Transshipment anchor rod and anchor cable drill carriage

A technology for anchor cables and drilling rigs, which is applied in the installation of anchor rods, drilling equipment, earthwork drilling and mining, etc. It can solve the problems of unsatisfactory support efficiency, harsh working environment, and low degree of mechanization, and achieve safe and reliable operating conditions. Excavation efficiency, reasonable effect of the overall mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

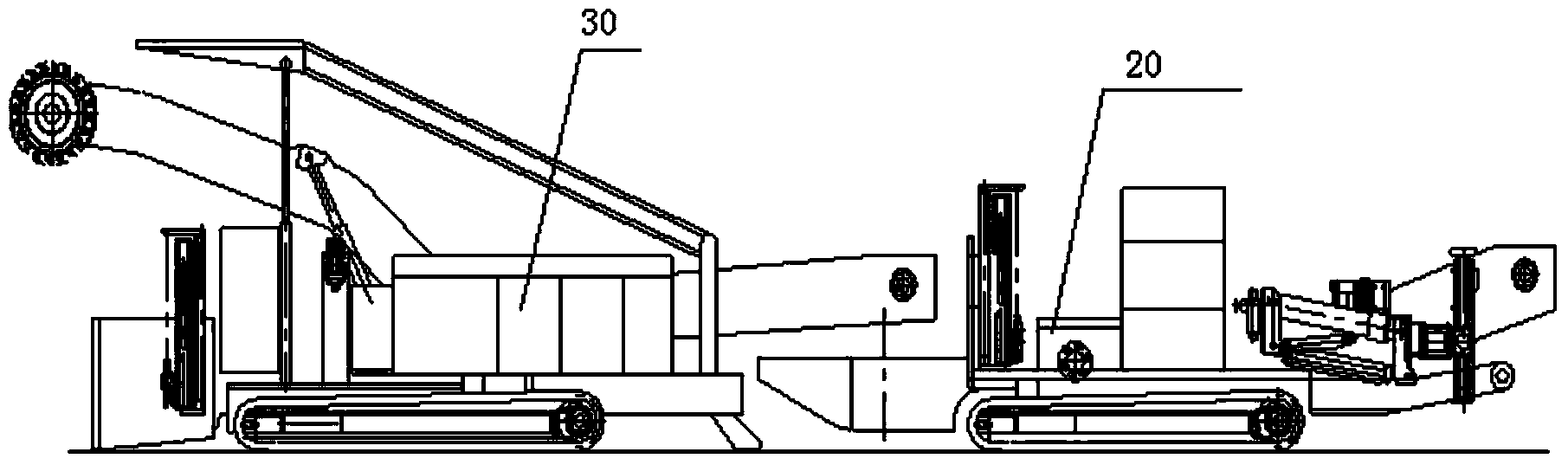

[0030] Refer to attached figure 1 It can be seen that the transfer anchor rod and cable drilling truck 20 of the present invention follows the anchor digging equipment 30, and has the transfer function of transferring the coal cut by the anchor digging equipment 30 to the bridge belt conveyor or shuttle car, and has a mechanized top. The supporting function of anchor cable bolt and gang bolt also has the crushing function of breaking the large coal block and preventing the conveying equipment from being smashed.

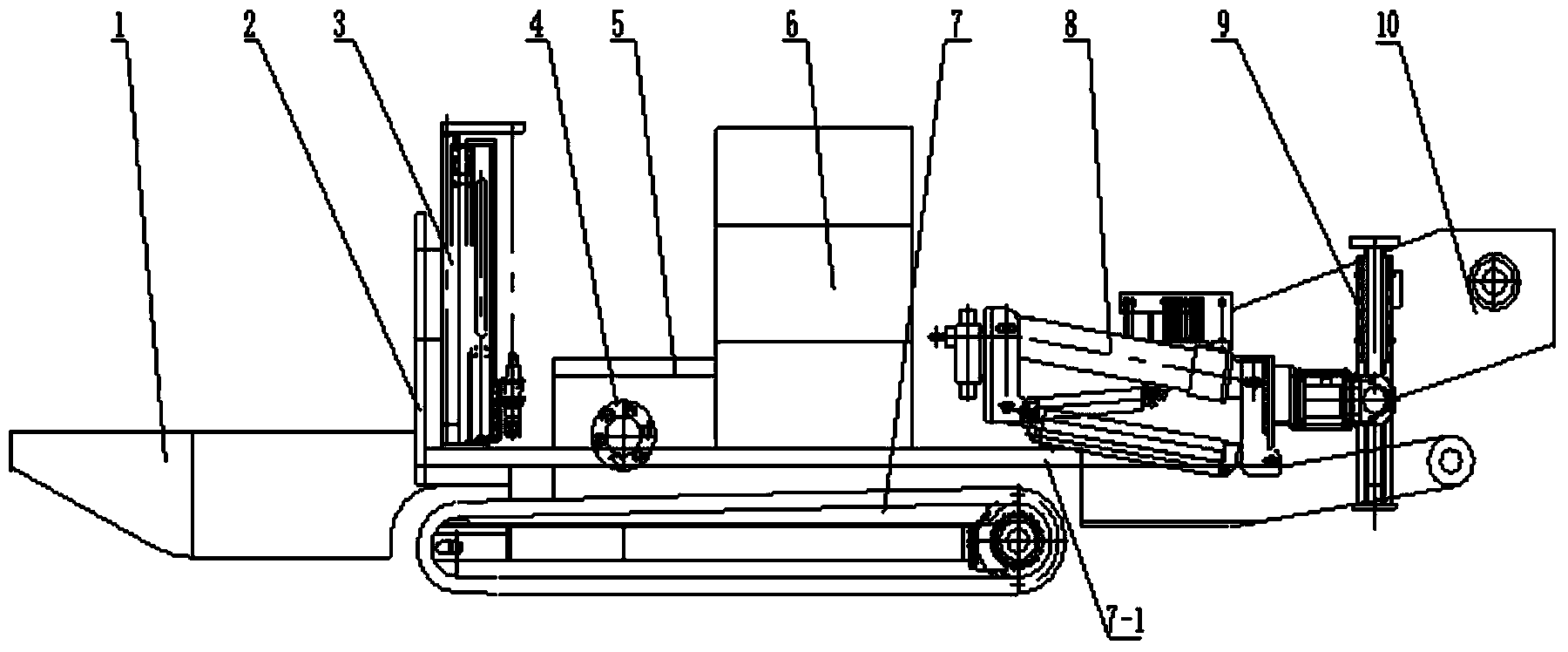

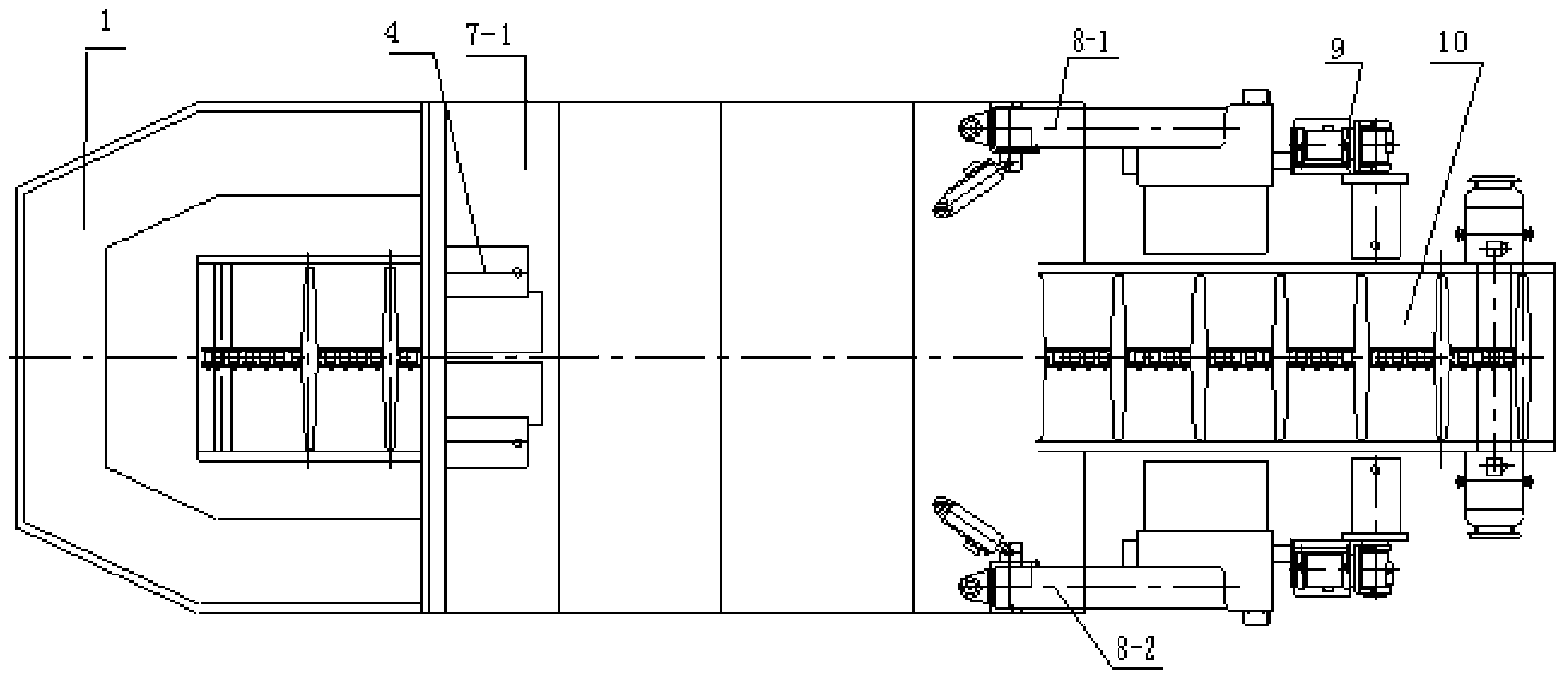

[0031] As an embodiment of the present invention, refer to the attached Figures 2 to 5 It can be seen that the transfer anchor rod and cable drilling vehicle 20 of the present invention includes a self-propelled mechanism 7, a transfer mechanism, a support mechanism, a crushing mechanism, an electrical system 6 and a hydraulic system.

[0032] The self-propelled mechanism 7 is positioned at the bottom of the rig, and its top is provided with an installation platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com