Side bolt drilling machine and side bolt drilling carriage with same

A technology for assisting bolts and drilling rigs, which is applied to the field of underground support in coal mines, can solve the problems of low degree of mechanization of single-type bolting, low efficiency of single-type bolting, low supporting efficiency, etc., and achieves convenient installation of anchors. Rod, compact structure, high drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The gang-bolt drilling rig provided by the present invention is a mechanized rock-bolt support equipment that can be matched with the excavation equipment. When working, it follows the excavation equipment and advances synchronously to complete the automatic support operation of the gang-bolt, realizing simultaneous excavation and simultaneous drilling. Anchor, excavation and anchor parallel operation, thus greatly improving the excavation efficiency and excavation footage.

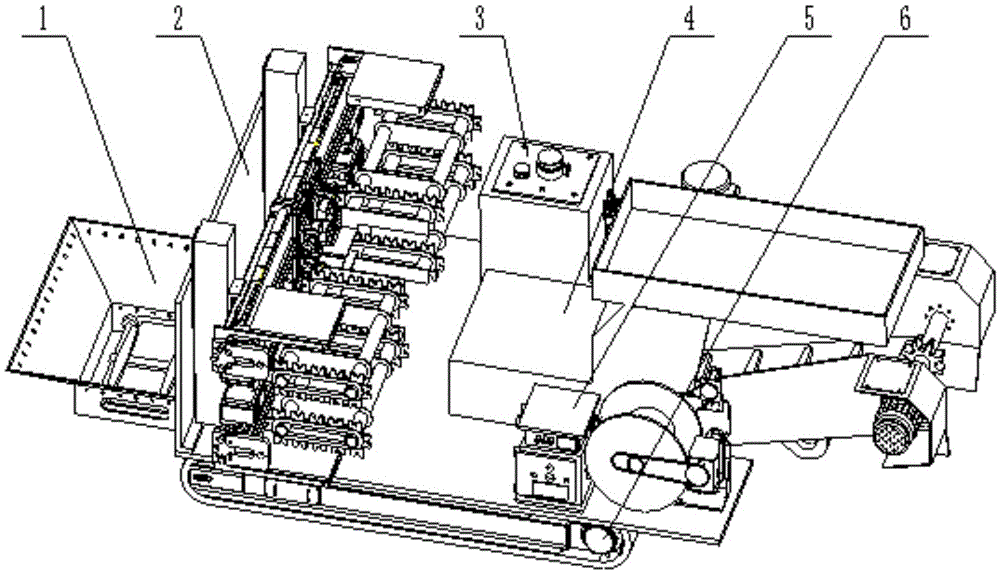

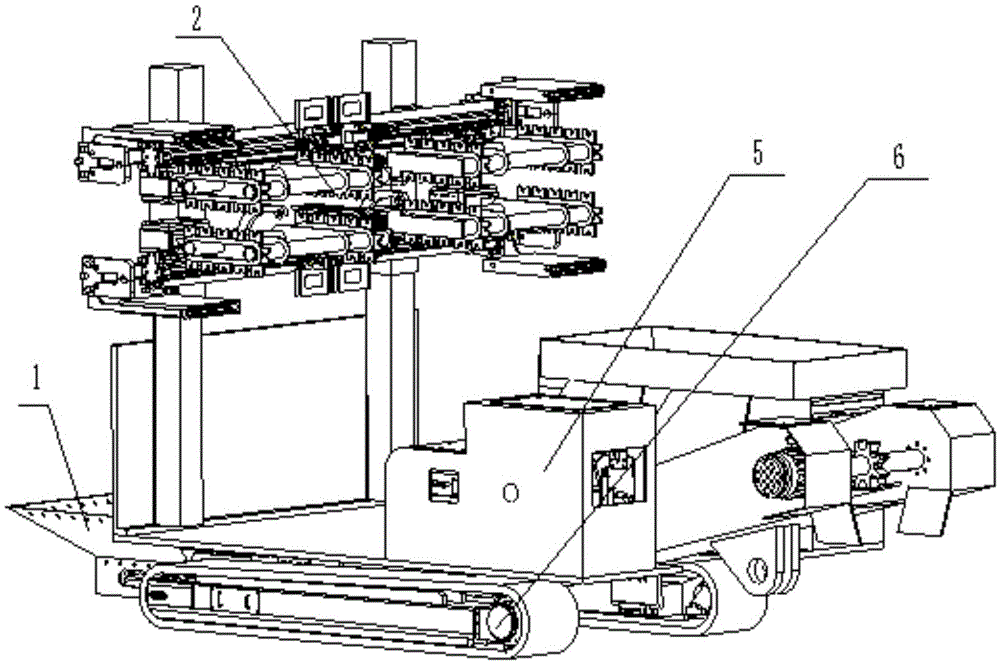

[0048] Refer to attached figure 1 and 2 As shown, the rock bolter of the present invention includes a self-propelled mechanism 6 , a body part 4 , a boom mechanism 2 , a control mechanism 5 , a transfer part 1 and an electrical and hydraulic system 3 .

[0049] The self-propelled mechanism 6 is a crawler-type traveling mechanism, which is located at the bottom of the drilling rig, and includes a tightening oil cylinder, a traveling motor and a speed reducer. The tension of the track can be adjusted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com