Root cutting harvest device for vegetables planted by modern greenhouse atomization

A harvesting device and root cutting technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of wasting manpower and material resources, affecting economic benefits, etc., and achieve the effects of convenient installation and maintenance, obvious economic benefits, and reasonable organization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

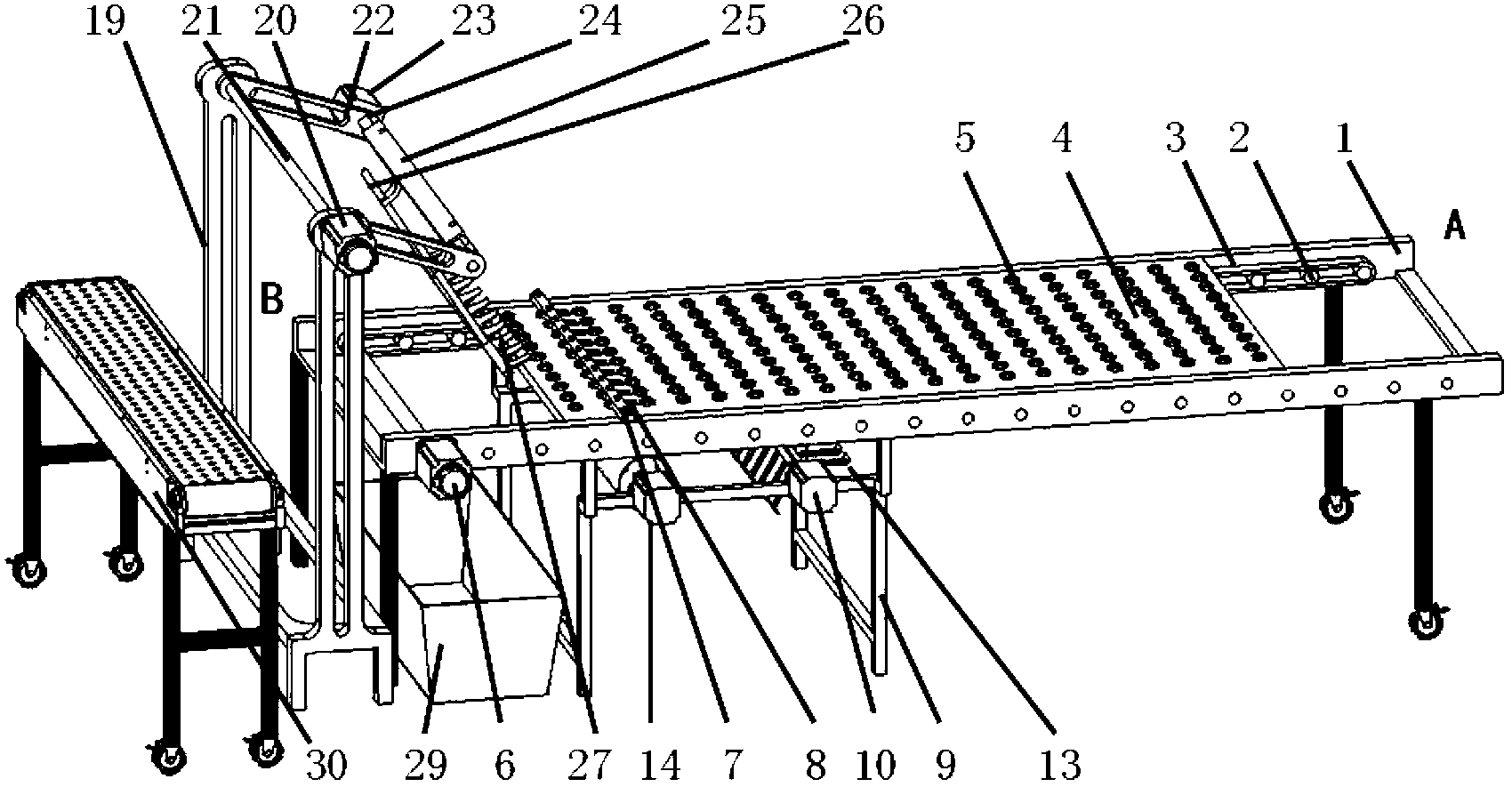

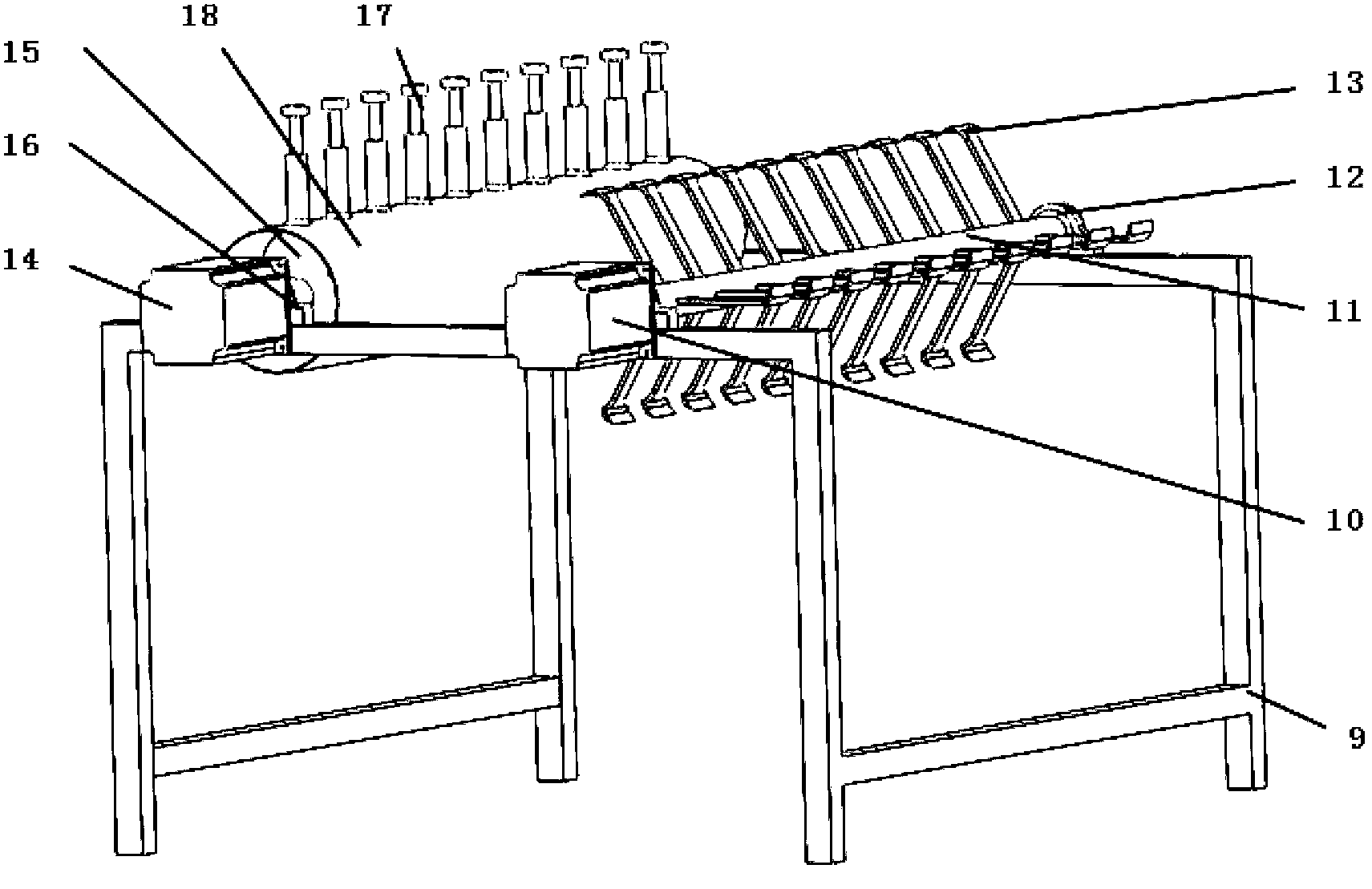

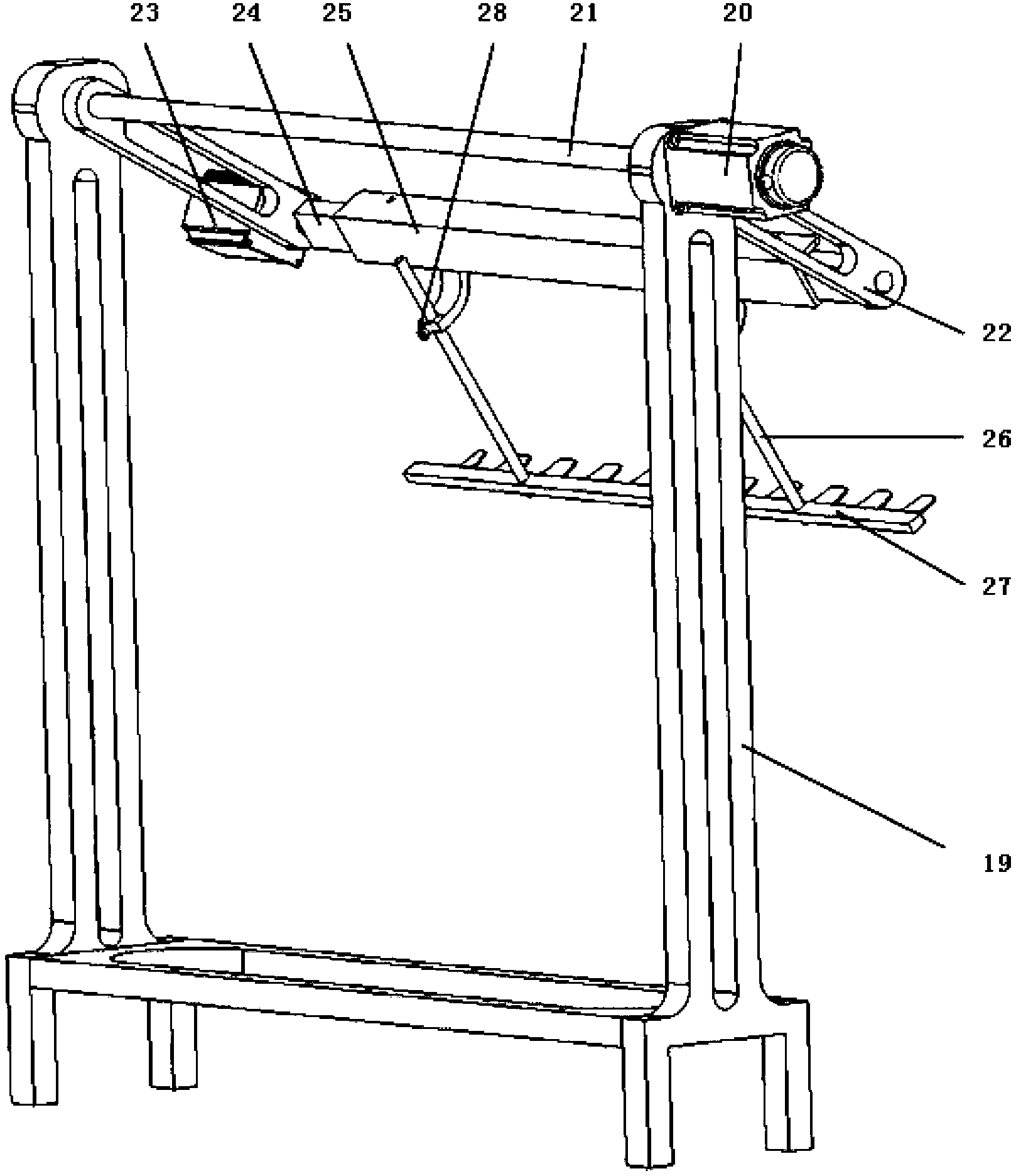

[0024] Such as figure 1 As shown, a root cutting and harvesting device for greenhouse atomized cultivated vegetables of the present invention is suitable for modern greenhouse vegetable planting techniques. The device includes a transmission mechanism, a root cutting mechanism, a transfer mechanism and a cup-ejecting mechanism. The transmission mechanism includes a transmission bracket 1, two rows of transmission wheels 3 are respectively installed on both sides of the transmission bracket 1, the transmission belt 2 is installed on the transmission wheels 3, and the output shaft of the transmission motor 6 is connected to the first one of a row of transmission wheels 3 through a coupling. The benzene plate 4 straddles the two conveyor belts, the planting cup 5 is placed in the hole of the benzene plate 4, the pressing needle mounting seat 7 is installed across the transmission bracket 1, and a row of pressing arrays 8 is fixed on the pressing array by screws. On the mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com