Direct-drive beam movable type numerical control planer boring and milling machine

A mobile, beam technology, applied in the field of machine tools, can solve the problems of poor reliability and low working accuracy of machine tools, and achieve the effects of high reliability, reasonable structure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

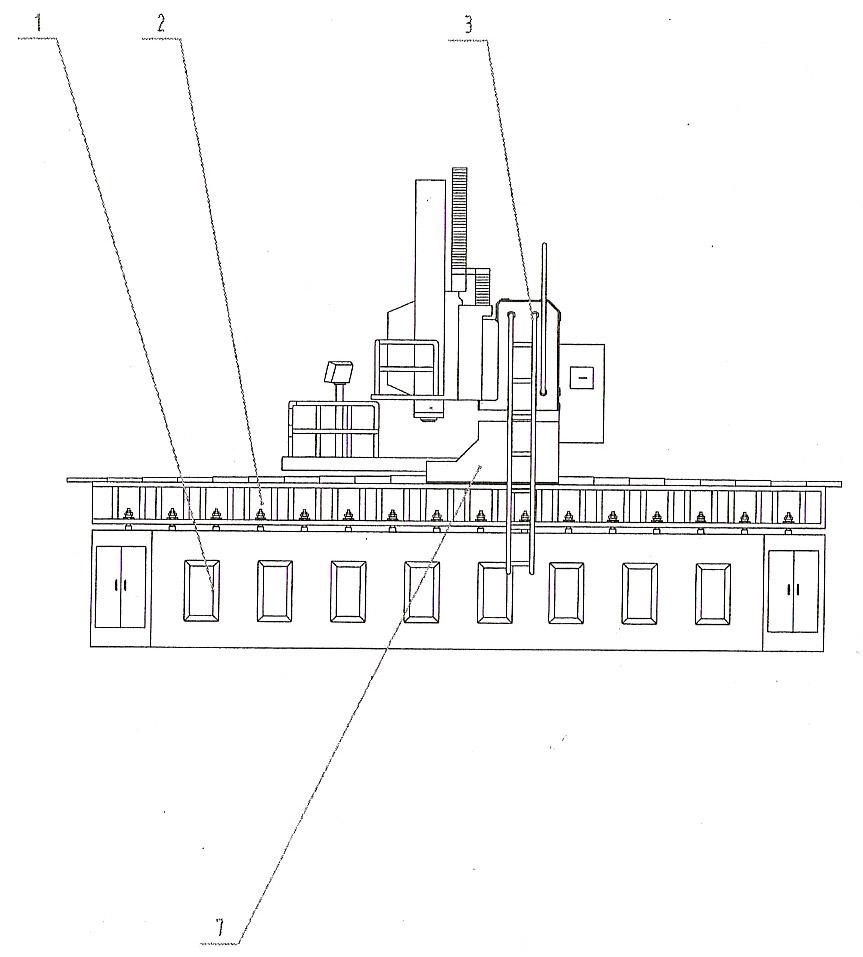

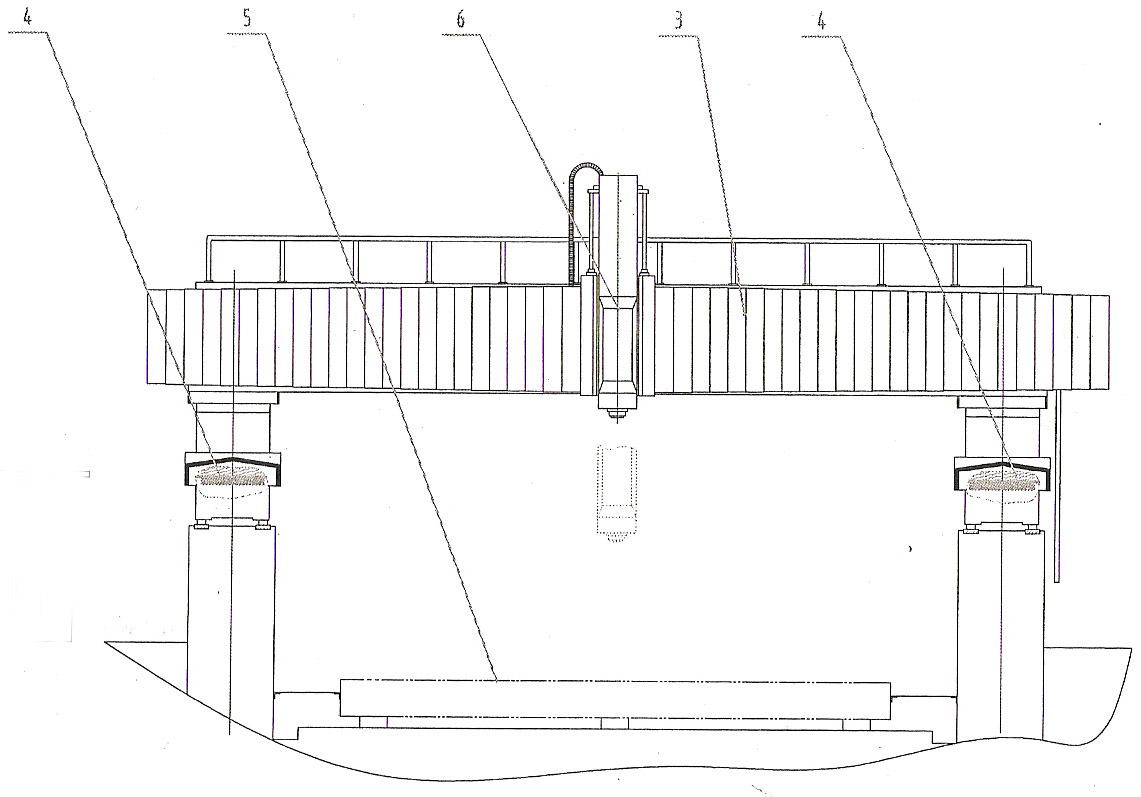

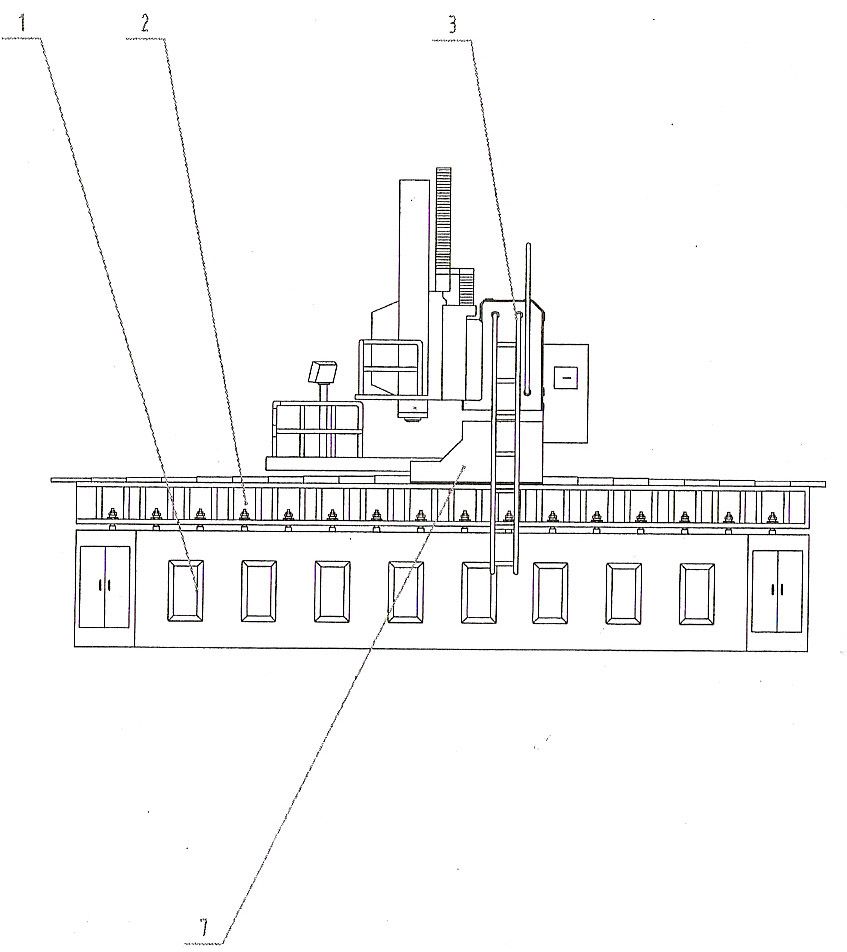

[0011] A direct-drive beam mobile CNC gantry boring and milling machine, including a frame 1, a rigid frame composed of a double bed body 2, a beam 3, a beam base 7, and a fixed worktable 5. The guide rail of the double bed body can be installed along the X axis The moving beam 3 is equipped with a ram 6 that can move along the Y axis and Z axis, and the tool is clamped on the ram; the driving mechanism for the X axis movement of the beam is a linear motor (linear motor) 4 that realizes direct drive.

[0012] The X-axis movement, Y-axis movement and Z-axis movement implement closed-loop numerical control with magnetic scale feedback.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com