A jig transmission mechanism for automatic dipping production

A technology of conveying mechanism and jig, which is applied to devices and coatings for coating liquid on the surface, can solve problems such as low production efficiency of dip molding, and achieve the effect of solving low production efficiency, ensuring production stability and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

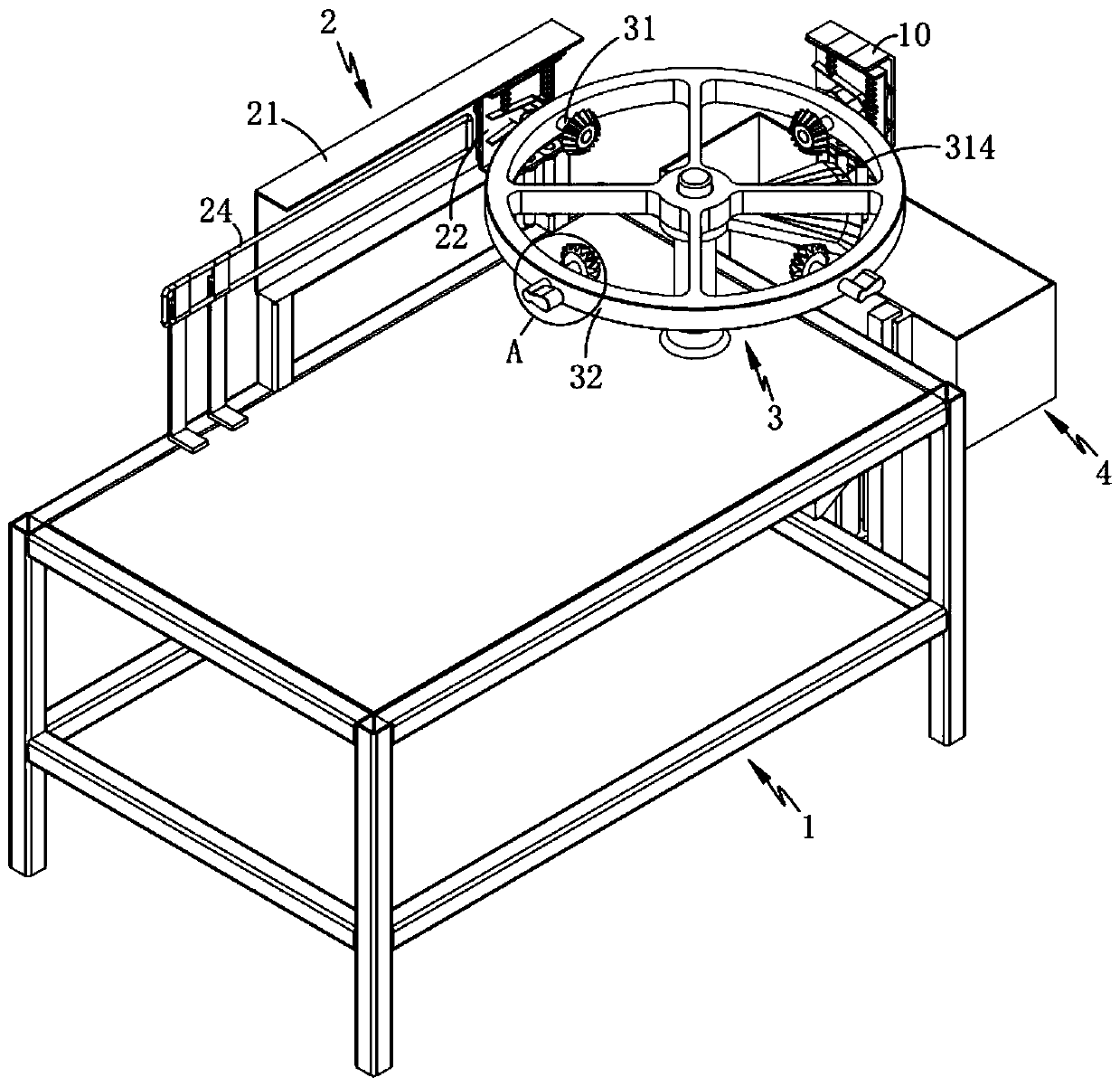

[0034] Such as figure 1 , 2 , 3 and 4, a clamp transmission mechanism for automatic dipping production, including a frame 1, also includes:

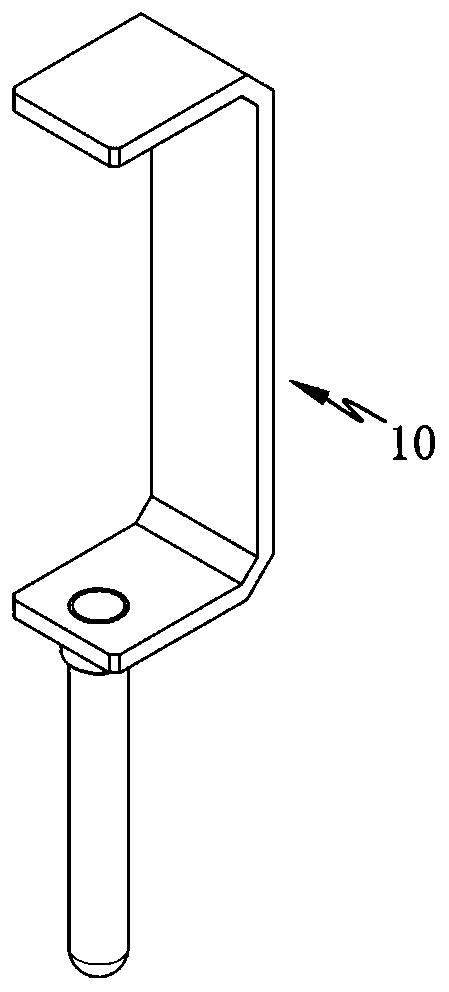

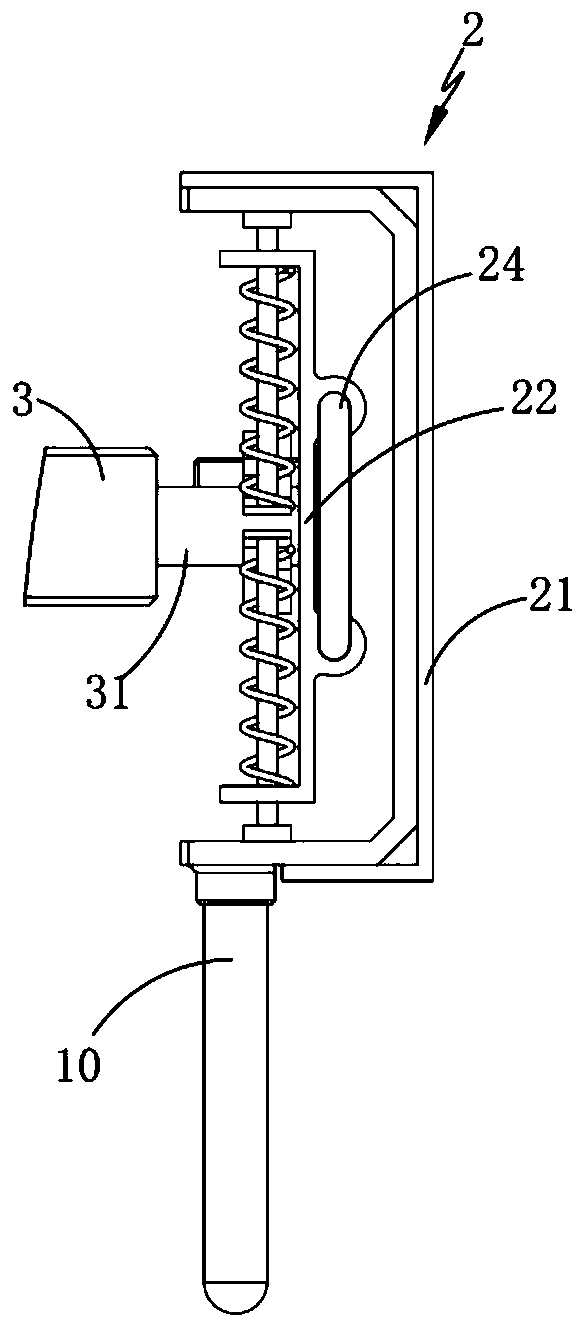

[0035] The limiting mechanism 2, the limiting mechanism 2 includes a limiting component 21 and a clamping component 22, after the concave clamp 10 in the limiting component 21 is positioned and clamped by the clamping component 22, the two are transferred synchronously ; In this embodiment, as an implementation mode, the clamping assembly 22 can clamp and transfer three concave clamps 10 ...

Embodiment 2

[0045] Such as figure 1 , 4 and 7, wherein the same or corresponding parts as in the first embodiment adopt the corresponding reference numerals with the first embodiment, for the sake of simplicity, only the difference from the first embodiment is described below; the second embodiment is different from the first embodiment The difference is that: the transfer assembly 31 includes a rotating shaft 311, a pretensioning part 312 fixed at one end of the rotating shaft 311, a bevel gear 313 at the other end of the rotating shaft 311, and a bevel gear 313 fixed at the frame 1 The fan-shaped bevel gear 314 on the top and intermittently meshed with the bevel gear 313, the pre-tightening part 312 is set on a slant block with the same inclination angle as the guide plate 2223, and it is located on the outside of the rotating assembly 32. In the embodiment, the fan-shaped bevel gear 314 is located in the rear section of the dipping station, and through the transmission of the fixed fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com