Program control wall processor

A processing machine and program-controlled technology, which is applied in the direction of construction and building construction, can solve the problems of unsatisfactory wall painting effect, inconvenient operation and use, and insufficient flatness, so as to achieve low cost of use, high precision, and high flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

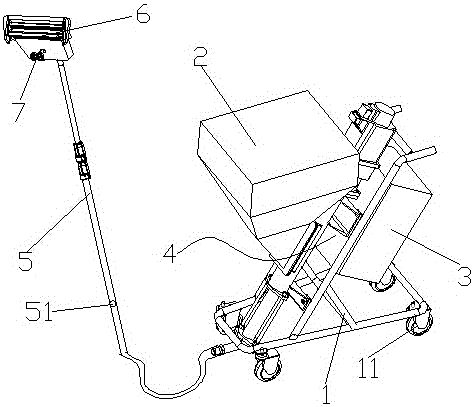

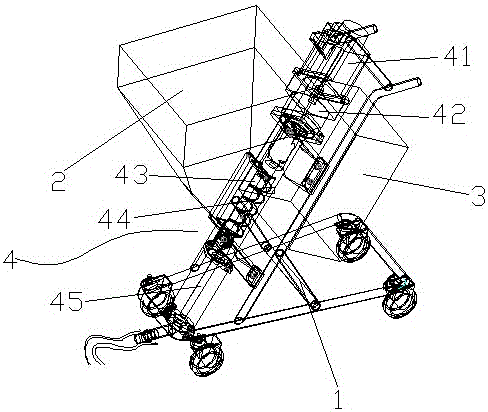

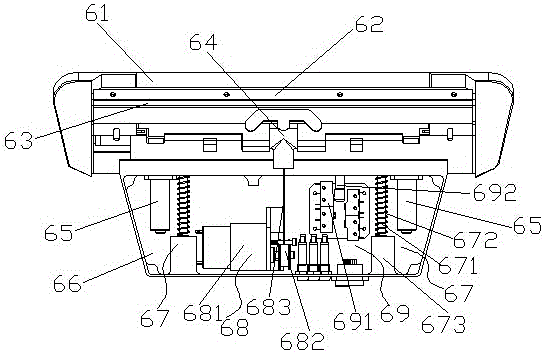

[0020] see figure 1 , a program-controlled wall surface treatment machine, including a frame 1, a storage hopper 2, a numerical control box 3, a pump material delivery mechanism 4, a hand-held telescopic rod 5, a flapping mechanism 6 and a supporting pulley block 7, and the storage hopper 2 is arranged on the machine Right above the frame 1, the numerical control box 3 is fixedly arranged on one side of the frame 1, the discharge port of the storage hopper 2 communicates with the pump material delivery mechanism 4, and one end of the hand-held telescopic rod 5 is connected to the delivery tube through the discharge hose. The pumping mechanism 4 is connected, and the other end communicates with the capping mechanism 6. The hand-held telescopic rod 5 is provided with a trigger opening 51, and the supporting pulley block 7 is fixed on one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com