Novel arc-shaped railway sleeper structure of shield tunneling machine

A shield machine, arc technology, applied in the field of the arc sleeper structure of the new shield machine, can solve the problems of cumbersome operation process, and achieve the effect of improving efficiency and simplifying operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

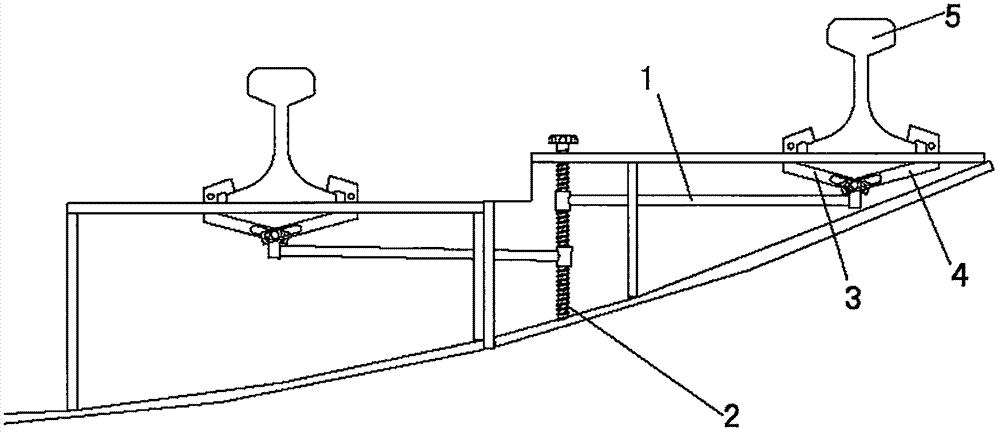

[0011] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the sleeper realizes fast clamping of the rail through clamps. When in use, rotate the screw to move the two connecting rods upwards, driving the two jaws of the jaw group to separate to a sufficient distance in the opposite direction, and then place the rail on the sleeper plane to ensure that the distance between the rails meets the requirements, and then reverse Rotate the screw to drive the connecting rod to move down, so that the jaws can grasp the rail to achieve fast clamping and improve efficiency.

[0013] The sleepers of this structure are connected by hinges, the original three-stage structure is integrated into a whole, and a linkage clamping device is used to realize one-time clamping of the rail, which simplifies operation and improves efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com