Continuous automatic production method of linen yarn

An automatic production method, flax technology, applied in the direction of yarn, textile and papermaking, fiber processing, etc., can solve the problems of uneven artificial bundling, unstable yarn quality, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0045] According to the drawings in the manual figure 1 A continuous automatic production method of flax yarn in this embodiment is described.

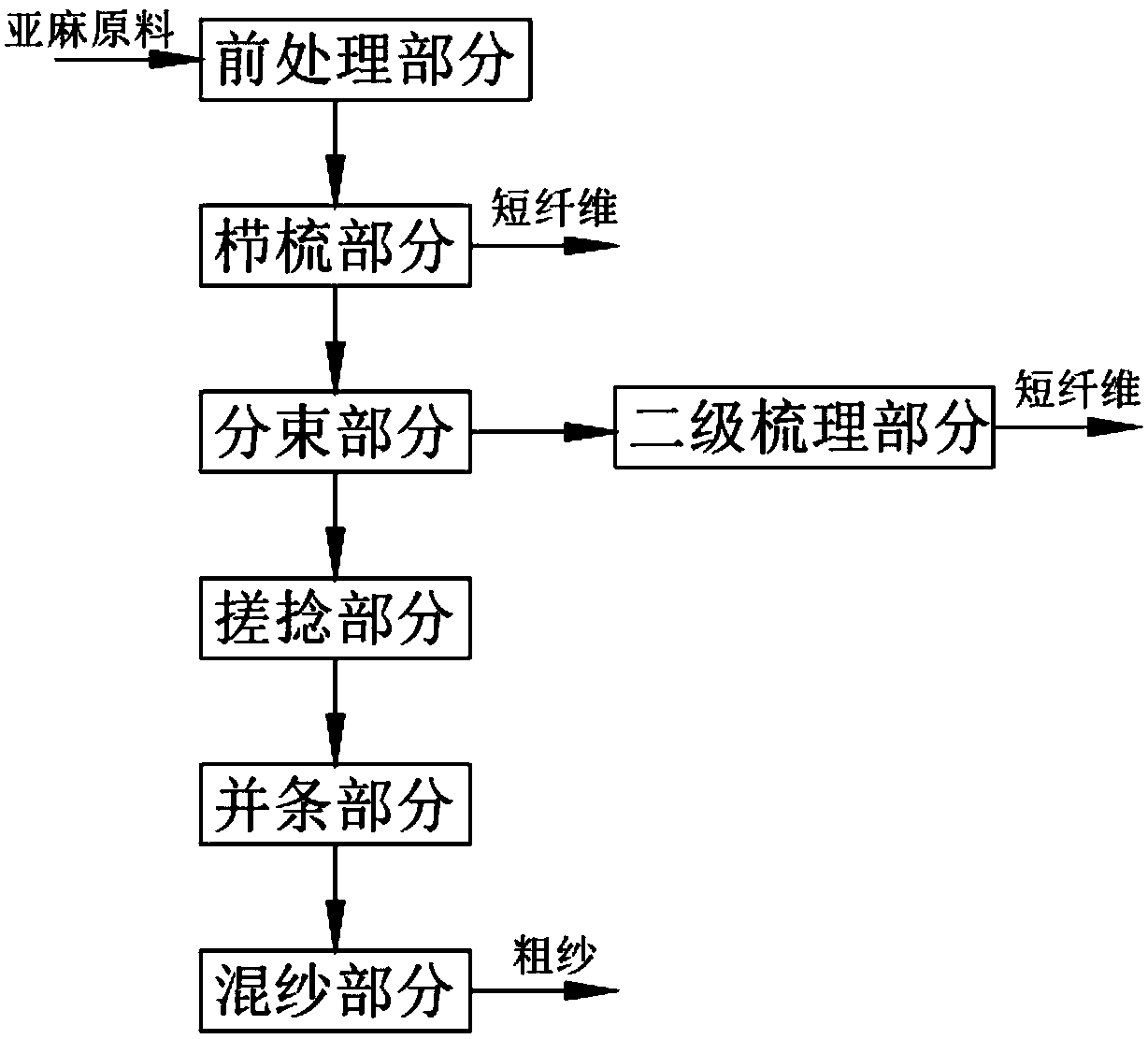

[0046] A continuous automatic production method of flax yarn, comprising the following parts:

[0047] (a) the pre-processing part, the flax raw material in the roll shape is unfolded in a rolling transmission mode by the raw material pre-processing device 4, and is automatically divided into several uniform raw material bundles 41 during the unfolding process;

[0048] (b) combing par...

Embodiment 2

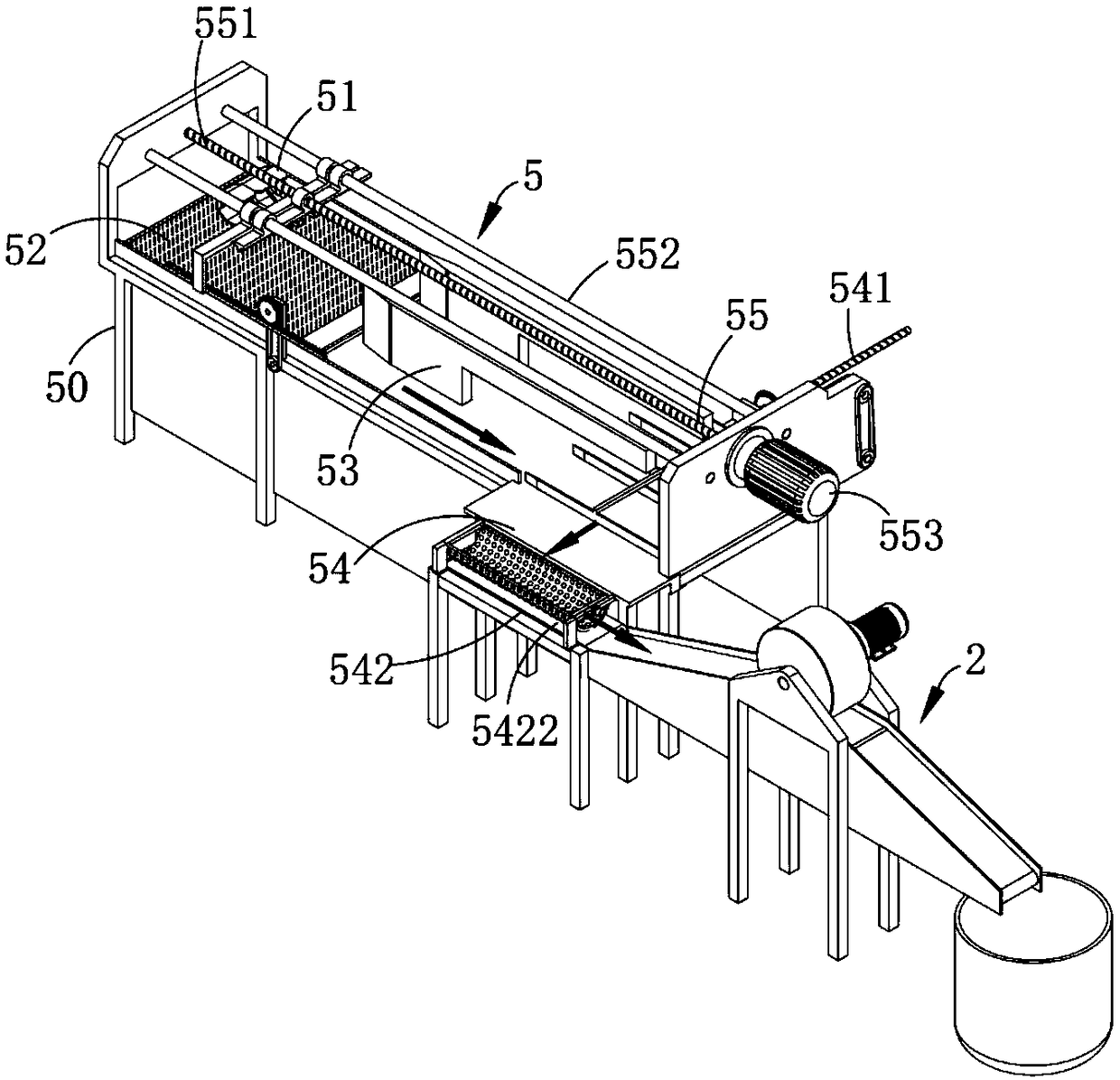

[0056] Wherein, the same or corresponding parts as those in the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below; the difference between the second embodiment and the first embodiment is that : the output assembly 542 drives a number of balls 5424 arranged in the swing groove 5422 to rotate through the transmission belt 5421 on the friction drive, and the fiber bundles 20 in the swing groove 5422 are oriented and output by the balls 5424.

[0057] Specifically, the swing groove 5422 is separated from the swing groove 5422 after being driven by the friction block 5413 to swing in a directional manner, and the swing groove 5422 is reset by its gravity, so that the reciprocating swing of the swing groove 5422 drives the fiber bundle 20 inside to wind.

[0058] As an improvement, the step (c) also includes a secondary combing part. During the long fiber...

Embodiment 3

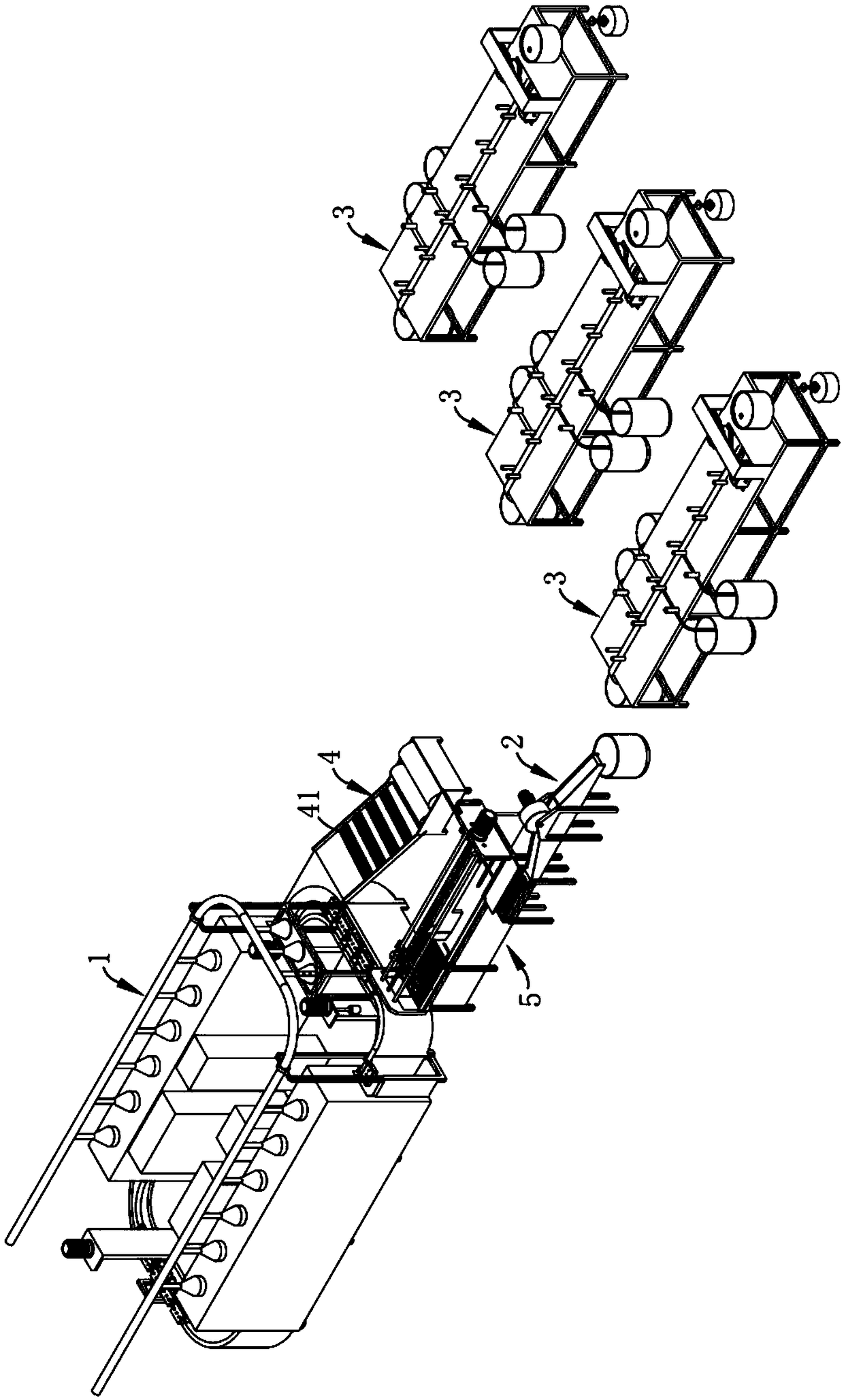

[0062] According to the manual attached Figure 2-16 A continuous automatic production line of flax yarn in this embodiment is described.

[0063] Such as Figures 2 to 5 Shown, a kind of flax yarn continuous type automatic production line comprises combing machine 1, drawing frame 2 and yarn blending machine 3, is characterized in that, also comprises:

[0064] Raw material pre-processing device 4, said raw material pre-processing device 4 is located at the front section of said combing machine 1, and it is used to divide the flax raw material that is roll into several uniform raw material bundles 41; The combing machine 1 combs to form long fibers 10 and short fibers respectively, and the long fibers 10 are transferred to the next station through the combing machine 1;

[0065] Long fiber automatic feeding device 5, the long fiber automatic feeding device 5 includes a frame 50, a traction mechanism 51, a beam splitting mechanism 53 and a feeding mechanism 54; the long fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com