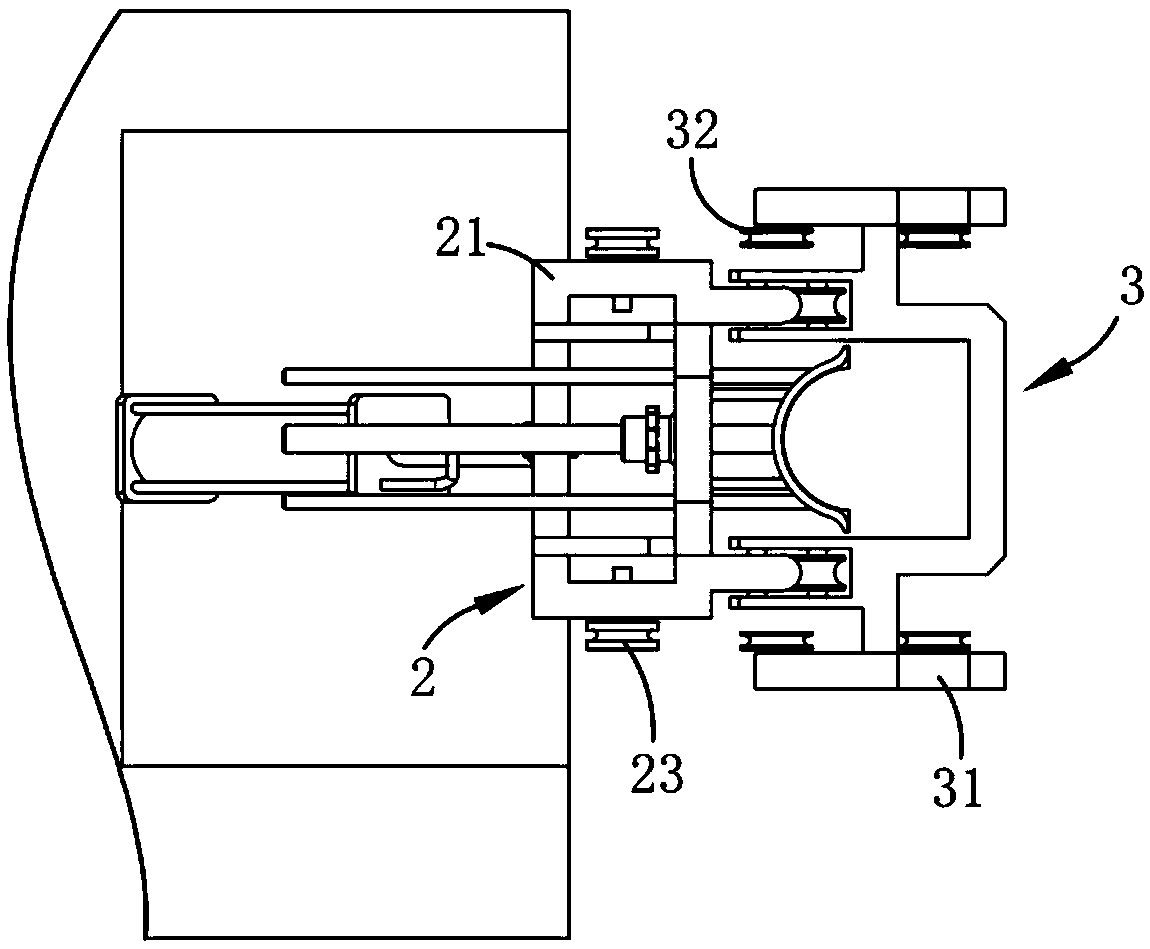

Compound pipe longitudinal joint automatic welding device

InactiveCN105127541AAchieve axial positioningImprove continuityTubular articlesSoldering auxillary devicesKey pressingControl system

The invention relates to the technical field of welding, in particular to a compound pipe longitudinal joint automatic welding device which mainly comprises a double welding gun movement mechanism, a control system, welding power supplies and a welding fixture. The double welding gun movement mechanism is composed of a movable platform, a left welding gun, a right welding gun and a cross sliding frame, wherein the two welding guns are provided with wire feeding mechanisms and welding power supplies respectively. The control system is located on the left side of the welding fixture, and the two welding power supplies are connected with the control system. The welding fixture comprises a welding front-rear symmetric supporting device, a lower supporting device, a supporting mandrel, a pneumatic key pressing device and a precision movement sliding rail. According to the welding device, a double metal compound pipe longitudinal joint with a diameter of 200-500 mm, a length of 1800 mm and a thickness of 4-7 mm can be clamped quickly and reliably, the control system can finish welding device control, welding track planning, welding parameter setting and welding process monitoring, and the double metal compound pipe longitudinal joint is automatically welded.

Owner:JIANGSU JIANGHAI MACHINE TOOLS GROUP

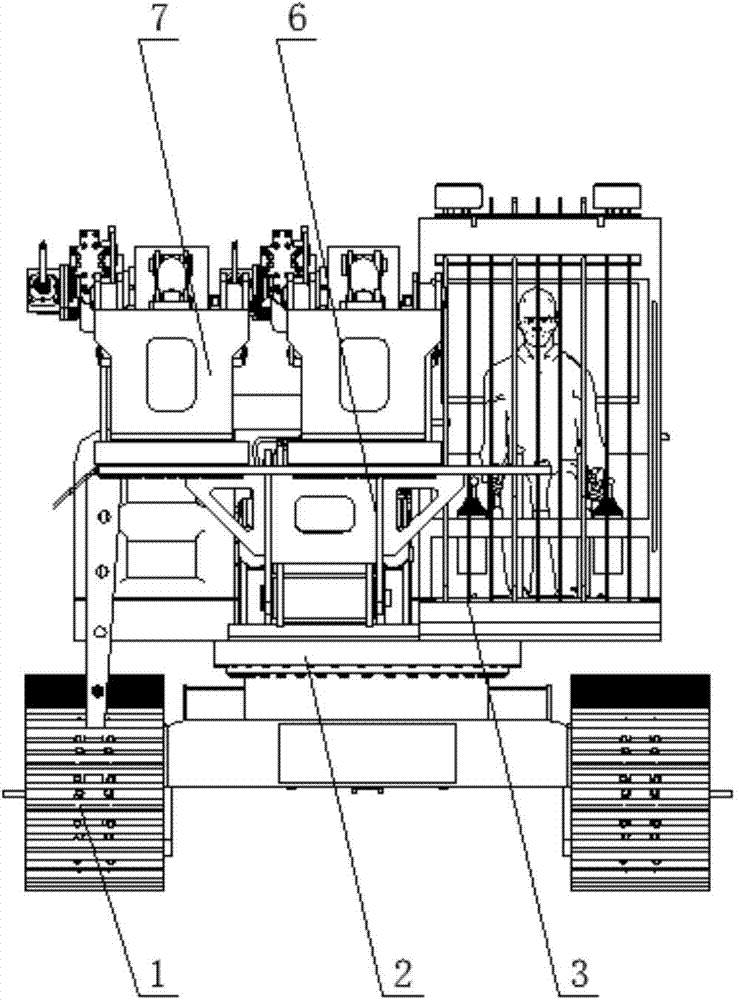

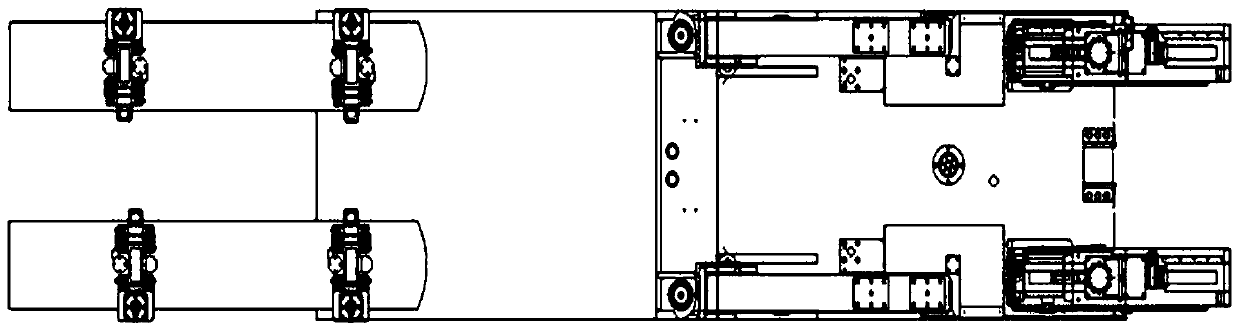

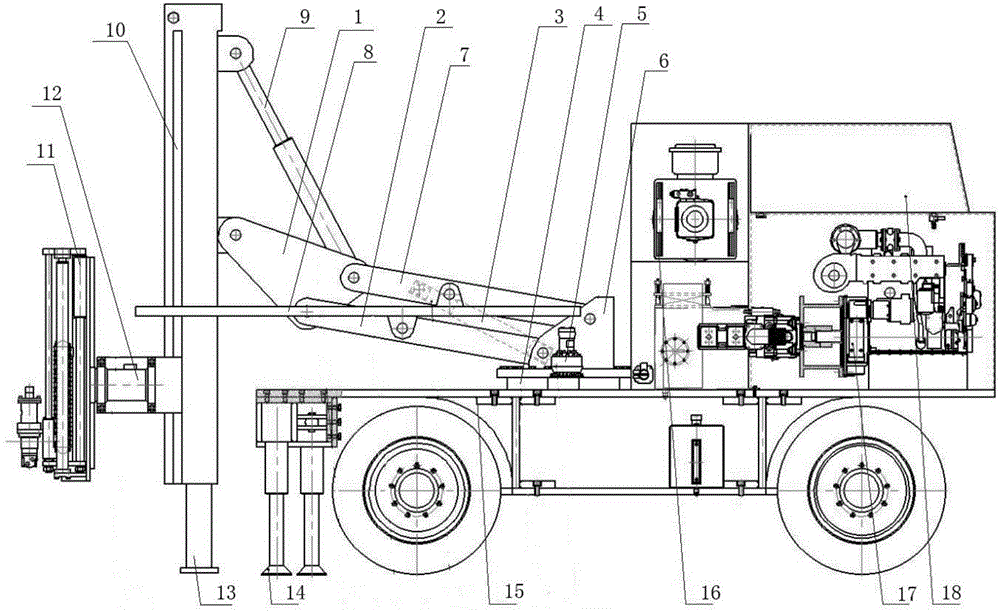

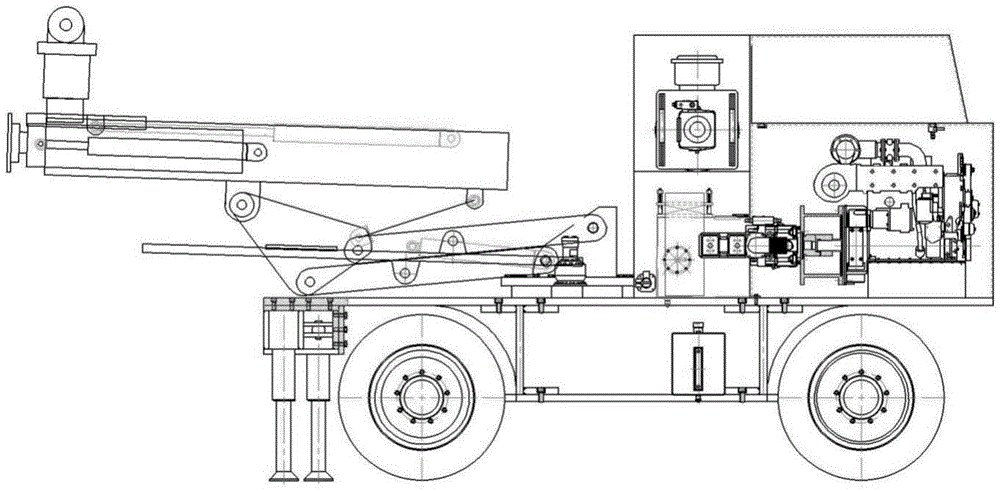

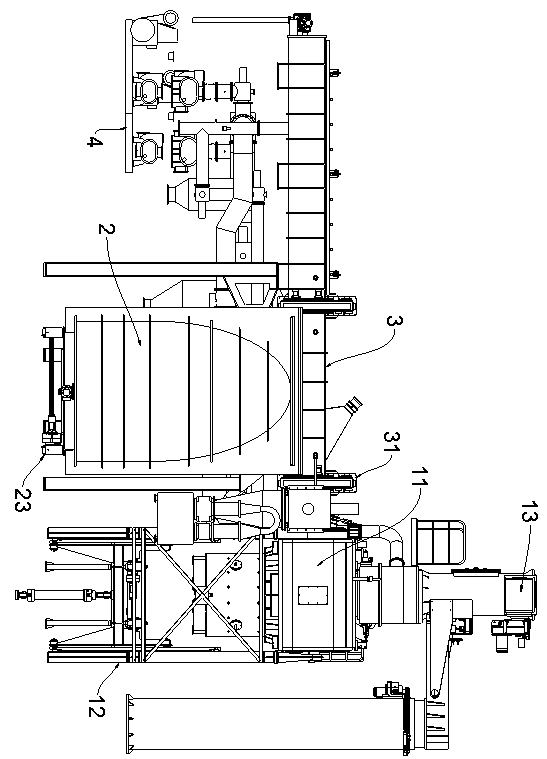

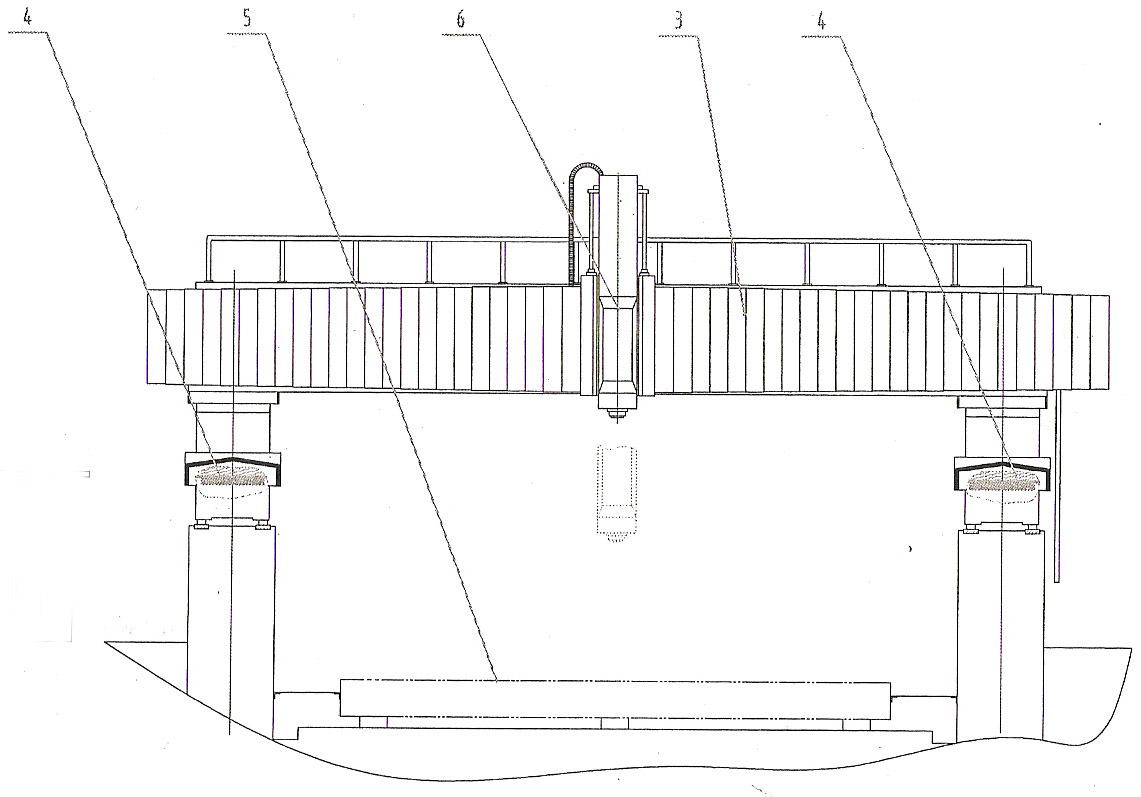

Narrow-fuselage six-arm fully hydraulic anchor rod anchor cable drill carriage

InactiveCN104196443ARealize the mechanization of working face supportImprove support efficiencyDerricks/mastsAnchoring boltsRock boltFuselage

The invention provides a narrow-fuselage six-arm fully hydraulic anchor rod anchor cable drill carriage which is composed of a walking mechanism, a lifting mechanism, a temporary support mechanism, a drilling arm mechanism, a pump station part, an electrical system and a hydraulic system. According to the narrow-fuselage six-arm fully hydraulic anchor rod anchor cable drill carriage, two rotating workbenches are arranged in front of a machine body, and each rotating workbench is provided with two drilling arms which rotate by 90 degrees through the rotating workbenches, the drill carriage is folded to make the narrow fuselage state be only 1.4 m, passing of the drill carriage and an integrated extractor in a roadway is achieved, the drill carriage can be unfolded by 5 meters when reaching a roadway head-on, four front drilling arms mainly hit a top anchor rod, two rear drilling arms mainly hit a top anchor cable and a side anchor rod, the six drilling arms work simultaneously, rapid anchor protection of the roadway can be realized, support efficiency can be greatly improved, tunneling footage is greatly improved, the coal extraction imbalance contradiction is better solved, and safe, efficient and benign development of coal production is promoted.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

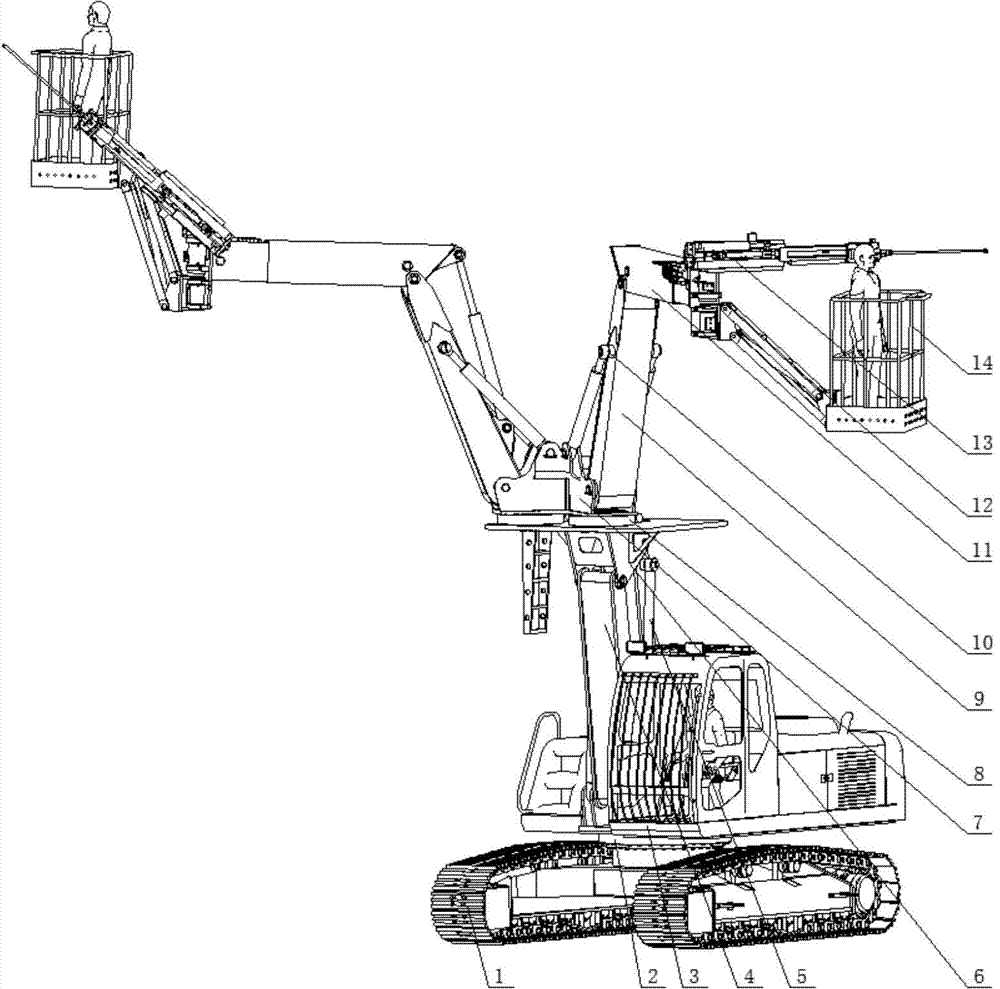

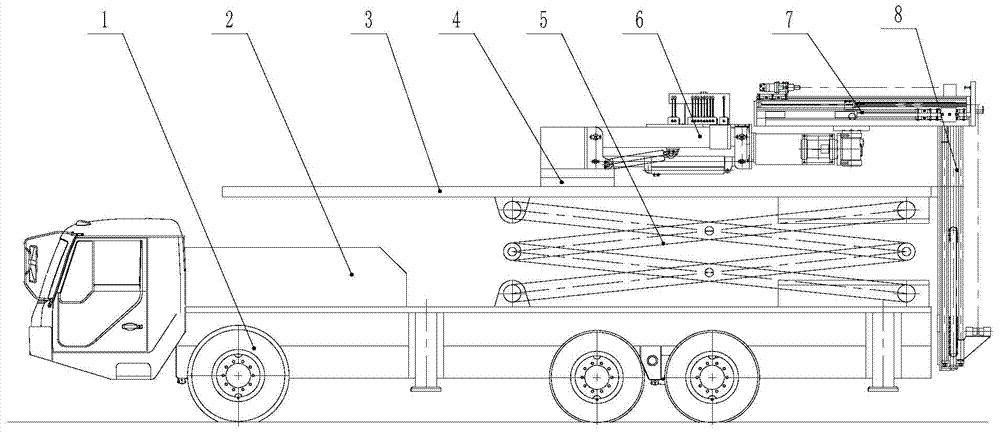

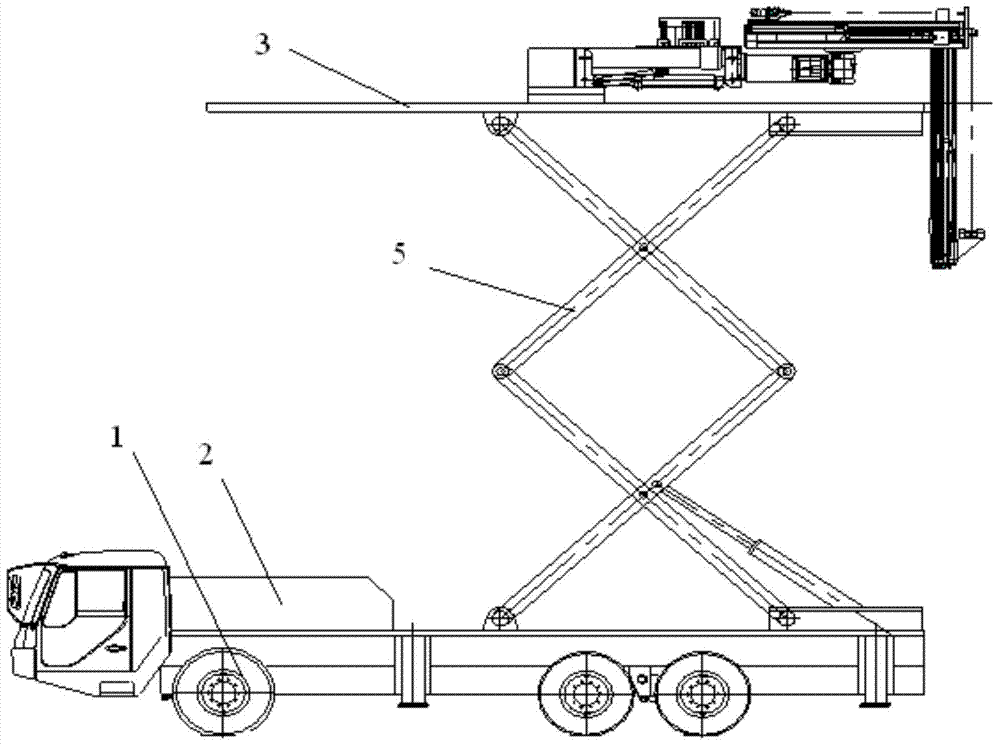

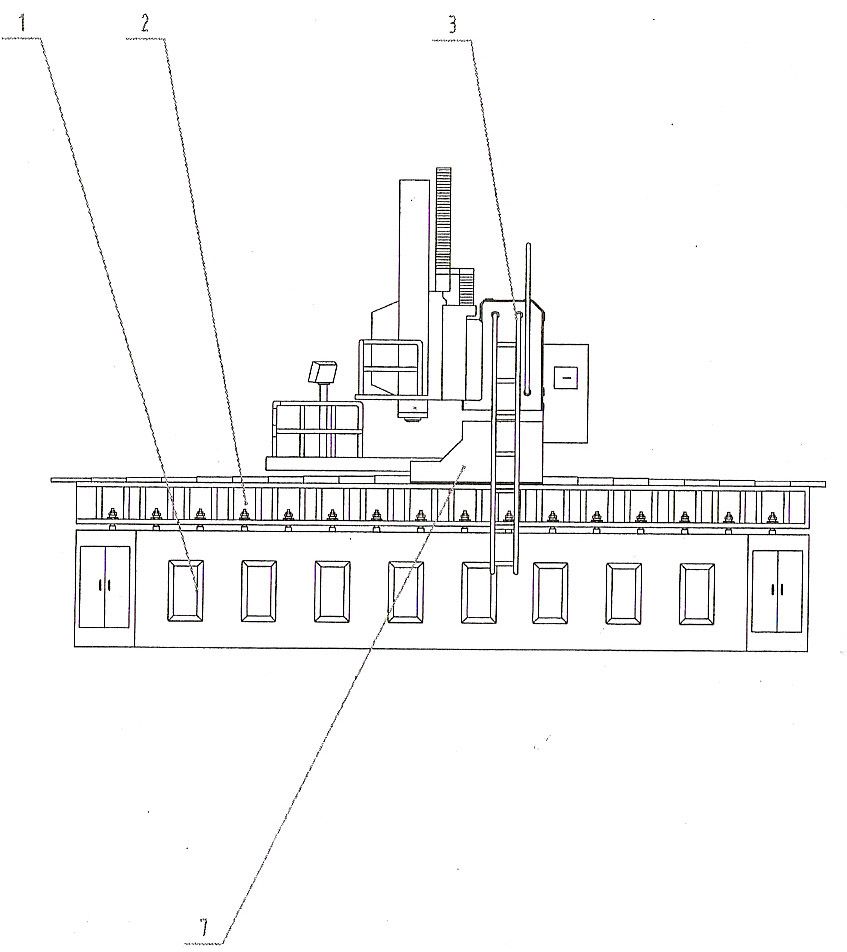

Tunnel construction trolley

ActiveCN104747078AMeet construction requirementsSolve construction difficultiesDerricks/mastsAnchoring boltsArchitectural engineeringDrill

The invention discloses a tunnel construction trolley. The tunnel construction trolley comprises a walking mechanism, a lifting platform, a drill arm mechanism, a lifting mechanism and a power and control device, wherein the walking mechanism is located on the bottom of a trolley body, and the power and control device is installed on the walking mechanism; the lifting platform is arranged above the walking mechanism in a liftable mode; the drill arm mechanism and the lifting mechanism are both installed on the lifting platform; the power and control device controls the lifting platform, the drill arm mechanism and the lifting mechanism to act. According to the tunnel construction trolley, anchor protection and lifting are integrated, not only can the construction requirement for the inland tunnel anchor bolt support be met, but also the mechanization and the automation of large section tunnel anchor bolt support work are achieved, the labor intensity is relieved, the efficiency is improved, and a better guarantee of the tunnel engineering quality is achieved.

Owner:蒲长晏

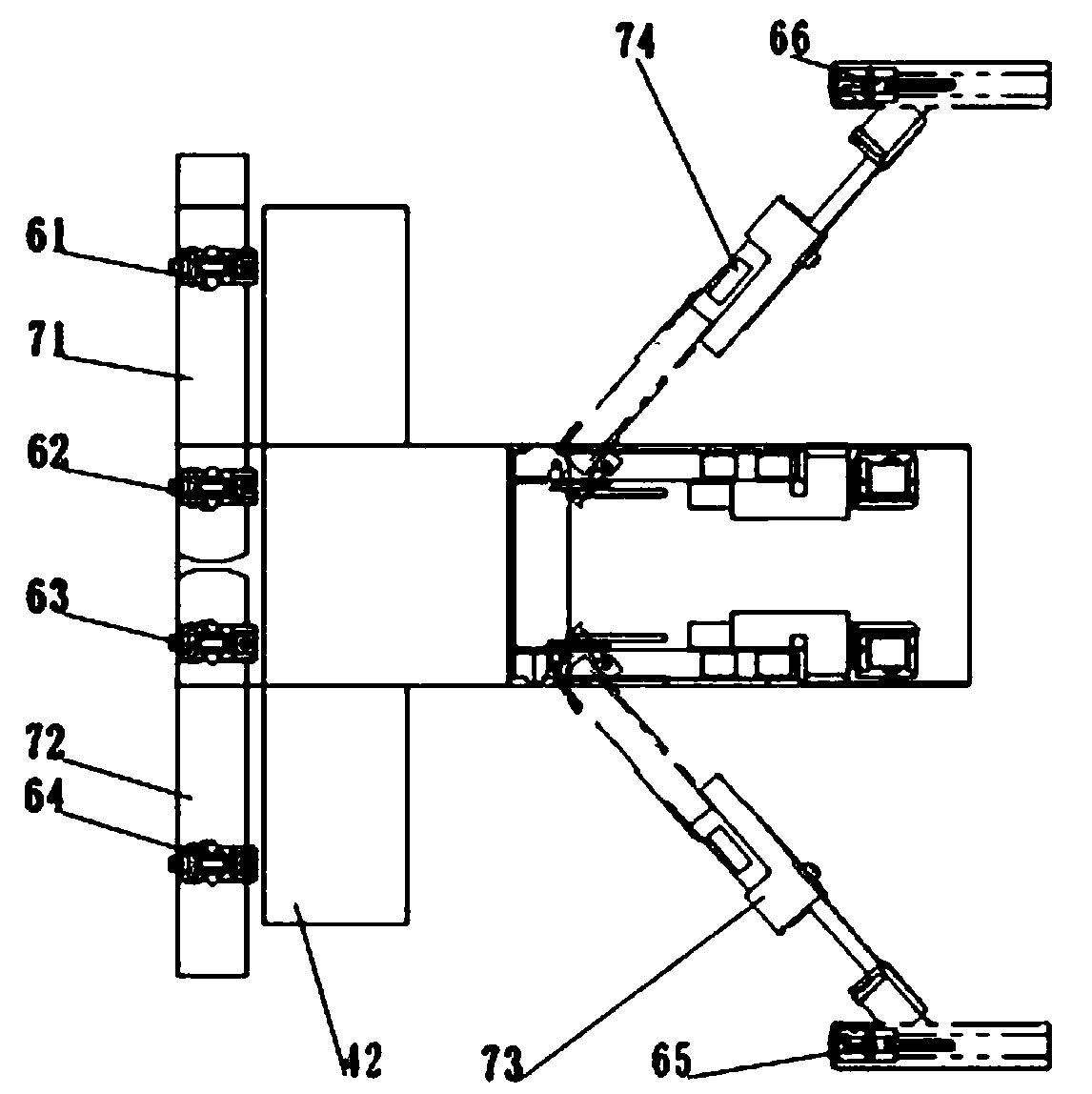

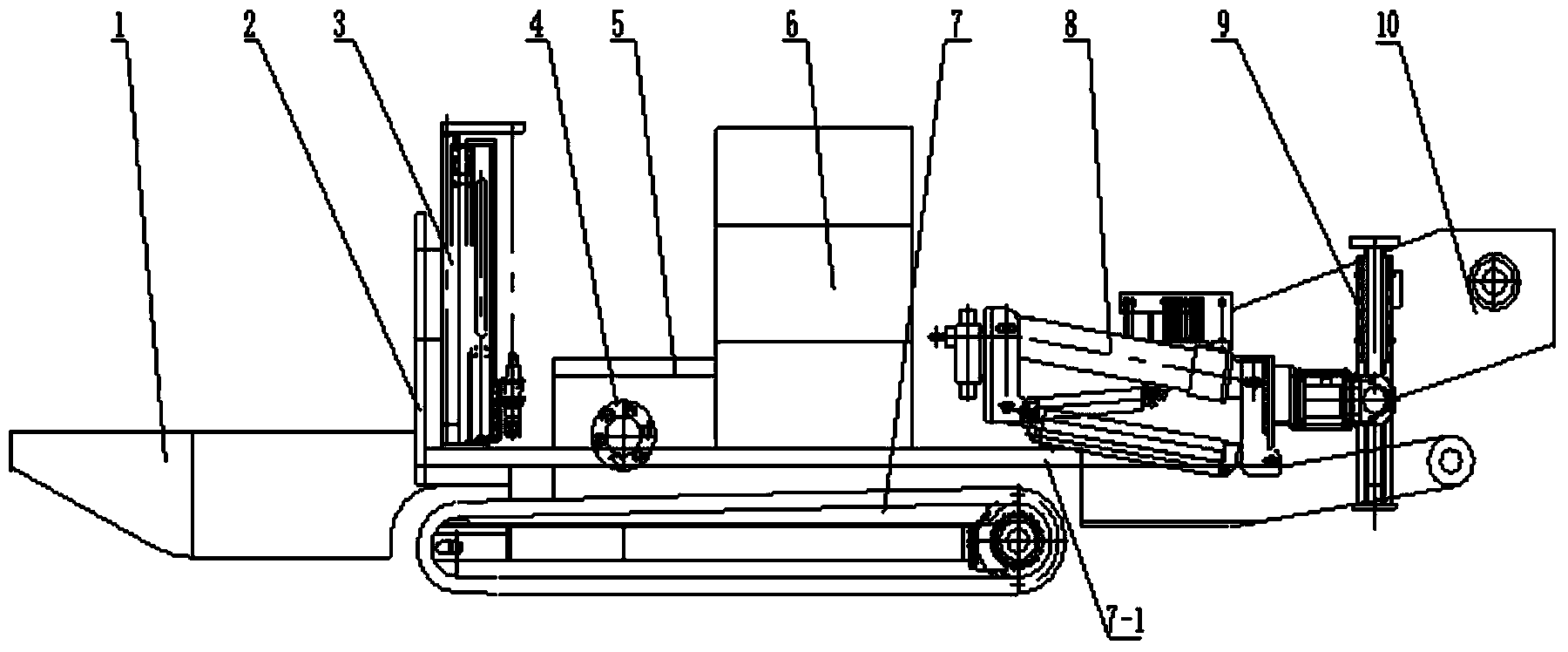

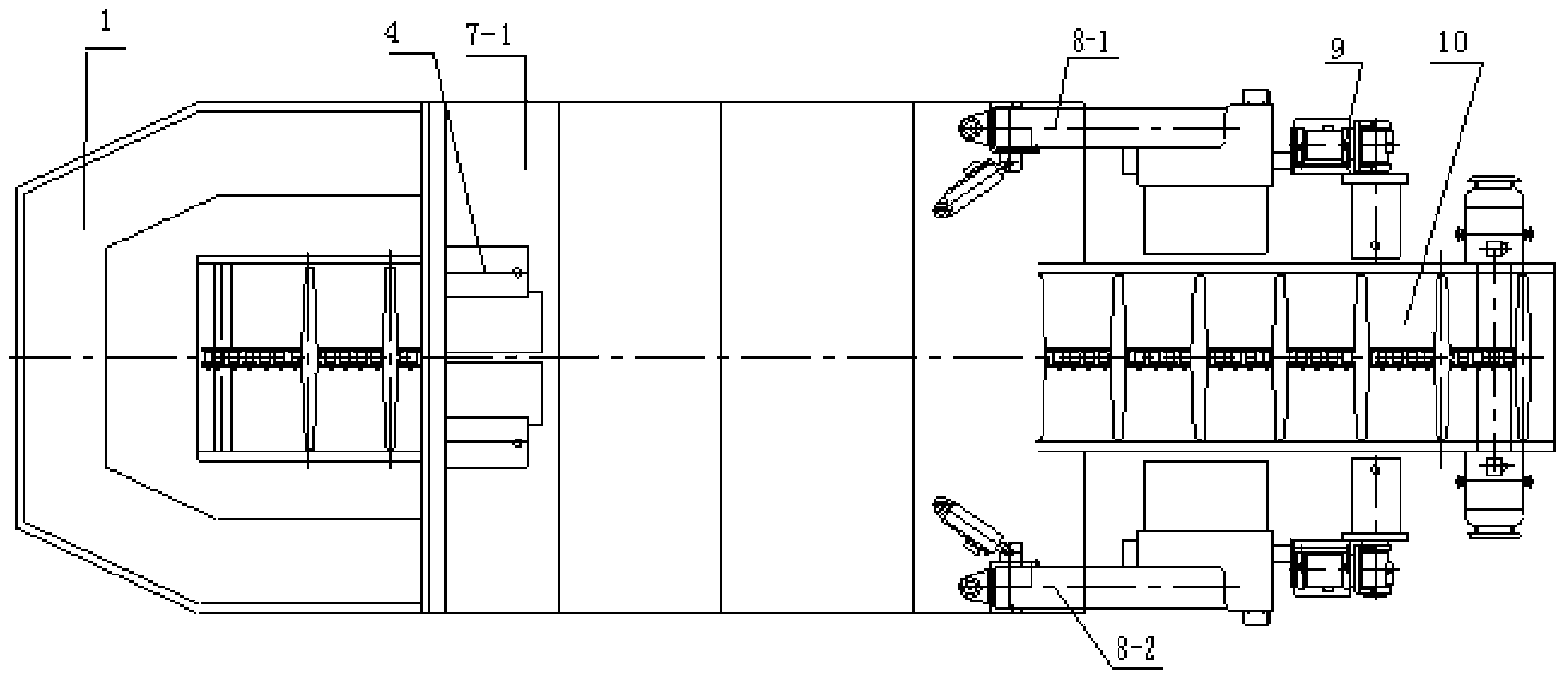

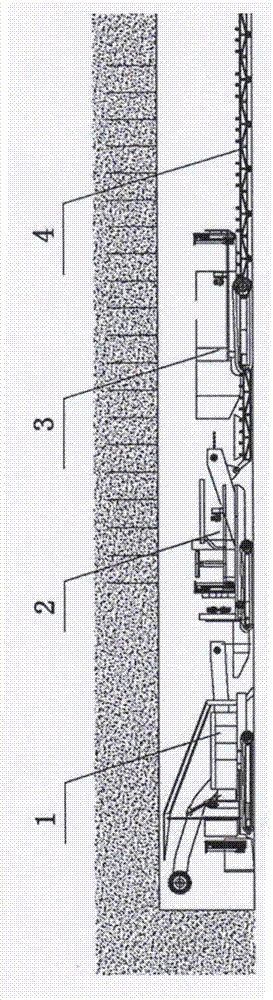

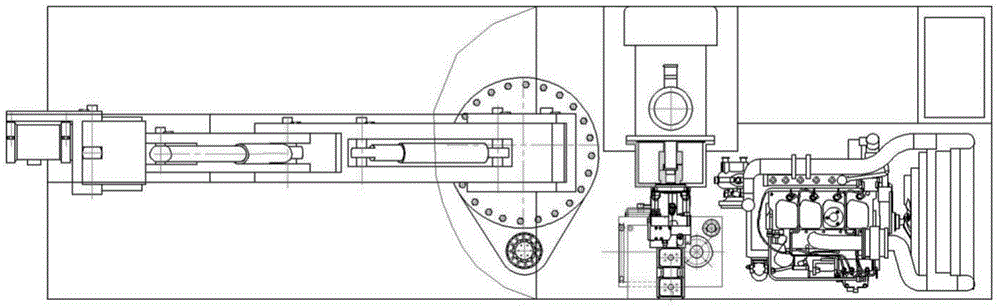

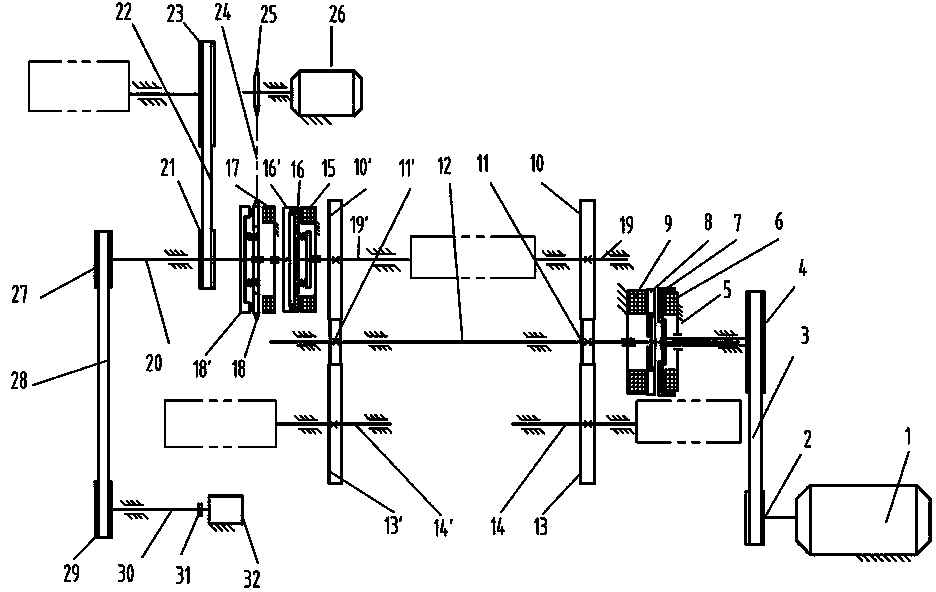

Transshipment anchor rod and anchor cable drill carriage

InactiveCN104265167ARealize mechanized supporting operationsSafe and reliable working conditionsSlitting machinesAnchoring boltsRock boltDrill

The invention discloses a transshipment anchor rod and anchor cable drill carriage which comprises a self-walking mechanism, a transshipment mechanism and a support mechanism. The self-walking mechanism is located at the bottom of the drill carriage, and an installation platform is arranged on the upper portion of the self-walking mechanism. The transshipment mechanism comprises a hopper and a transportation chute. The support mechanism comprises an anchor rod and anchor cable ejection drill rig, a slide for installation of the anchor rod and anchor cable ejection drill rig, an anchor rod and anchor cable assisting drill rig and a drill boom mechanism. The slide is installed on the installation platform in the direction perpendicular to the axial direction of the drill carriage and can stretch and draw back horizontally, and the anchor rod and anchor cable ejection drill rig can slide on the slide. The bottom end of the drill boom mechanism is installed on the installation platform, and the anchor rod and anchor cable assisting drill rig is installed at the top end of the drill boom mechanism. The support mechanism can conduct unfolding, contracting and supporting operations under the effect of an electric and hydraulic system. The transshipment anchor rod and anchor cable drill carriage integrates functions of material transshipment, material crushing and anchor rod and anchor cable supporting, achieves mechanical associated operating of the digging and anchoring work surface, conducts digging and anchoring simultaneously, and therefore greatly improves the digging efficiency and the digging footage and effectively solve the contradiction of digging imbalance.

Owner:蒲长晏

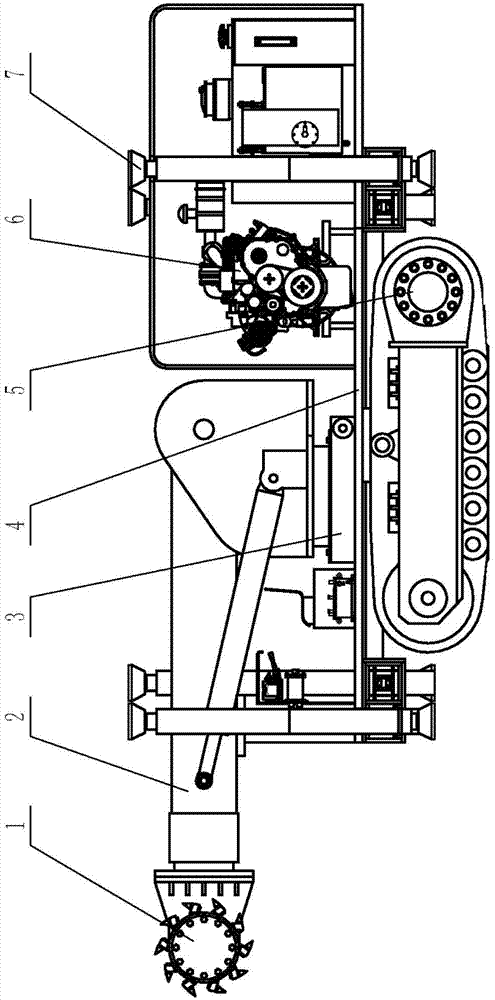

Grooving machine

The invention discloses a grooving machine, which comprises a self-walking mechanism, a working arm rotating mechanism, a working arm mechanism, a cutting mechanism, and a power and control mechanism, wherein the self-walking mechanism is arranged at the bottom of the grooving machine; a mounting platform is arranged at the upper part of the self-walking mechanism; the working arm rotating mechanism and the power and control mechanism are arranged on the mounting platform; the working arm rotating mechanism comprises a turbo-worm reducer and a working arm mounting holder connected with an output shaft of the turbo-worm reducer; the turbo-worm reducer is fixed on the mounting platform; the working arm mechanism is rotatably connected onto the working arm mounting holder and is connected with the cutting mechanism; the power and control mechanism is connected with and controls actions of the self-walking mechanism, the working arm mechanism, the working arm rotating mechanism and the cutting mechanism. A grooving working arm can rotate freely for 360 degrees; the stability coefficient of the grooving machine can be increased through an expendable stabilizing support leg mechanism; the mechanical grooving operation is realized; the grooving efficiency is improved; the labor intensity is alleviated and the safety coefficient is increased.

Owner:蒲长晏

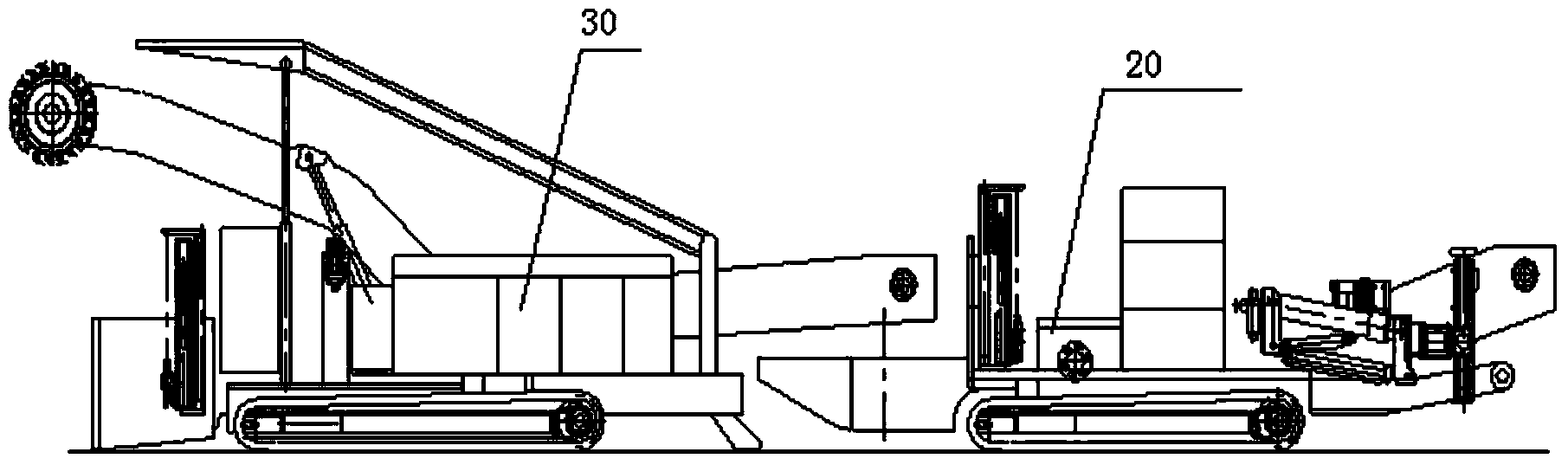

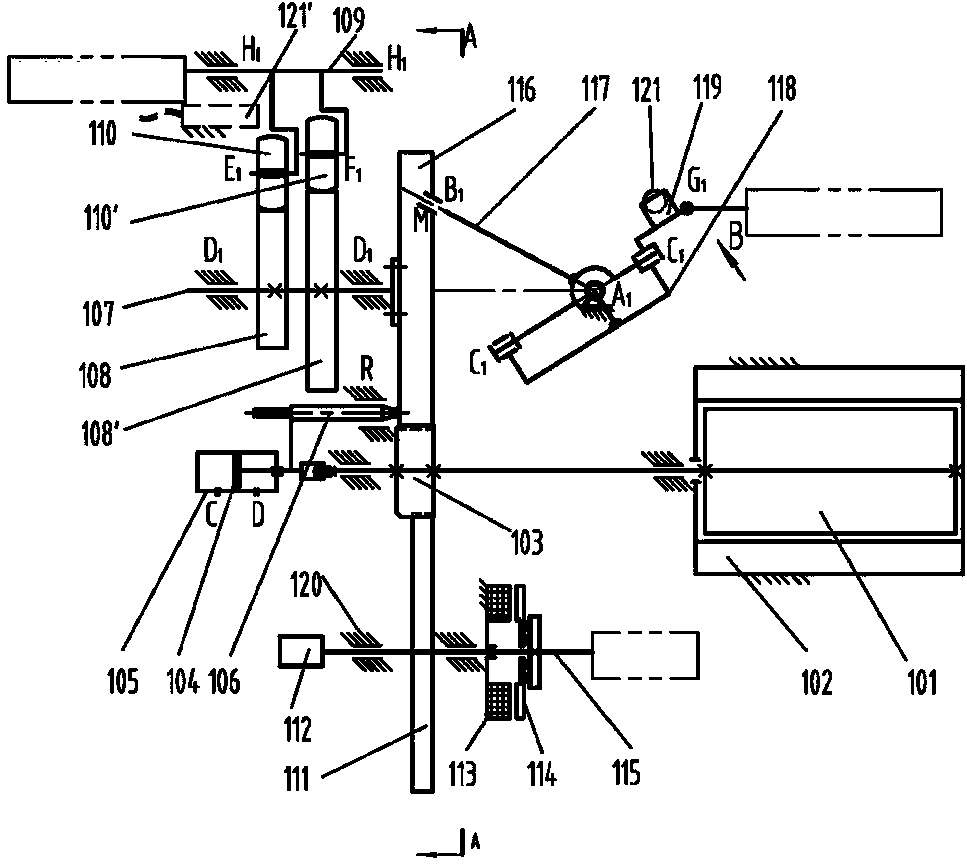

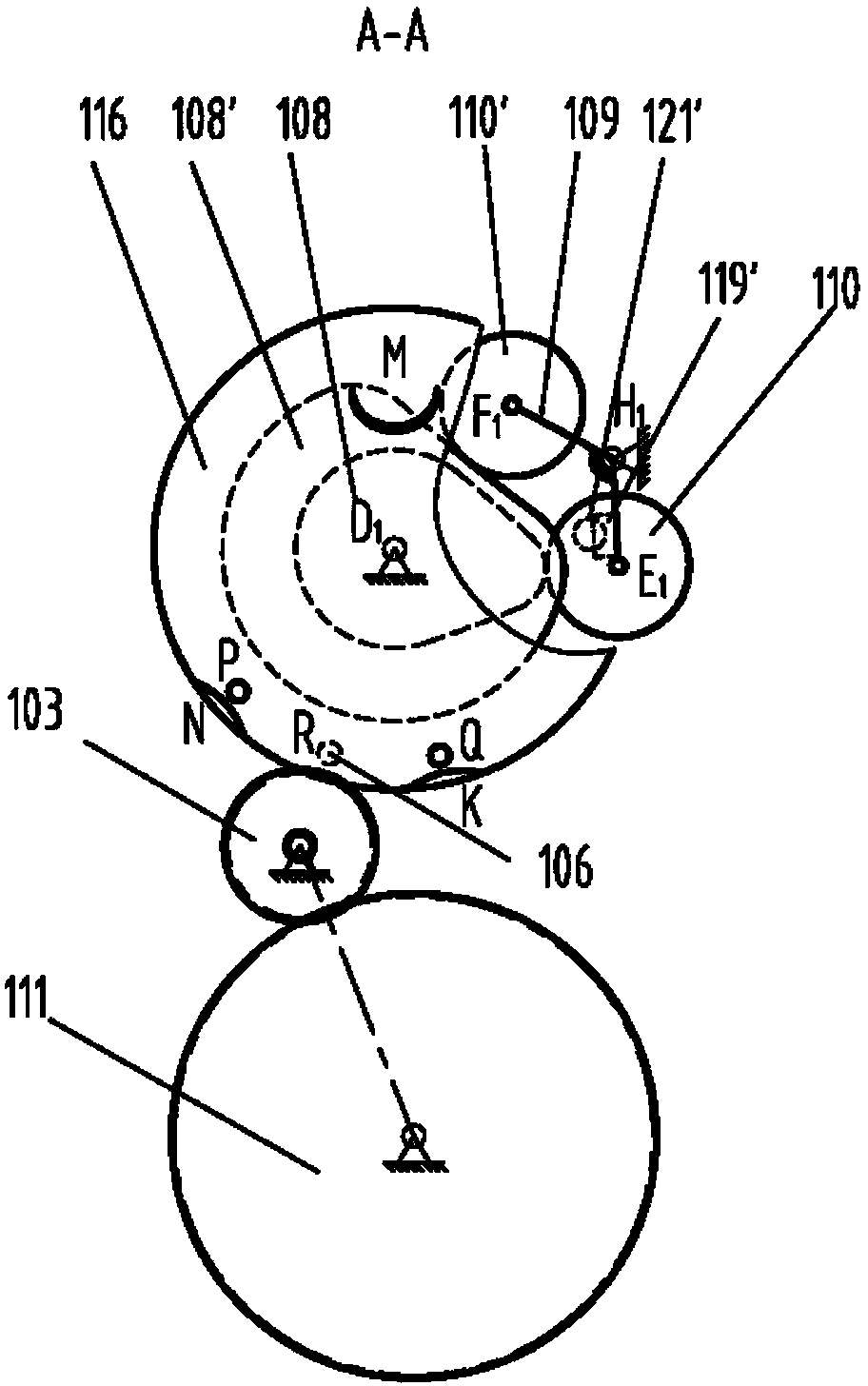

Transferring and anchor rod anchor cable supporting system

ActiveCN104763452AReduce manual labor intensityImprove bolting efficiencyUnderground transportAnchoring boltsEngineeringLeather belt

The invention discloses a transferring and anchor rod anchor cable supporting system. The transferring and anchor rod anchor cable supporting system comprises a supporting head vehicle, a supporting back vehicle, a transferring belt and a power and control device. The supporting head vehicle and the supporting back vehicle are flexibly connected. The back end of the supporting head vehicle is connected with the front end of the transferring belt. The supporting back vehicle bestrides the transferring belt. The power and control device is arranged on the supporting back vehicle to provide power for the supporting head vehicle and the supporting back vehicle and control the action of the supporting head vehicle and the action of the supporting back vehicle. The transferring and anchor rod anchor cable supporting system is used in cooperation with speedy heading equipment, mechanized construction of a roadway full fracture surface support can be completed at a time, full-automatic operation of an anchor rod support is achieved, the labor intensity of workers is greatly reduced, the anchor rod supporting efficiency is improved, and the problem of mining maladjustment is solved fundamentally.

Owner:蒲长晏

Straw smashing and briquetting all-in-one machine

PendingCN107455104AGuaranteed continuityAvoid cloggingCuttersShaping pressProcess engineeringMachine

The invention discloses a straw smashing and briquetting all-in-one machine. The machine includes a base, idler wheels, a discharging pipe, a cutting device, a pressing platform and a pressing plate. According to the straw smashing and briquetting all-in-one machine, the two processes of smashing and briquetting the straw are combined together to ensure continuity of work; the smashing device is reasonable in mechanism and can effectively prevent the straw from entwining in a conveying passage and forming a blockage, and ensure the overall working efficiency; through arrangement of a cover plate capable of moving along with the pressing plate, smashing and briquetting of the straw can be conducted at the same time without causing interference to each other, so that the working efficiency is improved; when the pressing plate conducts briquetting on the straw, water inside the straw is filtered by a filtering plate and falls down along filtering holes, so that the situation is avoided that because an excessive amount of water is extruded during extrusion, the process of extrusion is intervened, and meanwhile, the briquetting effect is ensured. The all-in-one machine is also provided with the idler wheels adjustable in height, and therefore the overall machine can move conveniently, and the idler wheels are stored during work, so that the stability of the overall machine during running is ensured.

Owner:ZHENGZHOU UNIV

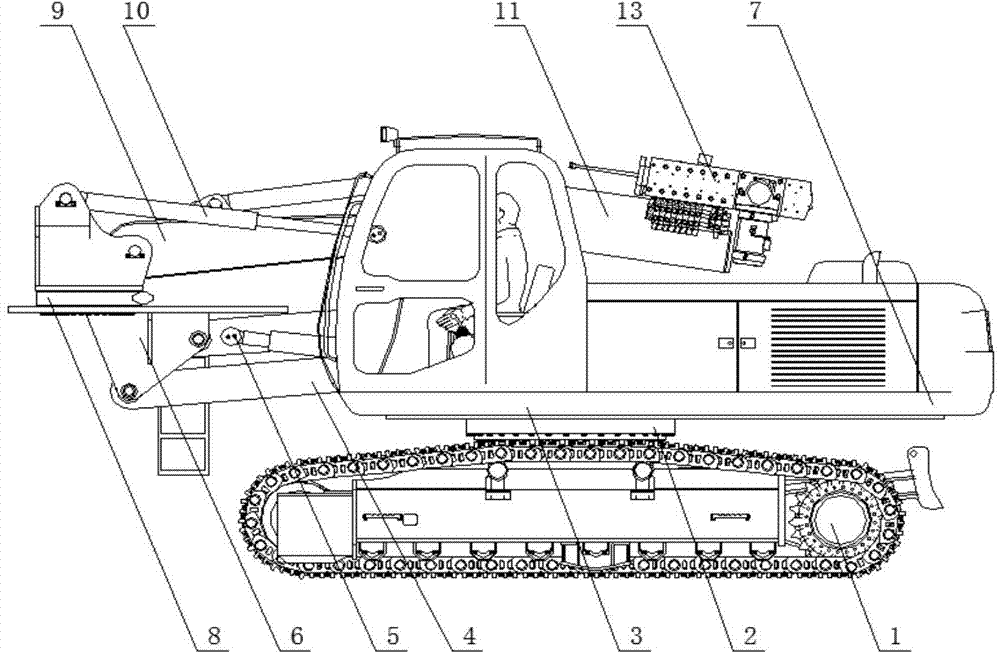

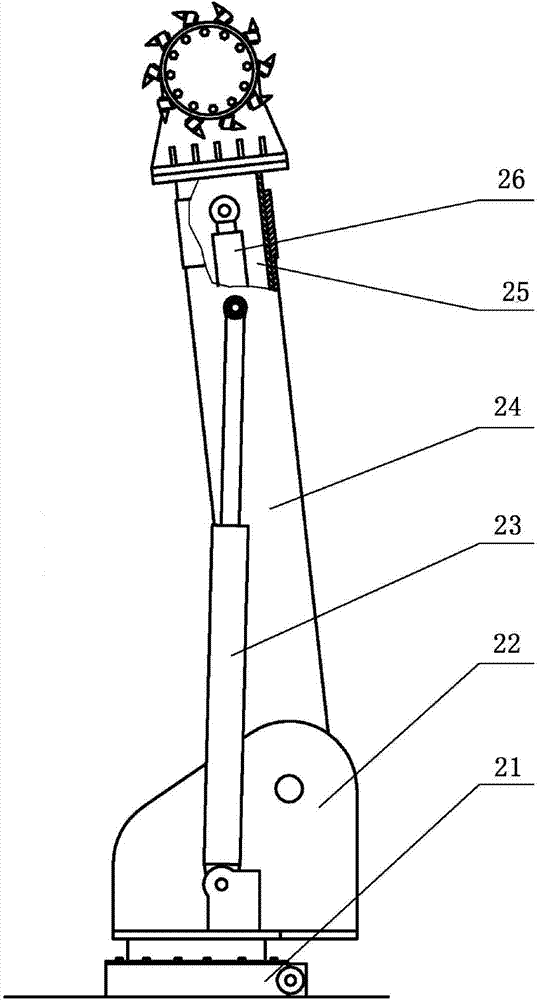

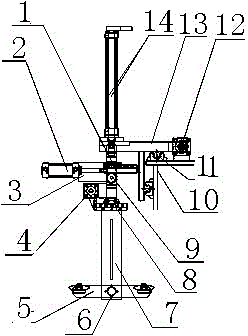

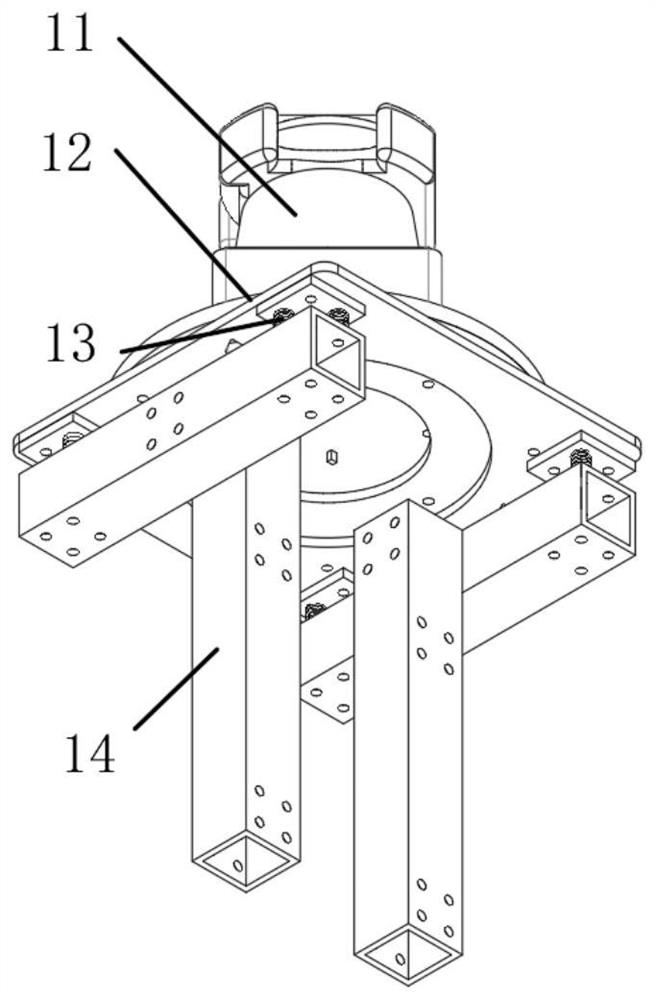

Pre-embedded hole drill carriage for coal mine

InactiveCN104818945AEasy to operateLow failure rateDerricks/mastsDrilling machines and methodsEngineeringPre embedding

The invention discloses a pre-embedded hole drill carriage for coal mine. The pre-embedded hole drill carriage for the coal mine comprises a drilling mechanism, a traveling chassis and a driving control part, the driving control part is arranged at the front of the traveling chassis, and the drilling mechanism comprises a rotating device arranged above the middle of the traveling chassis, a lifting device arranged on the rotating device, and a drilling device arranged on the lifting device in a sliding mode. The pre-embedded hole drill carriage for the coal mine is reasonable in structure design, good in rigidity, free in traveling, reliable, capable of working under a hostile environment, narrow, convenient to give another the right of way in a narrow coal mine roadway, and capable of realizing the safe, effective and mechanical working targets of the pre-embedded hole construction of the coal mine of China, and the pre-embedded hole drill carriage is a very ideal pre-embedded hole construction device.

Owner:蒲长晏

Movable lamp

InactiveCN103133952AIngenious ideaReasonable organizationLighting support devicesFixed installationLight fixtureEngineering

Owner:邵健

Earthing device for transplantation of potted flowers

ActiveCN103222399AReasonable organizationEasy to install and maintainFlower-pot fillingWater pipeEngineering

The invention discloses an earthing device for transplantation of potted flowers. A support frame supports the whole earthing device, a reflection sensor is mounted on a baffle, a hopper support is mounted on the support frame, an earthing cover is fixed on the outer side of the hopper support, the baffle is fixed on the hopper support in a centralized manner, wedges are fixed on the baffle in an equally spaced manner, a water pipe sequentially penetrates the wedges through a slot in the baffle, two guide rails are symmetrically mounted on the hopper support and matched with slide blocks mounted at the lower part of a material bin, two rotating shafts are mounted on the hopper support, a cog belt is matched with the rotating shafts, a stepping motor is coupled with the rotating shafts through a coupler, and a protective shell is fixed on the outer sides of the cog belt, the stepping motor and the rotating shafts and fixed with the hopper support. After a flowerpot is transmitted to a certain position, the stepping motor drives the material bin to earth the interior of the flowerpot, and as the wedges are provided, a cavity shaped like a small flowerpot is formed in the flowerpot to facilitate transplanting potted flowers.

Owner:曹伟鹏 +1

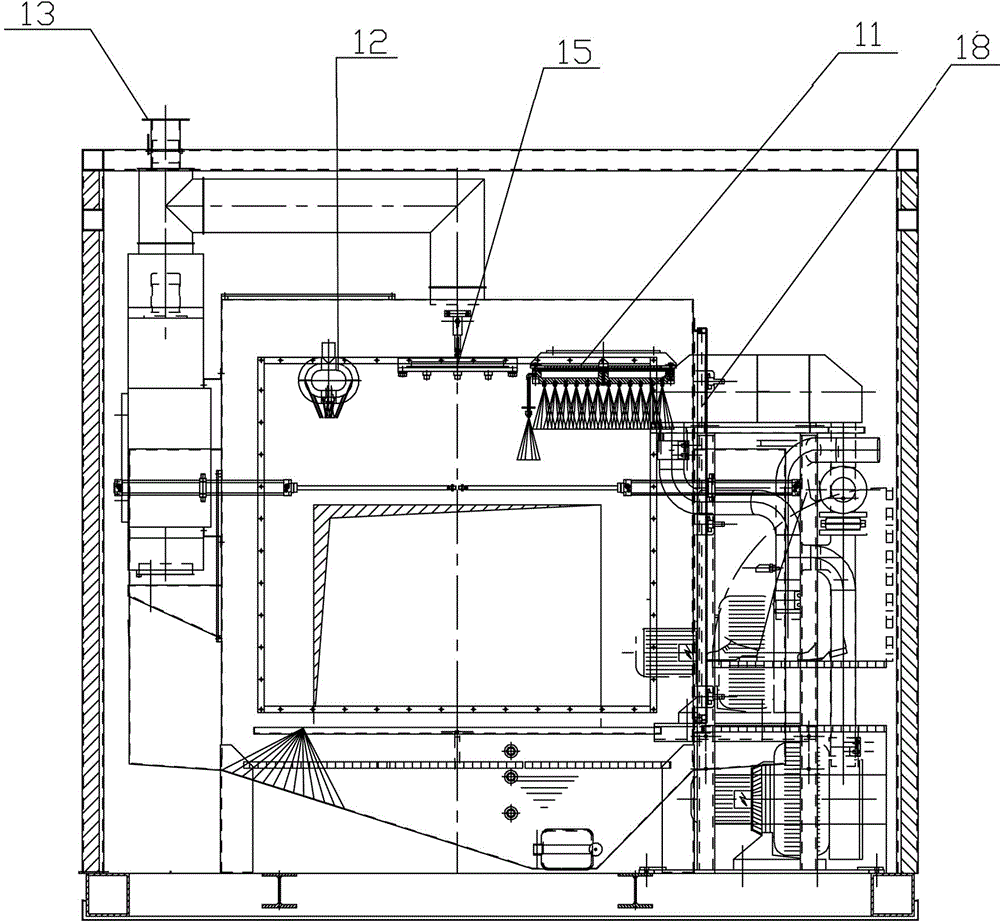

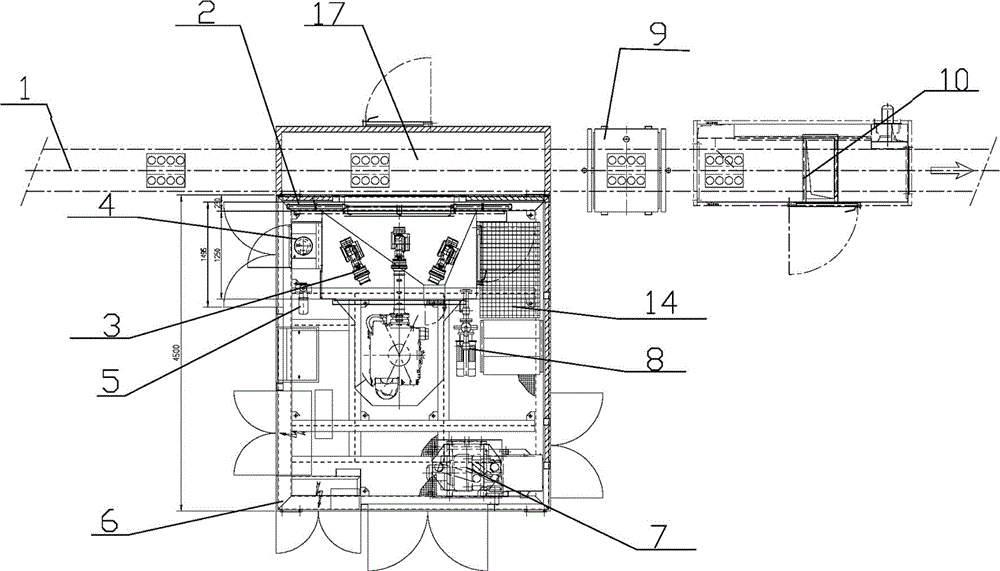

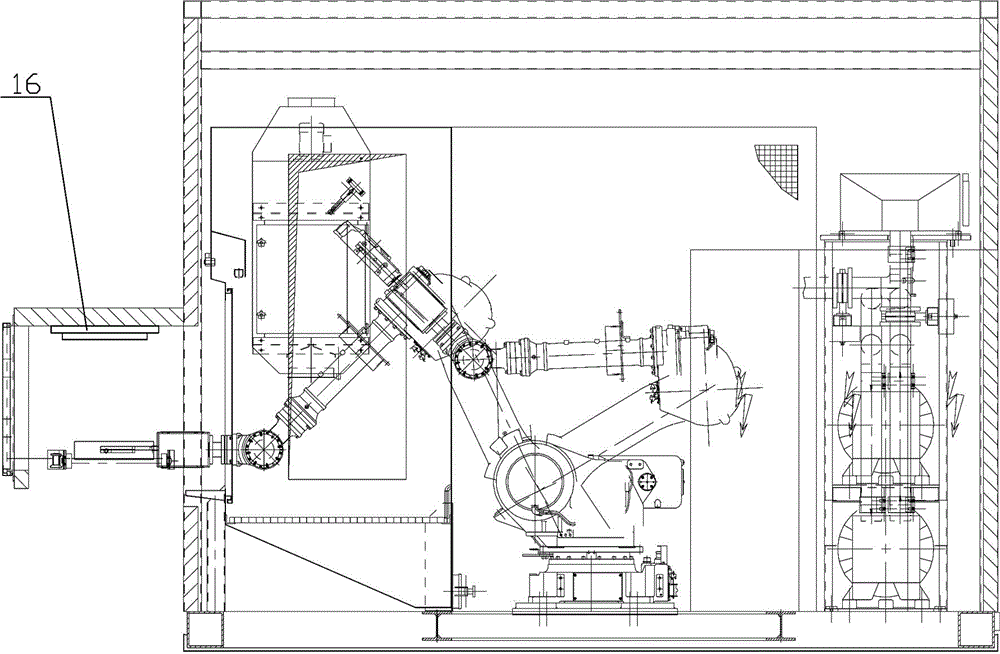

Intelligent robot flexible online cleaning machine

InactiveCN104646335AInformation managementReasonable organizationDrying solid materials without heatDrying gas arrangementsAir compressionEngineering

An intelligent robot flexible online cleaning machine comprises a transportation guide rail, a cylinder sliding door, a feeding area, a visual identification system, a six-axis linkage cleaning robot, a water pump, an electric control cabinet, an air compression system, an air exhaust pipeline, a high-pressure cleaning unit, a spray cleaning unit, a compressed air blowing-dry unit, a vacuum drying unit and a cooling unit. The intelligent robot flexibility online cleaning machine is reasonable in mechanism, high in cleaning efficiency and low in energy consumption, continuous cleaning is realized through the robot, device running information can be uploaded to a superior computer system, and the requirement of workshop logistics information management is met.

Owner:YICHANG WASHING MACHINE +1

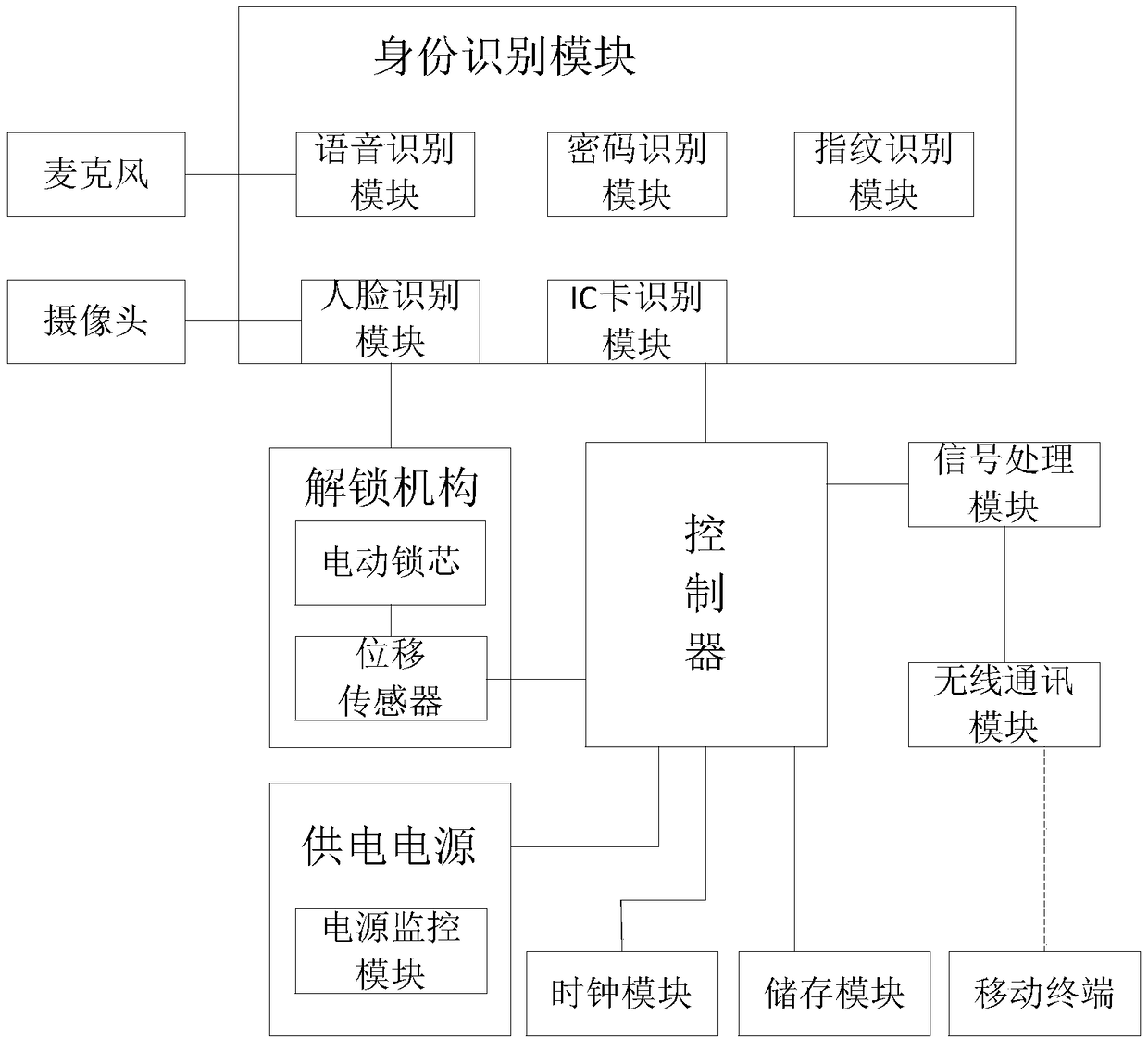

Lock control apparatus for substation

InactiveCN109064594AThe overall organization is reasonableEasy to make and implementIndividual entry/exit registersMicrophoneSpeech recognition

The invention provides a lock control apparatus for a substation, comprising a controller. The controller is electrically connected with an identity recognition module, an unlocking mechanism, a powersupply, a clock module, a storing module and a signal processing module, wherein the signal processing module is electrically connected with a wireless communication module. The identity recognitionmodule is electrically connected with the unlocking mechanism, the identity recognition module comprises a voice recognition module, a password recognition module, a fingerprint recognition module, aface recognition module and an IC card recognition module, wherein the voice recognition module is electrically connected with a microphone, the face recognition module is electrically connected witha camera. The unlocking mechanism comprises an electric lock cylinder and a displacement sensor, wherein the displacement sensor is electrically connected with the controller. The power supply comprises a power supply monitoring module. The lock control apparatus for the substation has the advantages of being convenient to operate, having multiple unlocking modes, being good in safety and high inefficiency.

Owner:JIANGSU HUAWEI ELECTRIC POWER TECH

Weaving machine transmission and weaving machine position automatic calibration system driven by switch reluctance motor

The invention provides a weaving machine transmission and weaving machine position automatic calibration system driven by a switch reluctance motor. A motor stator of the switch reluctance motor is fixedly arranged on a machine frame, the motor rotor is fixedly connected with a main motor gear shaft supported on the machine frame through a bearing, one end of the main motor gear shaft is connected with a piston through a bearing, and the piston is fixedly connected with a movable insertion pin arranged in a guide hole formed in the machine frame, so the insertion pin forms cylinder pair connection with the machine frame, the piston is arranged in a piston cylinder fixedly arranged on the machine frame, in addition, the cylinder pair connection is formed, the piston is matched with the insertion pin, and can transversely move but cannot rotate; the main motor gear shaft is engaged with an opening transmission gear fixedly connected onto an opening transmission shaft through a shaft gear, the opening transmission shaft is fixedly connected with an armature of an opening brake through a spring, the two ends of the opening transmission shaft are respectively connected with an encoder and an opening mechanism, and a coil of the opening brake is fixedly connected with the machine frame. The weaving machine transmission and weaving machine position automatic calibration system has the characteristics that the mechanism is reasonable, the use is convenient and reliable, the speed of a weaving machine can be accelerated, the speed change and position calibration automation degree of the weaving machine can be improved, and the like.

Owner:浙江万利纺织机械有限公司 +1

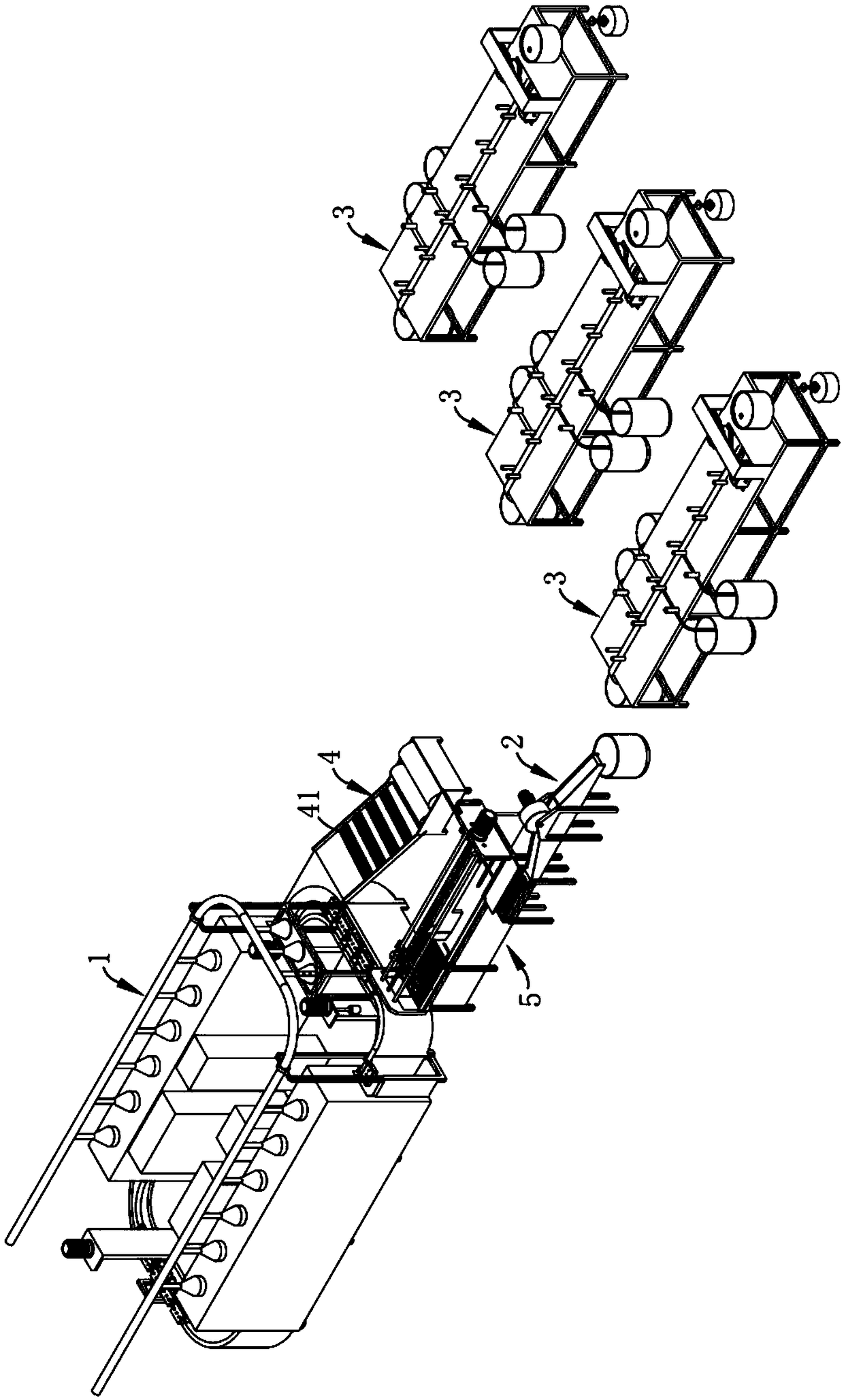

Continuous automatic production line for flax yarn

InactiveCN108950750AAutomate the connectionImprove reliabilityPiercing arrangementsContinuous processingState of artYarn

The invention relates to the technical field of flax yarn production, in particular to a continuous automatic production line for flax yarn. The production line comprises a raw material pretreatment device, a hackling machine, an automatic flax fiber material adding device, a drawing frame and a yarn mixing machine; the automatic flax fiber material adding device comprises a traction mechanism, asplitting mechanism and a material adding mechanism; a fiber bundle obtained after overlapping and winding is transferred into the drawing frame, a fiber rod is formed, and the fiber rod is made intorough yarn through the yarn mixing machine; by means of the traction mechanism, in the process of conducting directional transfer o the flax yarn, short fiber removing and fiber bundle separation areconducted on the flax yarn by cooperating with a carding mechanism and the splitting mechanism respectively, by combining the transmission connection characteristic of a lap joint mechanism and a driving mechanism, automatic winding in the end-to-end lapping process of the fiber bundle is achieved, high-quality automatic production of flax splitting and lapping is achieved, and the technical problem that in the prior art, due to the fact that manual splitting it not uniform, the yarn quality is not stable is solved.

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

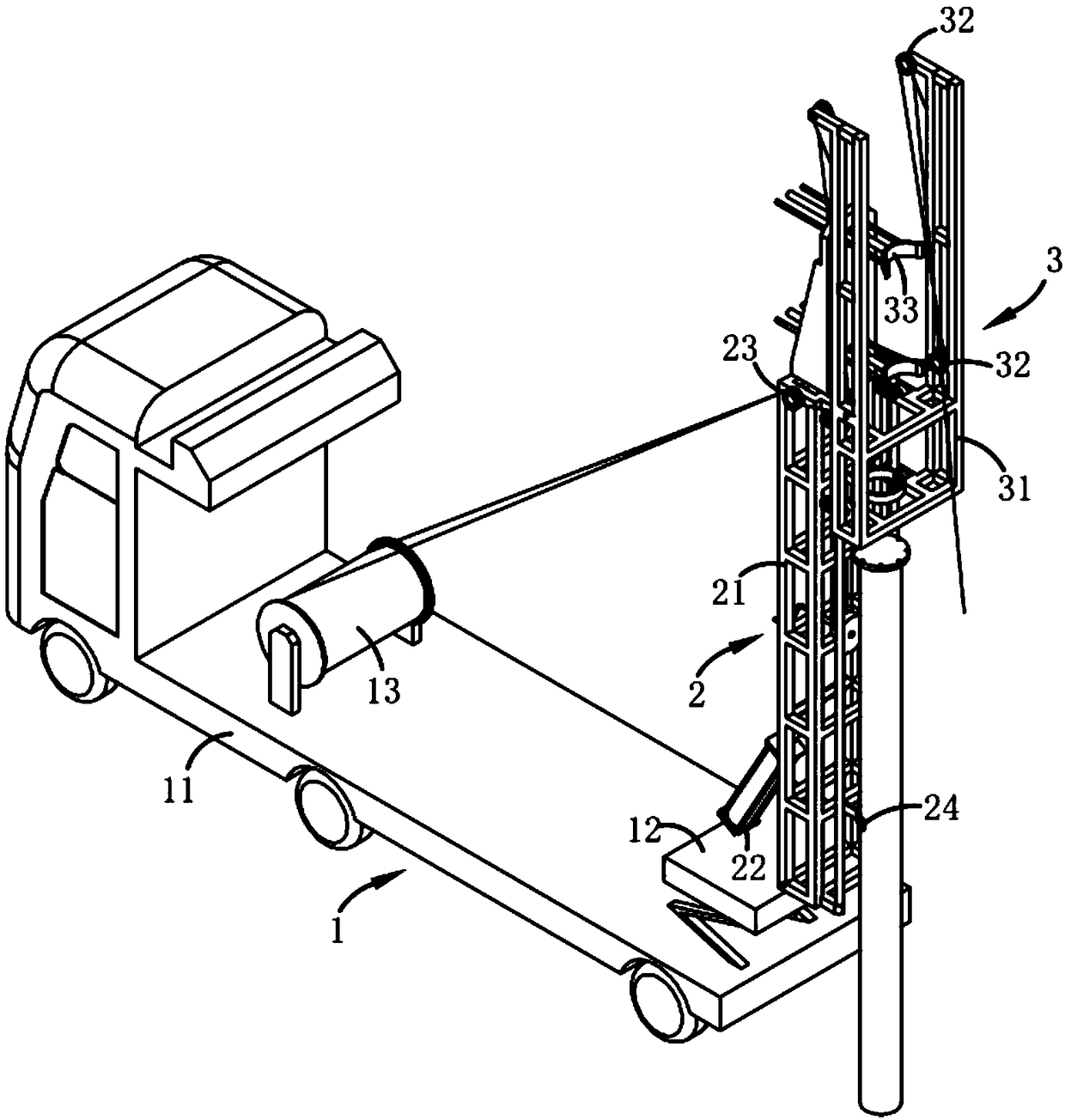

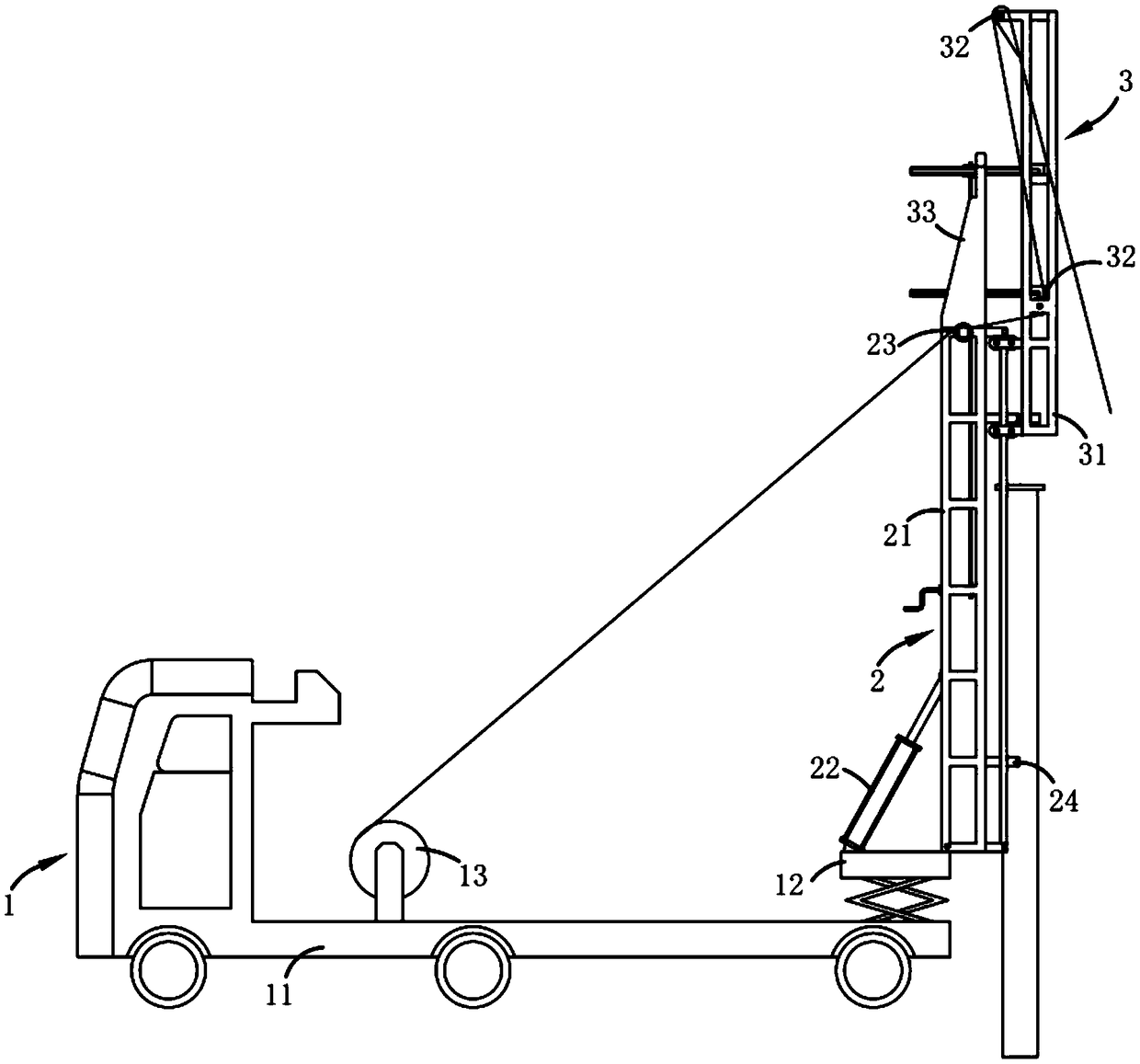

Multi-section cement pole automatic assembly and installation device

ActiveCN109083486AImprove assembly efficiencySolve complex technical problems in constructionTowersEngineeringMoving frame

The invention relates to the technical field of telegraph pole construction, in particular to a multi-section cement pole automatic assembly and installation device. The multi-section cement pole automatic assembly and installation device comprises a bearing mechanism, a primary lifting mechanism and a secondary lifting mechanism. The bearing mechanism comprises a transfer vehicle, a bearing platform and a dragging assembly. The primary lifting mechanism comprises a bracket, a drive assembly, a supporting assembly and a positioning assembly. The secondary lifting mechanism comprises a moving frame arranged on the bracket, a lifting assembly arranged on the moving frame, connected with the supporting assembly and used for lifting an auxiliary rod, and a translation assembly arranged on thebracket and used for positioning and transferring the auxiliary rod on the lifting assembly. Through the special structure arrangement of the primary lifting mechanism and the secondary lifting mechanism, a main rod and the auxiliary rod are constructed in sequence, the auxiliary rod is laterally dragged through the lifting assembly, the auxiliary rod is supported through the translation assembly,the auxiliary rod is lifted above the main rod and then stably and accurately subjected to translation, and the auxiliary rod and the main rod are rapidly assembled. The technical problem that in theprior art, a multi-section telegraph pole is complex in construction is solved.

Owner:临泉鹏成机电技术有限公司

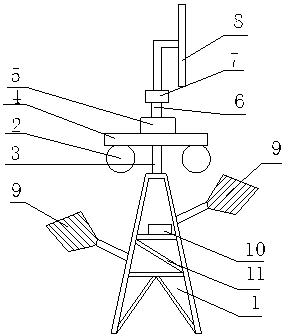

Improved wind energy solar energy beacon

InactiveCN102980122AEfficient use ofSave resourcesLighthouseElectric circuit arrangementsWind drivenCircular disc

The invention discloses an improved wind energy solar energy beacon which comprises a beacon body and illuminating lamps. The improved wind energy solar energy beacon is characterized in that a support frame is mounted on the top of the beacon body, a circular metal plate is arranged above the support frame, the illuminating lamps are arranged below the circular metal plate, a motor is arranged on the circular metal plate, a disk is arranged on a rotating shaft of the motor, a wind-driven generator is mounted on the disk, solar panels are disposed on the beacon body, a storage battery is also arranged on the beacon body, and the storage battery is connected with the illuminating lamps. The improved wind energy solar energy beacon has the advantages of being reasonable in structure and high in practicability, saving resources and protecting the environment.

Owner:宋小卫

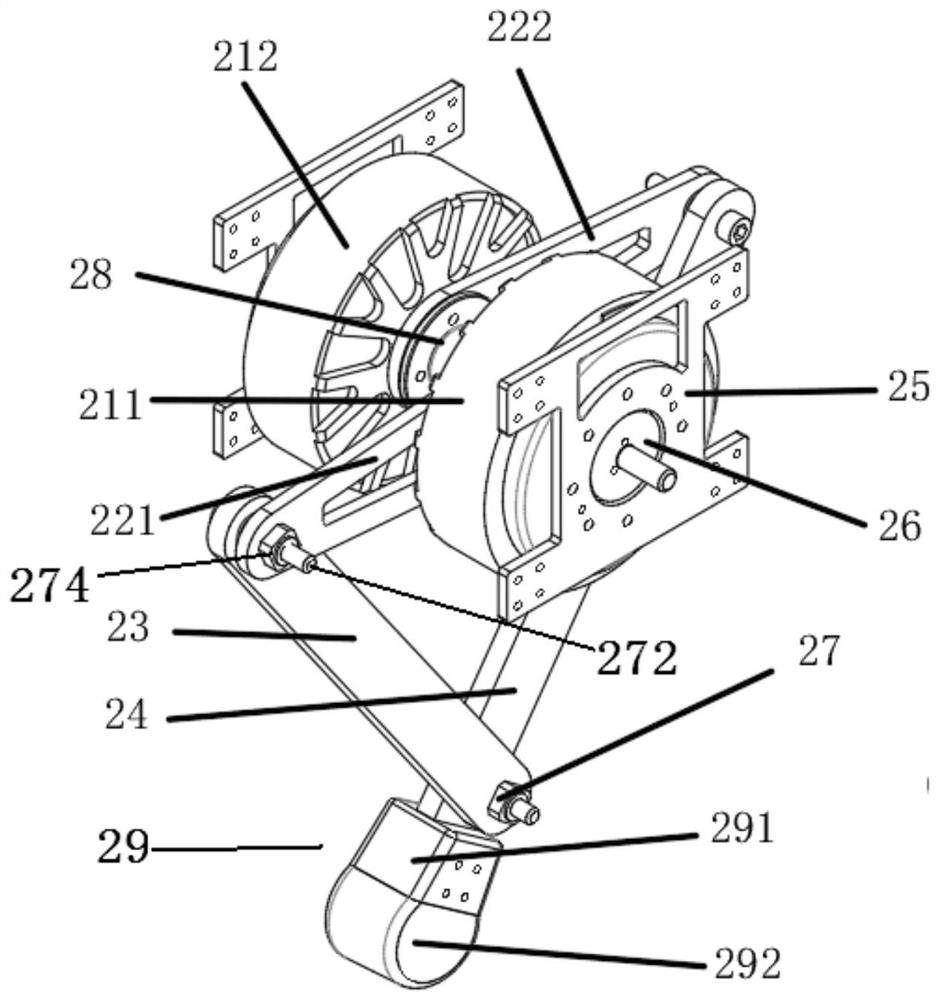

Clamping device used for fruit detection and classification

The invention discloses a clamping device used for fruit detection and classification. The clamping device comprises a clamping mechanism, a turnover mechanism, a transverse moving mechanism and a mounting platform. The mounting platform is oriented through two sliding rails, and the clamping mechanism, the turnover mechanism and the transverse moving mechanism are movably connected through the upper faces and the side faces of the sliding rails. The clamping device is characterized in that a turnover power cylinder drives a turnover power rack to move transversely while transverse movement of the turnover mechanism; the rack moves to drive a turnover transmission gear, a turnover transmission shaft and a turnover synchronous pulley to rotate; and the turnover synchronous pulley drives a clamping jaw to rotate through a synchronous belt, so that synchronous turnover movement of workpieces is achieved. The clamping device is reasonable in mechanism and convenient to use, the flip-over type automatic clamping function of the fruit loading process is achieved, operation is easy, fast and convenient, and working efficiency is effectively improved; and moreover, the fruit unloading function at any position can be achieved, fruit classification can be realized easily, and the practical value is quite good.

Owner:丹阳晨厷生物科技有限公司

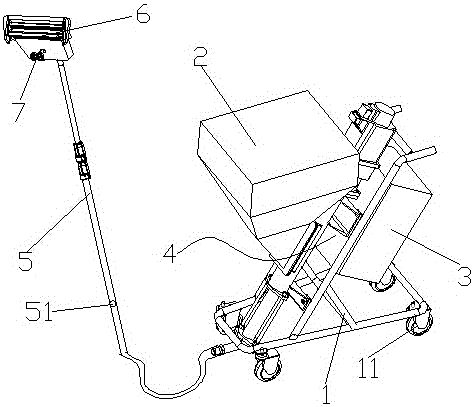

Program control wall processor

PendingCN106639269ALow cost without customizationThe cost of customization is not highBuilding constructionsNumerical controlElectric machinery

The invention discloses a program control wall processor. The program control wall processor comprises a rack, a storage hopper, a numerical control box, a material-sending pump mechanism, a handheld telescopic pole, a batch head mechanism and a supportive pulley block, wherein a discharge outlet of the storage hopper is connected with the material-sending pump mechanism, one end of the handheld telescopic pole is connected with the material-sending pump mechanism through a discharge hose and the other end is connected with the batch head mechanism. The handheld telescopic pole is provided with a trigger switch and the supportive pulley block is fixedly arranged on one side of the batch head mechanism. By the adoption of a servo motor along with a gear reducer to control feeding, the material-sending pump has the advantages of being high in accuracy, low in noise, smaller size and less weight on the whole, and more convenient in use and operation. By means of pulling a motor windlass together with a wire rope and extruding through spring pressure, a pressed board of the batch head mechanism has the advantages that the structure is simple and reasonable, accessories need not be customized and the cost is low, and the structure is detachable; in addition, damaged parts of the pressed board can be replaced directly and the cost of using is low; the effect of painting walls is very good and highly flat, and the requirements of clients and industry are met.

Owner:陈光

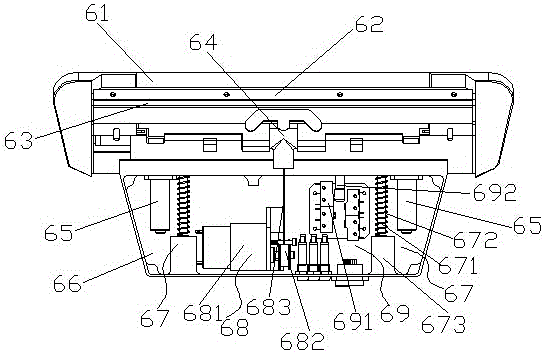

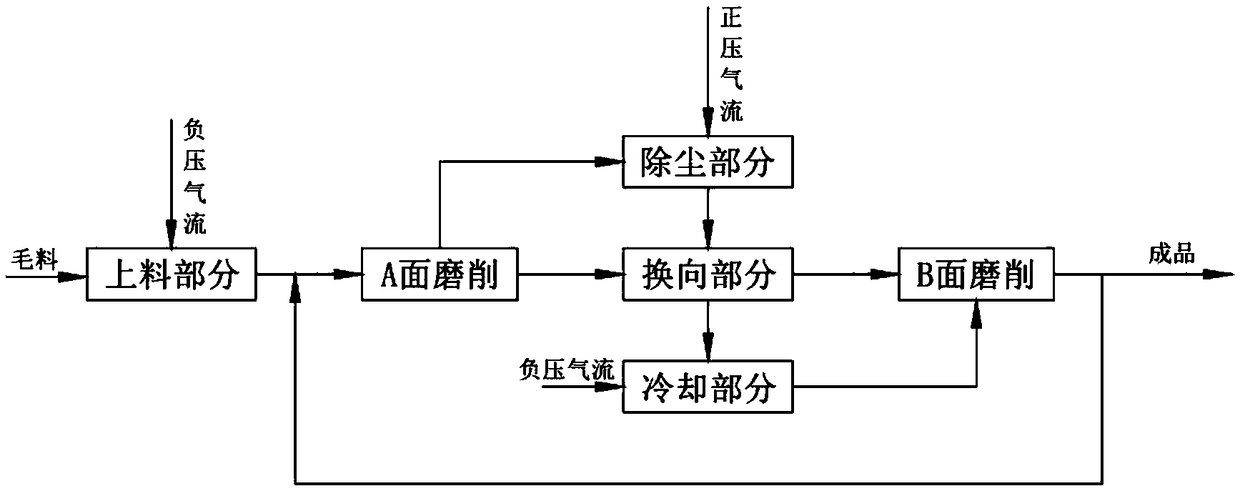

Machining method of ultra-thin graphite sample

The invention relates to the technical field of graphite sample machining, in particular to a machining method of an ultra-thin graphite sample. The machining method comprises the following steps of feeding, surface A grinding, reversing and surface B grinding and comprises the following specific steps that a blank is fixed on a positioning part B, then the graphite sample is driven to be in contact with a wheel, grinding is carried out on the surface A of the graphite sample, then upper and lower reversing is carried out on the graphite sample, and then the graphite sample is fixed on a positioning part A; then grinding feeding is carried out on the graphite sample, and then grinding is carried out on the surface B of the graphite sample; and repeated circulation grinding is carried out to obtain a finished product. According to the machining method, single reciprocating grinding is correspondingly carried out on the upper surface and the lower surface of the graphite sample in a circulating reversing manner of the upper surface and the lower surface, moreover, dust blowing is carried out on the grinding surfaces after single grinding by using positive pressure airflow, and cooling treatment is carried out in a negative pressure adsorption mode in the grinding process, so that the overall temperature and the grinding quality of the graphite sample in the grinding process can be controlled, and the technical problem that the machining quality of an ultra-thin graphite sample is difficult to control in the prior art are solved.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

Multi-section concrete pole automatic assembly and production device and assembly method thereof

InactiveCN108656340ASolve technical problems of low production efficiencyRealize automatic adjustmentAuxillary shaping apparatusPreformed elementsEngineeringMechanical engineering

The invention relates to the technical field of telegraph pole production, in particular to a multi-section concrete pole automatic assembly and production device and an assembly method thereof. The device comprises a reference table and an assembly mechanism; the reference table is provided with a placing module for placing main bodies of telegraph poles, and a positioning module arranged on theplacing module; the assembly mechanism comprises a support module for placing mounting bodies, a transmission module connected with the support module and driving the support module to move up and down, a limiting module arranged on one side of the support module for limiting the end parts of the mounting bodies, and a driving module for driving the mounting bodies, placed on the support module, to horizontally move to cooperate with main bodies on the placing module for outputting; the transmission module drives the mounting bodies, placed on the support module, to horizontally move down during axially limiting; the driving module drives the support module to operate in an intermittent transmission manner to realize automatic assembly and inputting / outputting of the mounting bodies and the main bodies; and the technical problem of low production efficiency in the prior art is solved.

Owner:湖州远通通讯器材有限公司

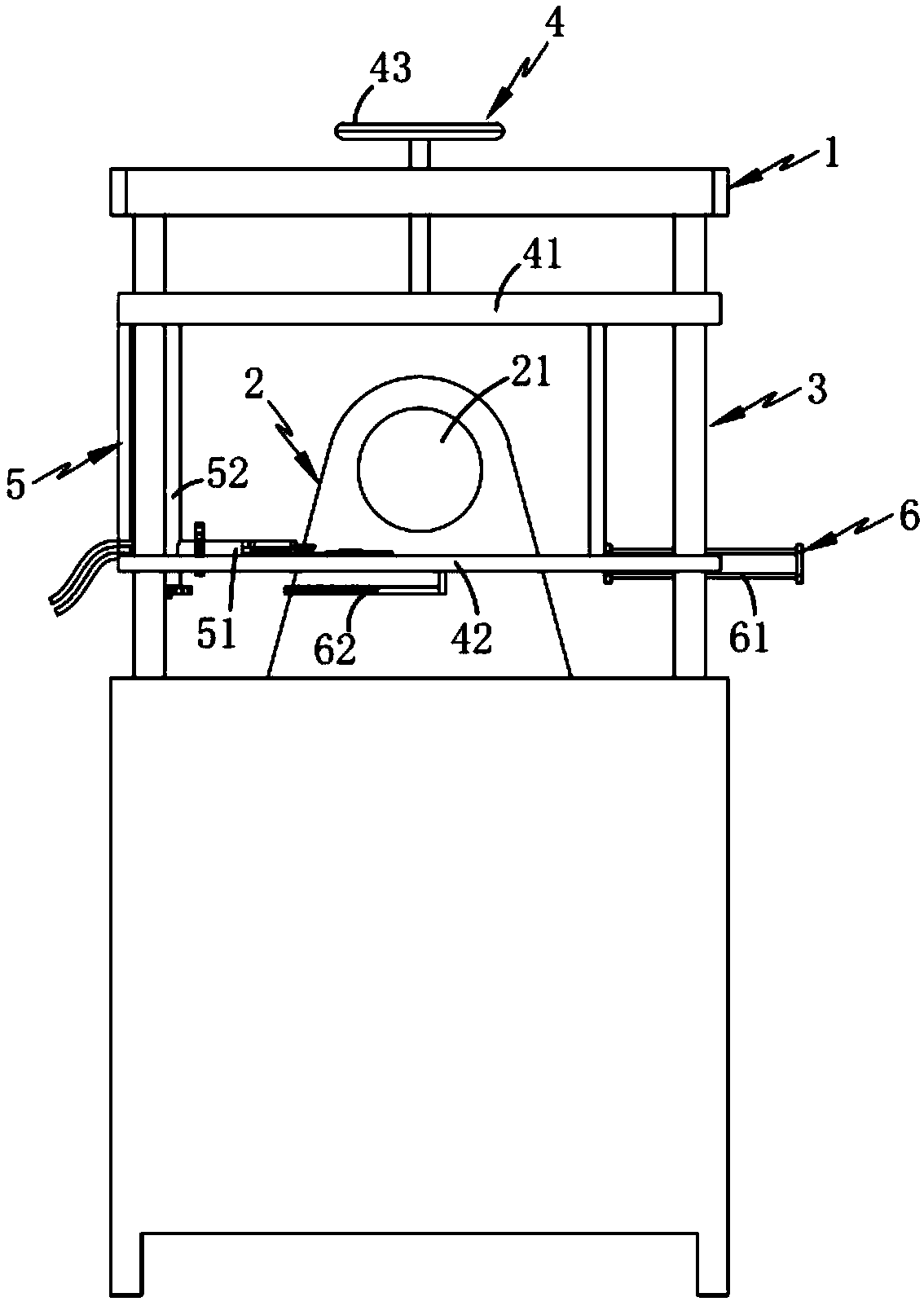

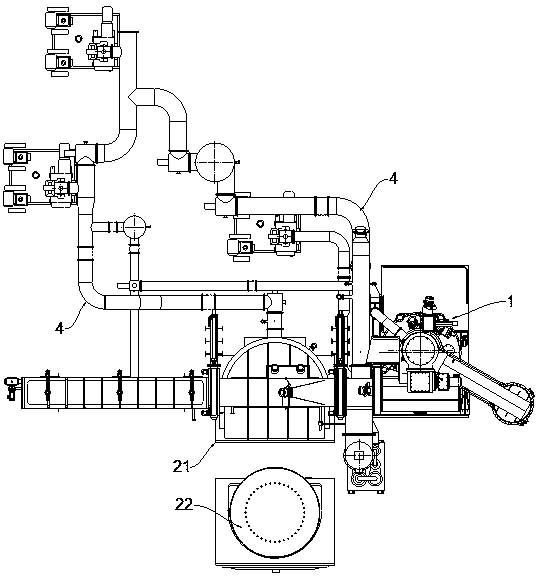

Vacuum induction smelting furnace

The invention discloses a vacuum induction smelting furnace which comprises a smelting room and an ingot casting room communicating through a runner. The smelting room comprises a furnace body which is supported by a furnace rack, wherein a crucible is arranged in the furnace body, an induction coil is arranged on the crucible, one end of the runner stretches into the smelting room, the crucible is located above the runner, and the crucible is also provided with an overturning driving mechanism which drives the crucible to pour molten liquor to the runner. The ingot casting room comprises an upper shell and a lower shell capable of being spliced to each other, wherein the upper shell communicates to the runner, the lower shell is supported by a sliding table which is supported by a slide rail, and the sliding table is provided with a translational driving mechanism which drives the sliding table to translate along a slide rail. The smelting room and the ingot casting room are separately provided with vacuumizing devices, the vacuumizing device arranged in the smelting room is connected to the furnace body, and the vacuumizing device arranged in the ingot casting room is connected to the upper shell; a plurality of filter baffle plates are arranged in the runner, and the filter baffle plates are successively arranged along the stretching direction of the runner. The vacuum induction smelting furnace is reasonable in mechanism and can carry out smelting and ingot casting separately.

Owner:SUZHOU ZHENHU ELECTRIC FURNACE +1

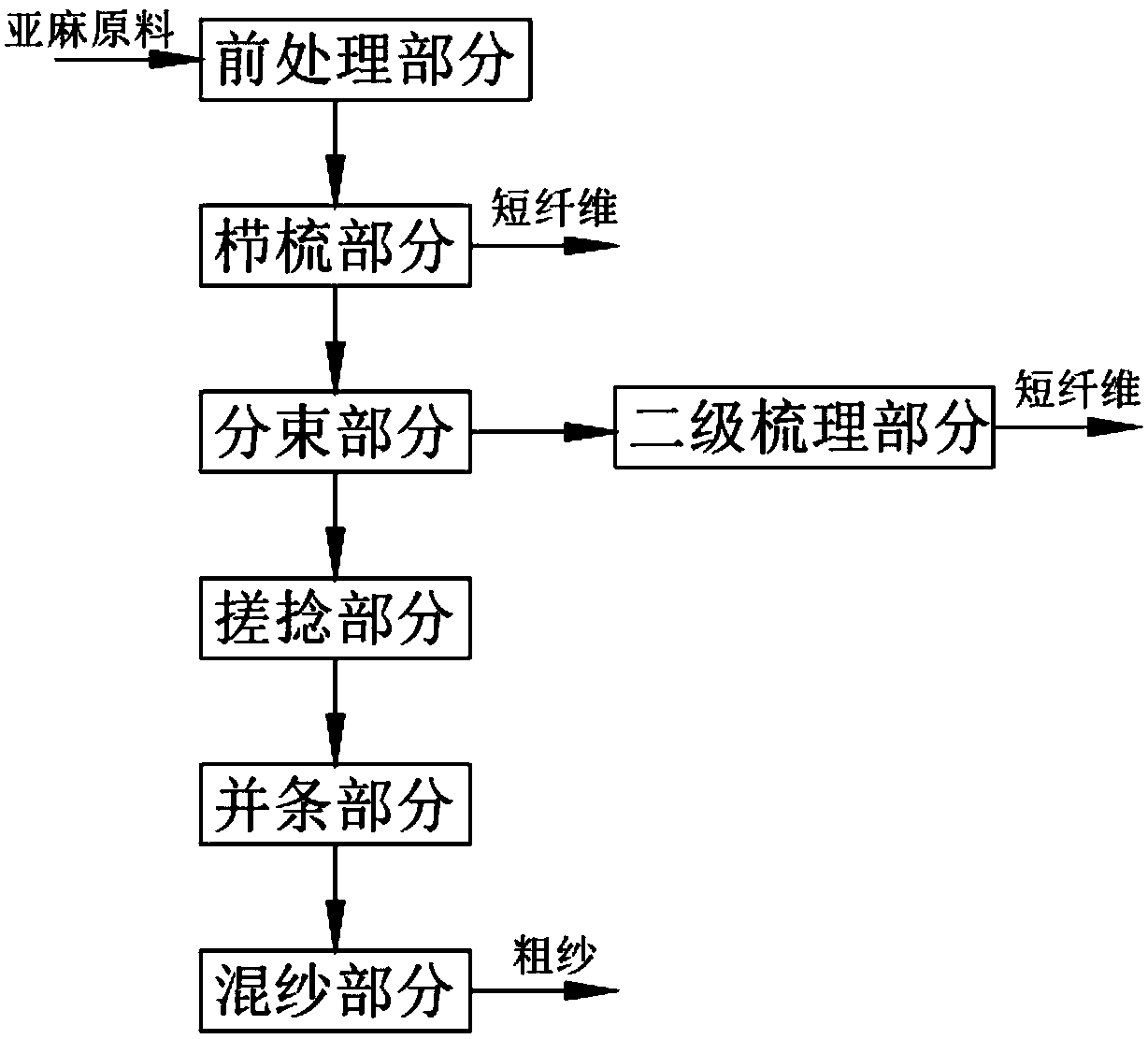

Continuous automatic production method of linen yarn

The invention relates to the linen yarn production technology field and especially relates to the continuous automatic production method of a linen yarn. A front processing portion, a heckling portion, a beam splitting portion, a twisting portion, a drawing portion and a blended yarn portion are included. After a linen raw material is split into a plurality of raw material bundles, a hackling machine carries out carding on the raw material bundles so as to obtain long fibers and short fibers. When the long fibers are transferred, the long fibers are split into bundles and the fiber bundles aresequentially pushed into an output component. Through the output component, the previous group of fiber bundles and the next group of fiber bundles in the output component are overlapped in an end-to-end mode, and during an output process, the fiber bundles are staggered and intertwined. A bundle splitting mechanism is used to split the long fibers in a directional transfer process through a guiding splitting mode, and then, the two adjacent groups of fiber bundles are directionally output in an end-to-end overlapping manner, and at the same time automatic winding is performed so as to realize the high-quality automatic production of linen splitting and lap joint. The technical problem of unstable yarn quality due to uneven artificial bundle splitting existing in the prior art is solved.

Owner:湖北蜀峰线业发展有限公司

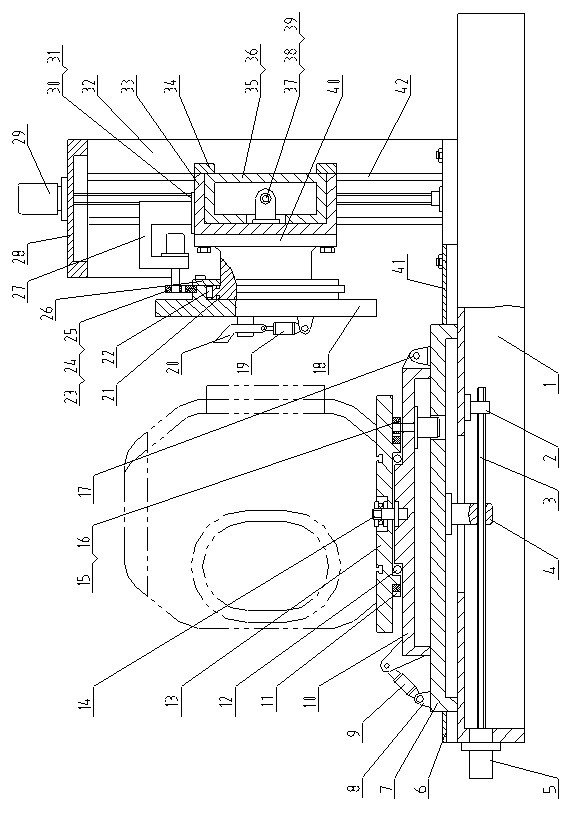

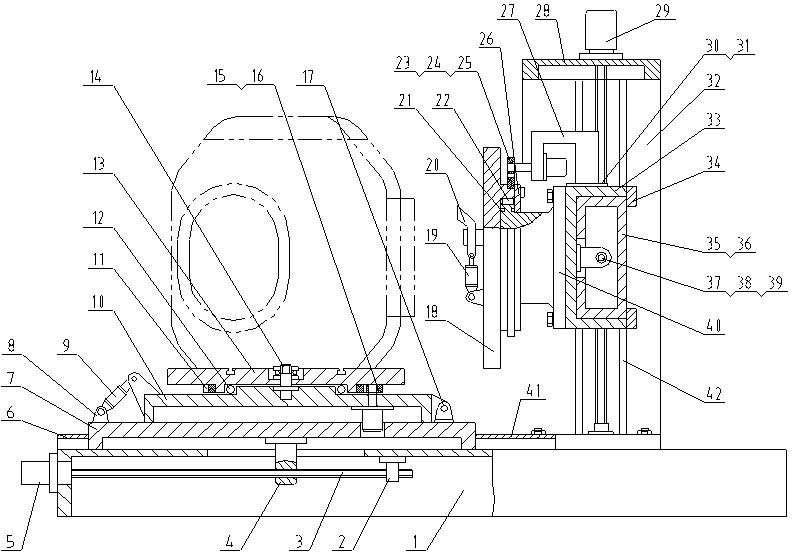

Casting flange flash push boring machine

InactiveCN102554357AReasonable organizationImprove applicabilityLarge fixed membersEngineeringUltimate tensile strength

The invention relates to a casting flange flash push boring machine, which comprises a base (1). A moving guide rail I (6) is arranged at the top of the base (1), a moving worktable (7) is arranged on the moving guide rail I (6), two vertical columns (32) are arranged in front of the moving guide rail I (6), a moving guide rail II (42) is arranged at the rear end of the two vertical columns (32),a beam (35) is arranged on the moving guide rail II (42), a sliding worktable (33) is arranged on the beam (35), a rotary tool rest support (40) is fixedly arranged on the rear end face of the sliding worktable (33), a rotary tool rest (18) is mounted on the rotary tool rest support (40), and a push boring mechanism (19) and a tool (20) is arranged on the rotary tool rest (18). The casting flangeflash push boring machine is reasonable in structure, high in applicability, short in machining time, high in production efficiency, safe and reliable, clamping is performed once, multiple stations are used for machining, and the labor intensity of operators is low.

Owner:JIANGYIN HUATEKANG MACHINERY

Direct-drive beam movable type numerical control planer boring and milling machine

InactiveCN102172843AReasonable organizationImprove working precisionFeeding apparatusEngineeringMovable type

Owner:NANTONG FUTONG MACHINE TOOL

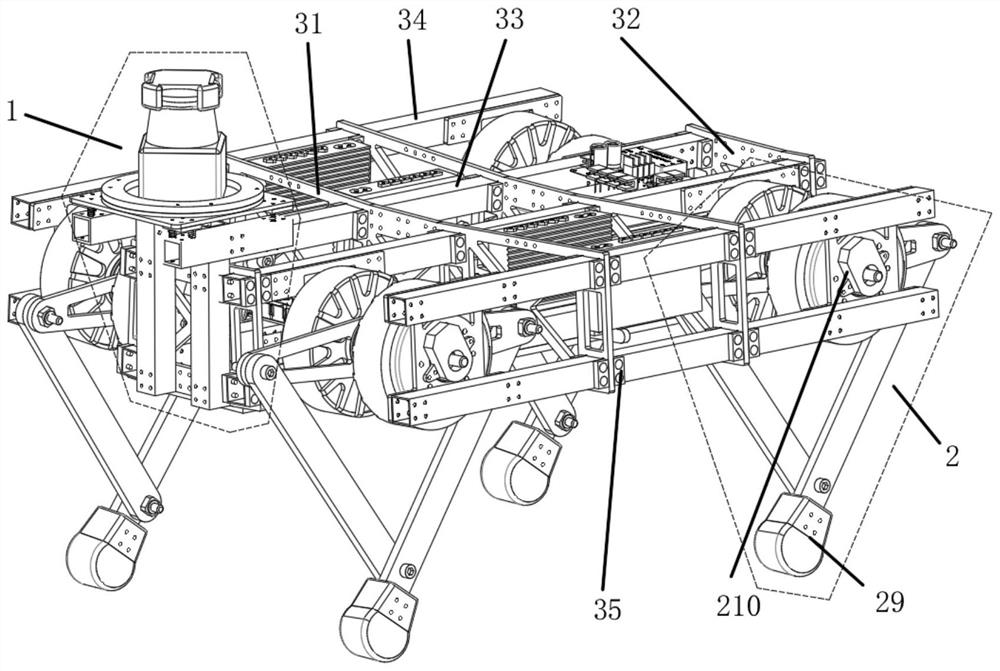

Eight-degree-of-freedom disc type brushless motor driven quadruped robot

ActiveCN111924019AReasonable organizationThe body frame is stable and lightEfficient propulsion technologiesVehiclesBrushless motorsDrive motor

The invention belongs to the field of robots, and relates to an eight-degree-of-freedom motor-driven quadruped bionic robot which comprises a robot body, a laser radar assembly, a leg structure and anelectric control system. Ideal motion forms of the four legs are realized by controlling a group of driving motors of each leg. The eight-degree-of-freedom motor-driven quadruped bionic robot has theadvantages that: a disc-type brushless counter-shaft placement motor driving mode is adopted, so that the driving mass ratio is large; the legs are of connecting rod structures, under the control oftwo coaxial driving sources, the transmission performance is good, and the effective area of the foot end is large; the left leg part and the right leg part are splayed, so that the stability in the running and jumping movement process is improved; and a coupling closing mechanism is used for increasing the rigidity of the legs between two driving motors of the connecting rod structure legs. According to the quadruped bionic robot, modular assembly design is adopted, disassembly and assembly are convenient, the structure is compact, the robot body frame is stable and light, design is reasonable, the entrance threshold of quadruped robot research can be lowered, and the investigation and movement capacity of the quadruped robot is improved.

Owner:UNIV OF SCI & TECH BEIJING

Automatic refractory brick demoulding production mechanism

InactiveCN108501194AAvoid damageSolve the technical problem of lossDischarging arrangementBrickRefractory

The invention relates to the technical field of refractory material production, in particular to an automatic refractory brick demoulding production mechanism. The automatic refractory brick demoulding production mechanism comprises a rack, a bearing table, a demoulding assembly and an output assembly. The demoulding assembly comprises a removal part A, a removal part B, a removal part C and a drive part driving the removal part A, the removal part B and the removal part C to move. A forming die containing area is formed between the removal part A and the removal part B, the containing area islocated on the bearing platform, and the removal part A and the removal part C are arranged in a transmission connection manner. The output assembly comprises a first output part and a second outputpart, after a side limiting die A and a side limiting die B are separated from green bricks through the removal part A and the removal part B, the green bricks are transferred to the first output partand the second output part. A removal assembly A and a removal assembly B synchronously remove the side limiting die A and the side limiting die B in the horizontal direction in a synchronous reversehorizontal movement motion manner, automatic, stable and horizontal green brick demoulding is achieved; and the technical problem that in the prior art, the green bricks are consumed in the manual demoulding process is solved.

Owner:CHANGXING RUIHONG REFRACTORY MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com