Multi-section concrete pole automatic assembly and production device and assembly method thereof

An automatic assembly, cement pole technology, applied in the field of pole production, can solve problems such as low production efficiency, achieve the effect of improving quality and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

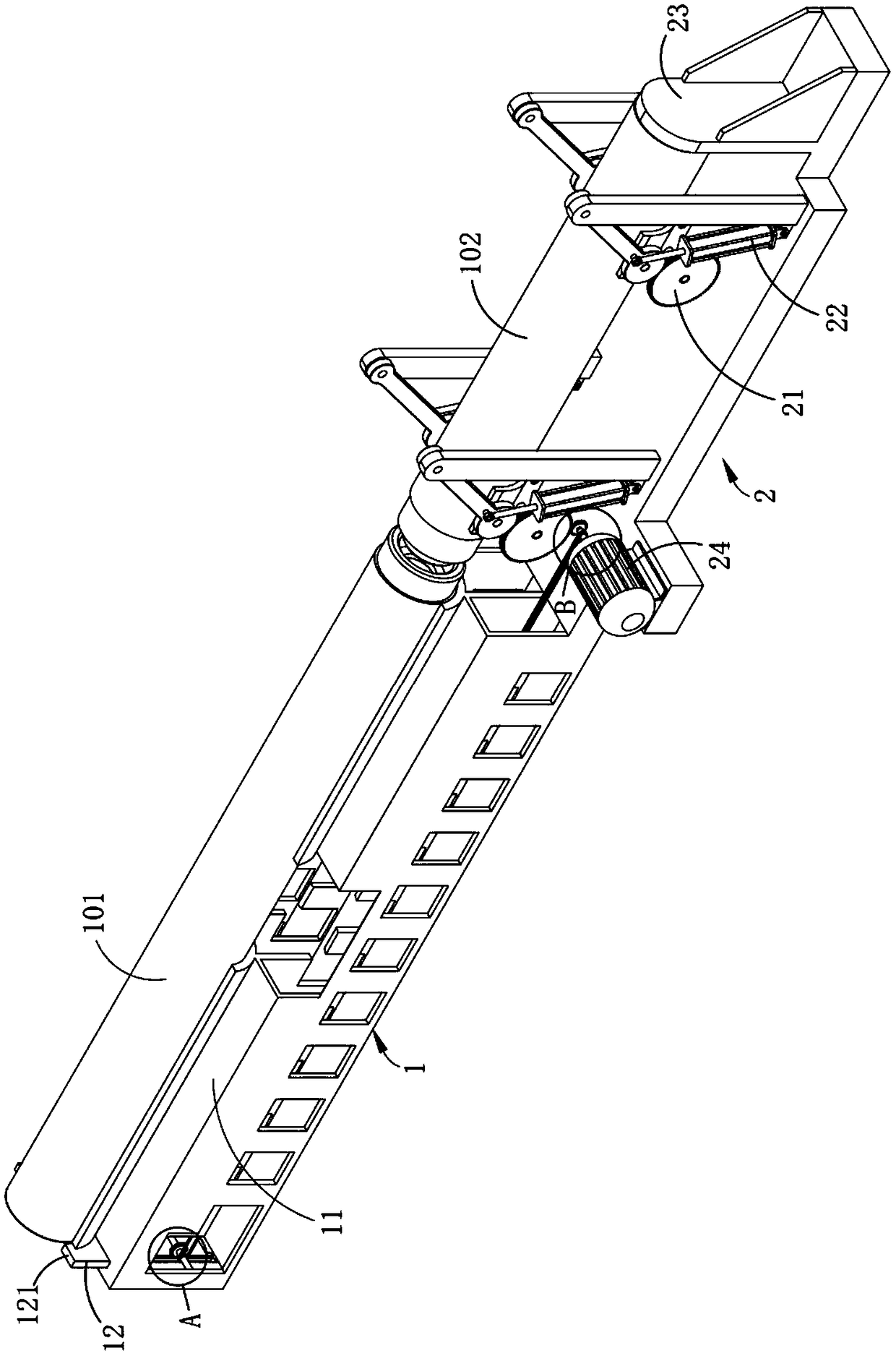

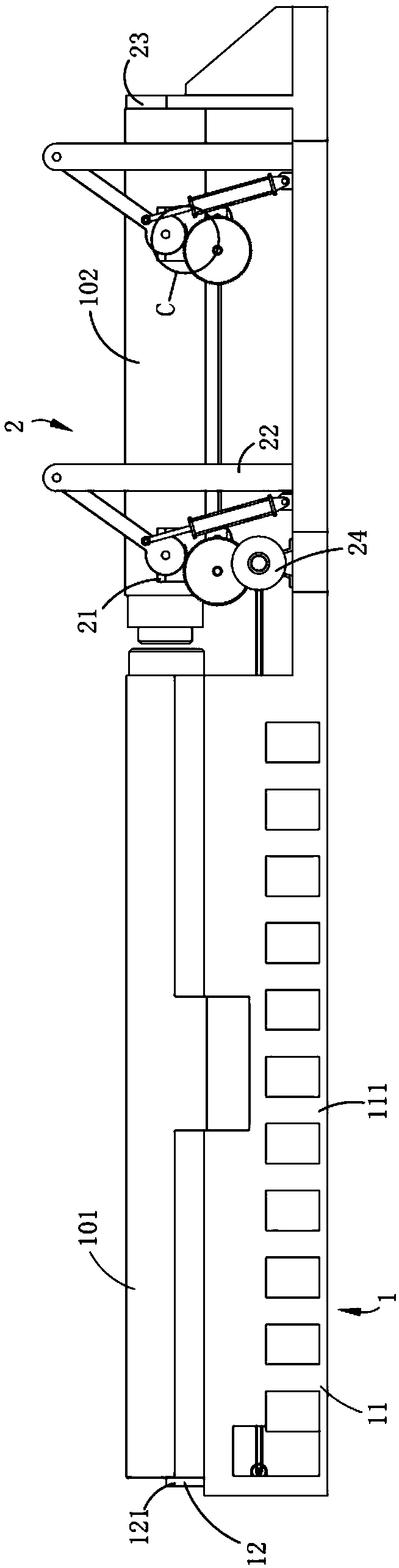

[0040] Such as figure 1 and 2 As shown, a multi-section cement pole automatic assembly production device includes:

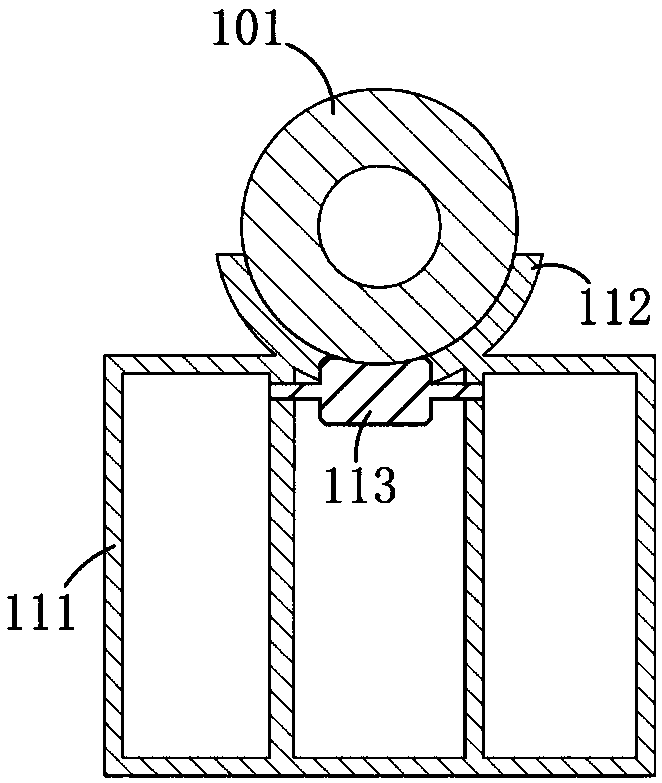

[0041] A reference platform 1, the reference platform 1 is provided with a placement assembly 11 for placing the main body 101 of the utility pole 10, and a positioning assembly 12 provided on the placement assembly 11 for the end limit of the main body 101; in this embodiment Among them, the placing component 11 is set horizontally, and after the main body 101 is placed on it, the positioning component 12 positi...

Embodiment 2

[0049] Such as figure 2 , 6 , 7, 8 and 9, wherein the same or corresponding parts as in the first embodiment adopt the corresponding reference numerals with the first embodiment, for the sake of simplicity, only the differences from the first embodiment are described below; the second embodiment The difference from Embodiment 1 is that the transmission assembly 22 also includes an adjustment part 224 arranged on the swing arm 222 and intermittently connected to the rotating wheel 213. The adjustment part 224 is configured as a transmission tooth structure. And it is arranged coaxially with the placement groove 211; in this embodiment, the rotating wheel 213 is provided with a gear structure, and the adjustment part 224 and the rotating wheel 213 are adapted to be arranged. When the driving member 223 drives the placement groove 211 to be installed at the highest When the body 102 is placed, the adjustment part 224 is separated from the rotating wheel 213, and the rotating ro...

Embodiment 3

[0052] Combined with the accompanying drawings Figure 10 A production method for automatic assembly of multi-section cement poles in this embodiment is described.

[0053] A production method for automatic assembly of multi-section cement poles, comprising the following steps:

[0054] (a) The main body is placed, and the main body 101 is placed horizontally in the limiting groove 112 on the placement component 11, and its end is limited by the positioning component 12;

[0055] (b) fine-tuning of the installation body, after the installation body 102 is placed in the placement groove 211 on the support assembly 21, the driver 223 on the transmission assembly 22 drives the horizontal movement down in a telescopic manner, and the adjustment part 224 drives the rotation The roller 212 drives the installation body 102 to move horizontally in a rotational manner, and at the same time, it is blocked by the limit assembly 23 to realize the position adjustment of the installation b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com