Production process for treating bone-shaped paint film of flat enameled wire

A production process and enameled wire technology, which is used in heat treatment equipment, used to reduce the size of conductors/cables, and to insulate conductors/cables, etc. It can solve the difficulties in breaking through the core technical barriers of flat enameled wires, product electrical properties and adhesion Can not meet the standard, VOC amount is not up to the standard and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

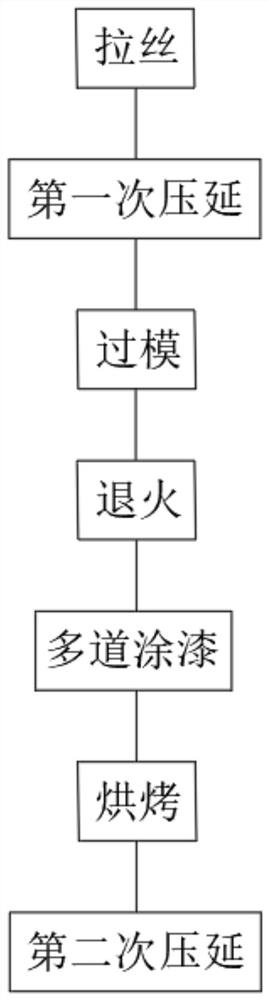

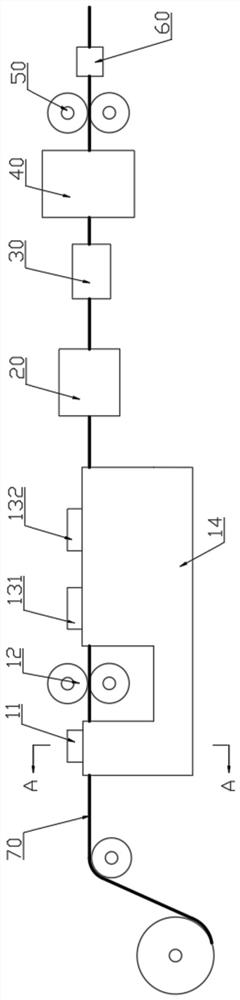

[0054] see Figure 1 to Figure 9 , a kind of production technology of processing flat enameled wire bone-shaped paint film of the present embodiment, comprises the following steps:

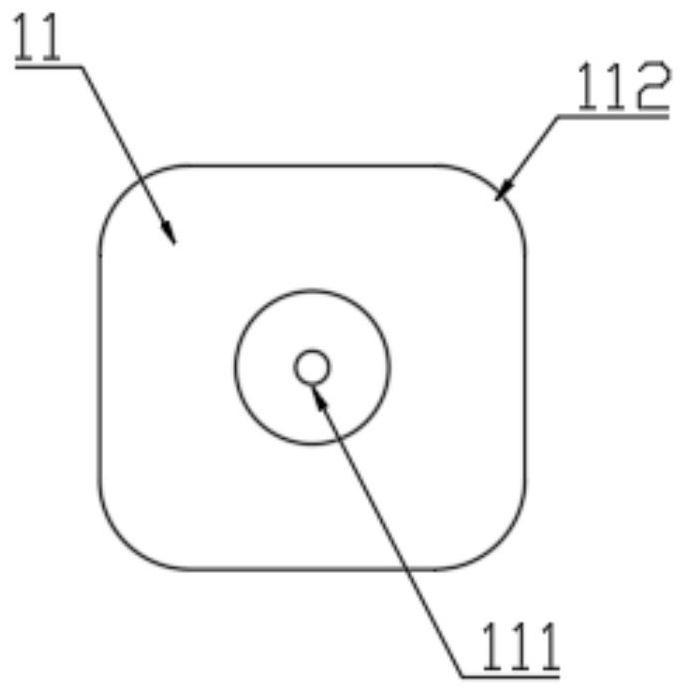

[0055] Step 1, wire drawing: draw the bare wire 70 into the required round wire specification through the round wire die 11;

[0056] Step 2, rolling for the first time: rolling the round wire for the first time by the first rolling machine 12;

[0057] Step 3, overmolding: drawing the bare wire 70 into a flat wire of the required specification through a flat wire mold;

[0058] Step 4, annealing: annealing the flat wire through the annealing device 20;

[0059] Step 5, multi-layer painting: the annealed flat wire is subjected to multi-layer painting treatment by the painting device 30 to form a flat enameled wire, and the thickness of the painted film is thicker than that of the required specification;

[0060] Step 6, baking: the flat enameled wire is baked by the baking device 40;

[0061] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com