Vacuum induction smelting furnace

A technology of vacuum induction melting and melting chamber, which is applied in the direction of furnace, crucible furnace, furnace type, etc. It can solve the problems of difficult vacuuming, large furnace cavity volume, complex furnace structure, etc., and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0019] The technical scheme of concrete implementation of the present invention is:

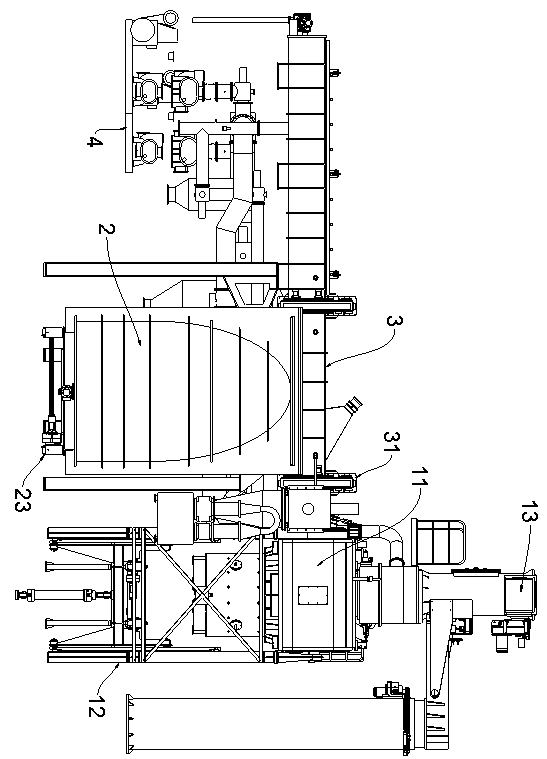

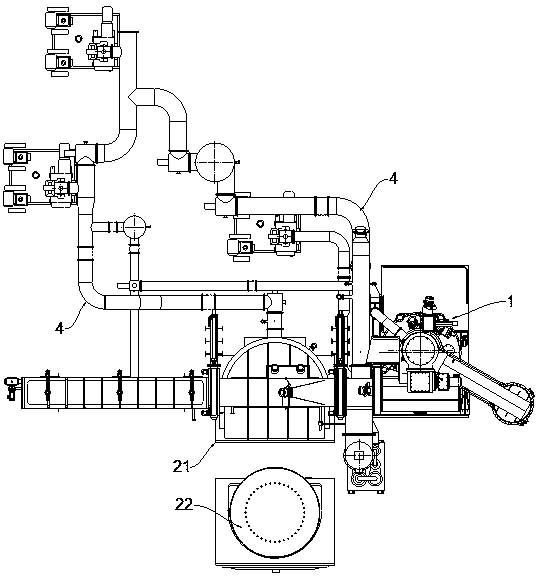

[0020] Such as figure 1 and figure 2 As shown, a vacuum induction melting furnace includes a melting chamber 1 and an ingot casting chamber 2 communicated through a flow channel 3;

[0021] The smelting chamber 1 includes a furnace body 11 supported by a furnace frame 12. A crucible is provided in the furnace body 11. The crucible is equipped with an induction coil. One end of the flow channel 3 extends into the smelting chamber 1. The crucible is located in the flow channel 3. Above, the crucible is also equipped with an overturn drive mechanism that drives it to pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com