Modular microbial fuel cell electrode reactor

A technology of fuel cell electrodes and microorganisms, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve the problems of easy swing, low reaction efficiency, unstable biofilm, etc., to achieve convenient connection, high reaction efficiency, and enhanced denitrification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

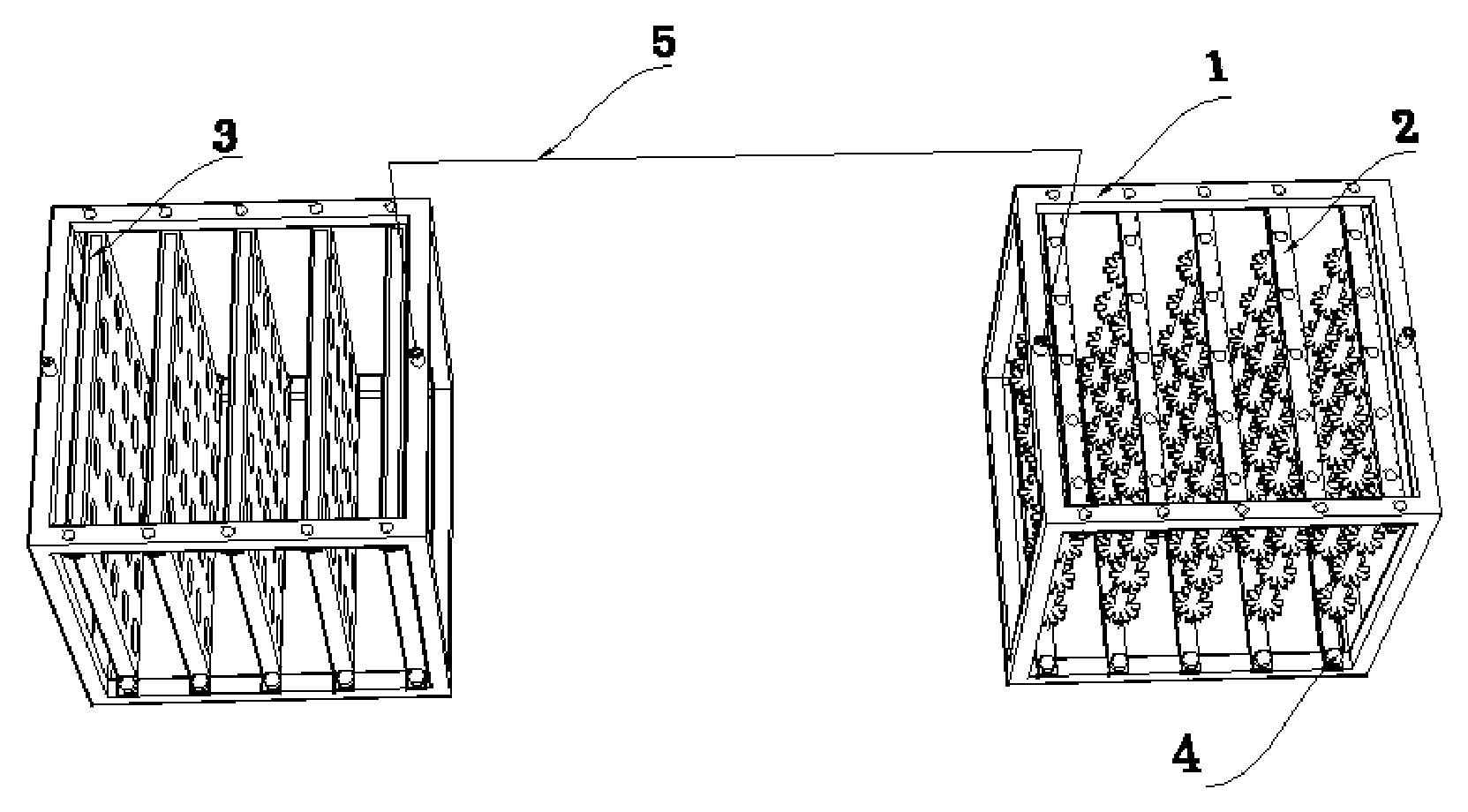

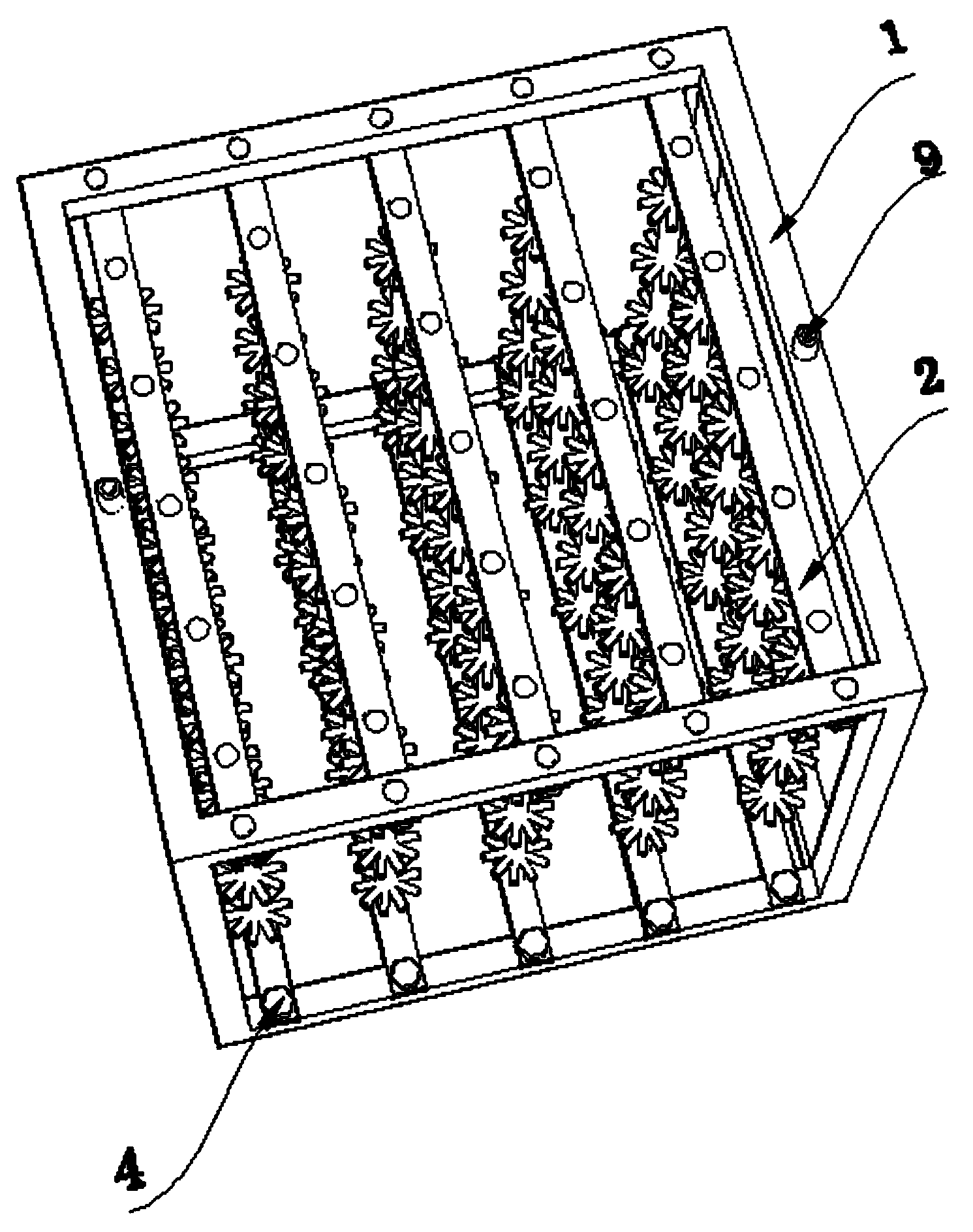

[0025] Such as figure 2 As shown, an electrode stack using a suspended electrode unit (2) includes: a casing (1), a suspended electrode unit (2), and a unit fixing member (4). shell(1) such as Figure 4 As shown, it includes an outer casing (6), a cell connection part (7) and an electrode stack connection part (9). The outer casing (6) is made of PE material, with a size of 100cm*100cm*100cm, and each side is a hollow cuboid with a height of 5cm. according to Figure 4 Drill holes with an outer diameter of 3cm and a hole spacing of 20cm. The connecting part of the monomer (7) selects nuts, and presses the nuts with a diameter of 3cm, an opposite side of 5cm, and a thickness of 1cm. Image 6 , Figure 7 Align with the hole to secure. The electrode stack connection part (9) adopts a double-layer bottomless hollow cylinder, the outer layer is made of PE material, and the inner layer is made of aluminum alloy material. The electrode stack connection part (9) with an outer d...

Embodiment 2

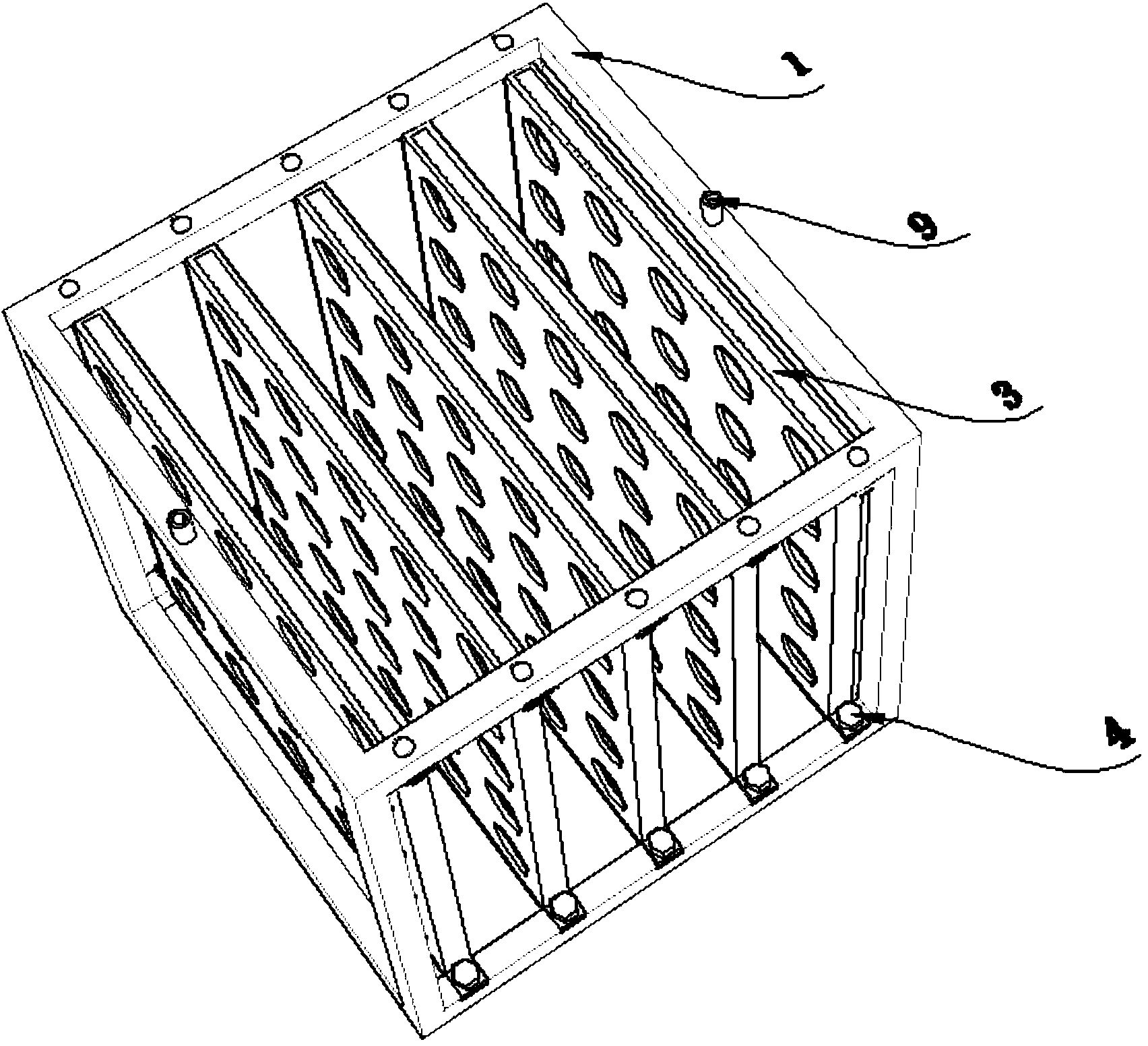

[0027] Such as image 3 As shown, an electrode stack using a filled electrode monomer (3) includes: a casing (1), a filled electrode monomer (2), and a monomer fixing member (4). The shell (1) is the same as the shell (1) in the first embodiment. according to Figure 9 Make the filled electrode monomer (3), the electrode monomer shell (13) is made of aluminum alloy, the hollow cuboid part in the middle is 90cm long, 5cm wide, and 90cm high, and extends horizontally by 5cm from top to bottom, left and right, and punches holes in the extension with an aperture of 3cm , 25 holes are opened at the front and back, and the hole diameter is 5cm. Pack conductive materials with large specific surface area that can be stacked, such as carbon particles, carbon felt, graphite foam, etc., into the electrode monomer casing (13) as filling materials. Such as Figure 10 , Monomer fixture (4) selects screw for use, external diameter 3cm, pitch 0.2cm, long 5cm. according to image 3 To as...

Embodiment 3

[0029] Applied in AAO process. The AAO process is a combination of traditional activated sludge process, biological nitrification and denitrification process and biological phosphorus removal process. Since the process alternately operates three different environmental conditions of anaerobic, anoxic and aerobic, there will be a variety of facultative anaerobic fermentation bacteria, denitrifying bacteria, aerobic phosphorus-accumulating bacteria, etc. Microorganisms in the environment. Different types of microbial flora coexist in the same sludge system, and there must be competition among bacteria with different sludge ages and carbon sources. Due to the existence of the above contradictions, it is difficult for the system to achieve the optimal growth conditions of the three bacteria with different functions, so the denitrification efficiency of this process is generally not high.

[0030] Applying the invention to the AAO sewage treatment process can strengthen microorga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com