Casting flange flash push boring machine

A flange and flash technology, which is applied in the field of casting flange flash pusher, can solve the problems of operator injury and high labor intensity, and achieve the effects of reduced labor intensity, short processing time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

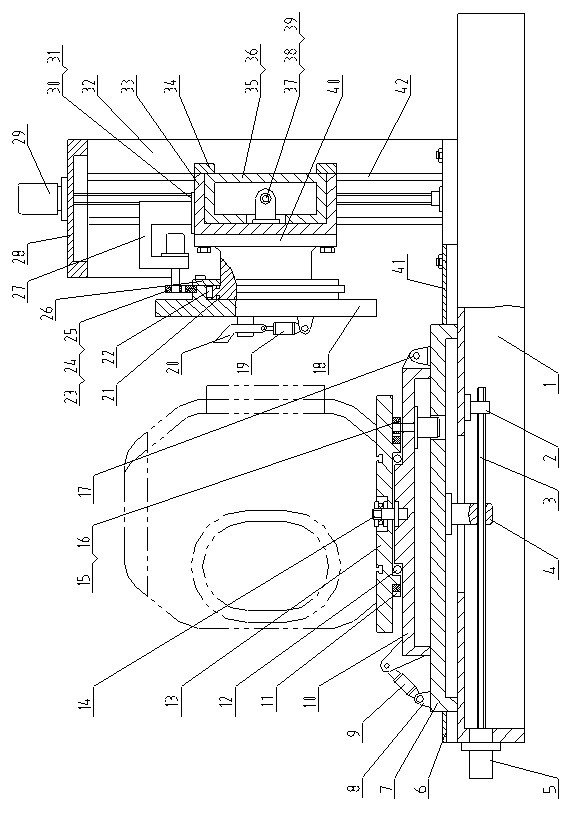

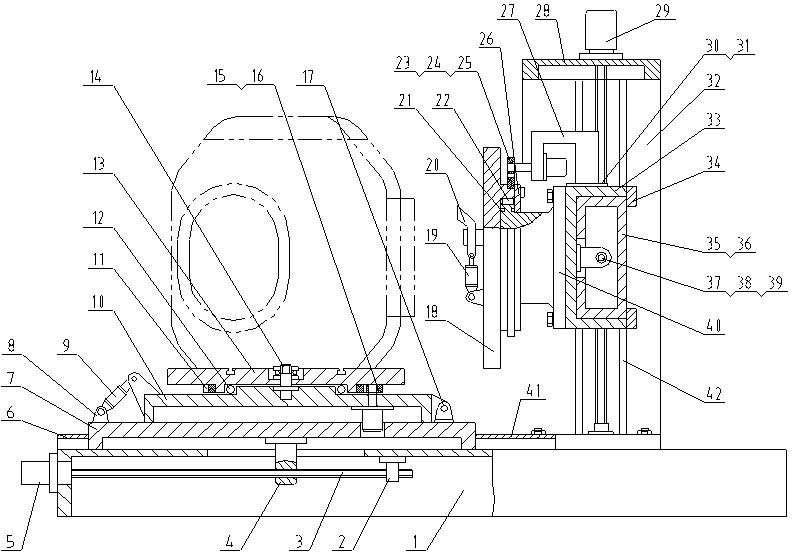

[0057] see figure 1 , the present invention relates to a casting flange flash pusher, which includes a base 1, a moving guide rail I6 is provided on the top of the base 1, a screw seat 2 is provided at the bottom of the base 1, and a screw seat 2 is provided behind the screw seat 2 Screw rotation mechanism I5, the screw rotation mechanism I5 is arranged on the rear end of the base 1, a moving screw I3 is connected between the screw seat 2 and the screw rotation mechanism I5, and a nut seat I4 is set on the moving screw I3. A mobile workbench 7 is installed on the mobile guide rail 16 through a mobile workbench pressing plate 41, the nut seat 14 is fixedly arranged on the bottom of the mobile workbench 7, and the top of the mobile workbench 7 is provided with a tilting workbench 10, and the tilting work The front of the table 10 is provided with a support II17, and the rear of the inclined workbench 10 is provided with a support I8. Connected by the lifting mechanism 9, the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com