Automatic dip-coating production method of concave fixture

A production method and concave technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of low production efficiency of dipping, achieve the effect of improving efficiency, reducing production cost, and canceling manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

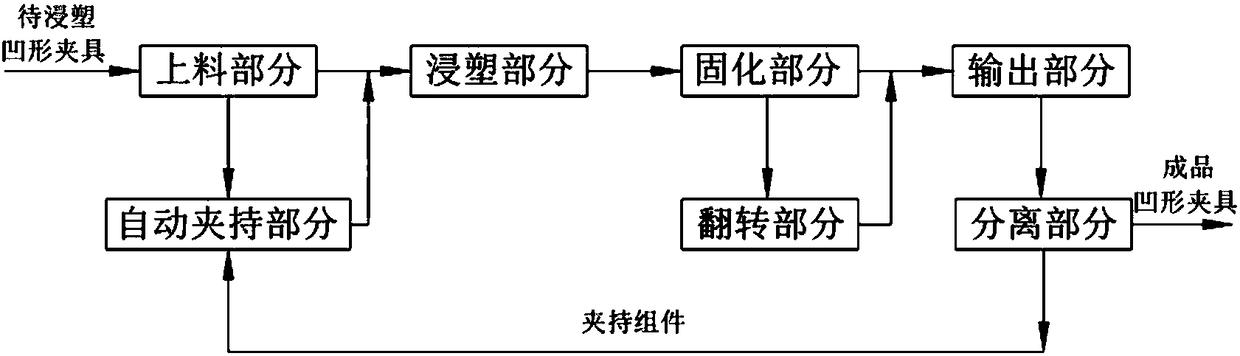

[0043] Combined with the accompanying drawings in the manual figure 1 A production method of automatic dipping of concave fixtures in this embodiment is described.

[0044] An automatic dipping production method for concave fixtures, comprising the following parts:

[0045] (a) Feeding part, the concave fixture 10 and the clamping assembly 22 to be impregnated are manually placed on the limit assembly 21 and the guide rod 24, and the transfer assembly 31 on the transfer mechanism 3 is driven and clamped Component 22 carries out...

Embodiment 2

[0054] Wherein, the same or corresponding parts as those in the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below; the difference between the second embodiment and the first embodiment is that : the step (c) also includes an overturning part, and the bevel gear 313 on the transfer assembly 31 is driven by the rotation assembly 32 on the transfer mechanism 3 to rotate with the fan-shaped bevel gear 314 on the transfer assembly 31 with intermittent transmission The method is connected to realize the rotation of the concave fixture 10 after dipping by 180°; through the transmission of the fan-shaped bevel gear and the bevel gear fixedly set, the dipping unit after dipping can be rotated by 180°, so as to avoid that the dipping liquid cannot solidify in time after the liquid is macerated And the dripping problem that appears.

[0055] Further, after the...

Embodiment 3

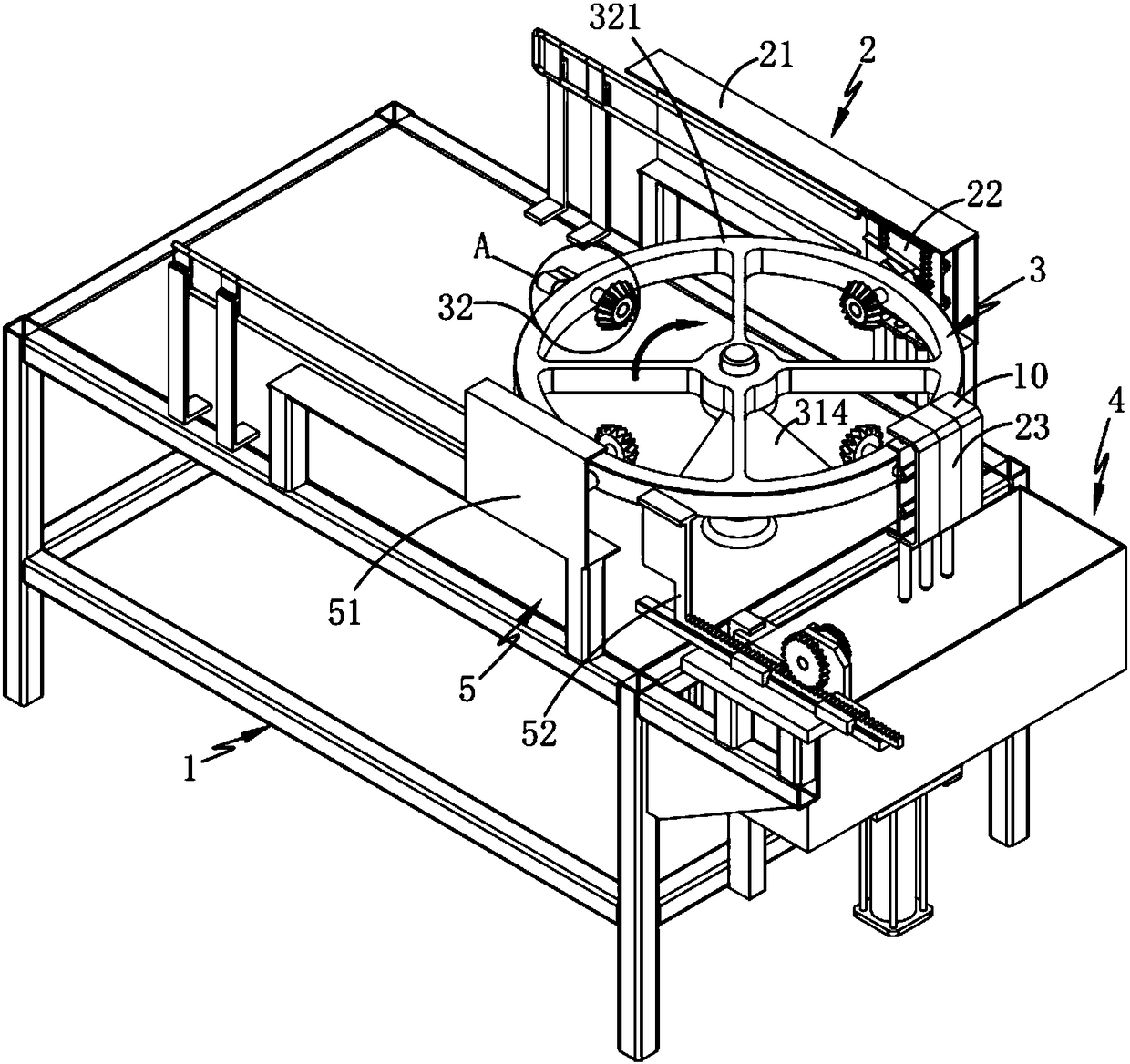

[0059] Combined with the manual Figure 2-14 Describe an automatic dipping production equipment for concave fixtures in this embodiment.

[0060] Such as figure 2 , 3 , 4 and 5, a concave fixture automatic dipping production equipment, including frame 1, also includes:

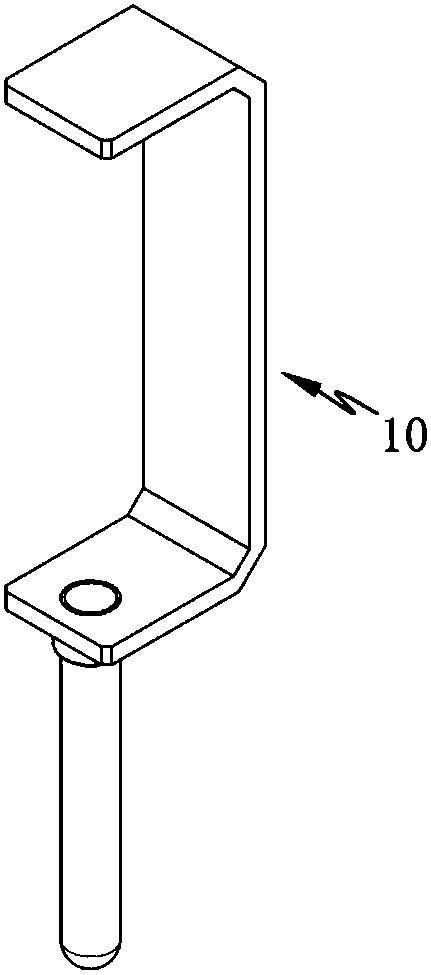

[0061] The limit mechanism 2, the limit mechanism 2 is arranged on the frame 1, which includes a limit assembly 21 for the positioning and transmission of the concave fixture 10 and a clamping assembly 22 for clamping the concave fixture 10, the concave Shaped clamp 10 is clamped by the clamping assembly 22, and both of them form a dipping unit 23; in this embodiment, as an implementation, the clamping assembly 22 can clamp three concave clamps 10 at a time Transfer; wherein as a preferred mode, the limit assembly 21 is provided with a groove structure adapted to the shape of the concave fixture 10, and the lower part of the groove cooperates with the part to be dipped on the concave fixture 10 to realize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com