Pre-embedded hole drill carriage for coal mine

A technology of pre-buried holes and drilling rigs, which is applied to drilling equipment, earthwork drilling, drilling equipment and methods, etc. It can solve the problems of high labor intensity, difficult construction operations, and low labor efficiency, and achieve simplified rigging. Bridge design, improving construction efficiency, and facilitating operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

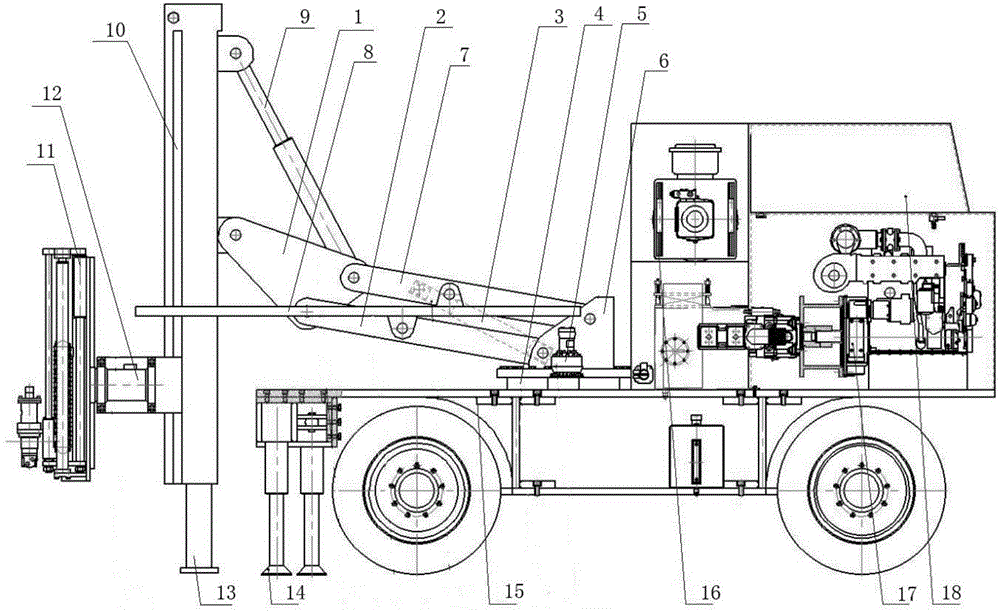

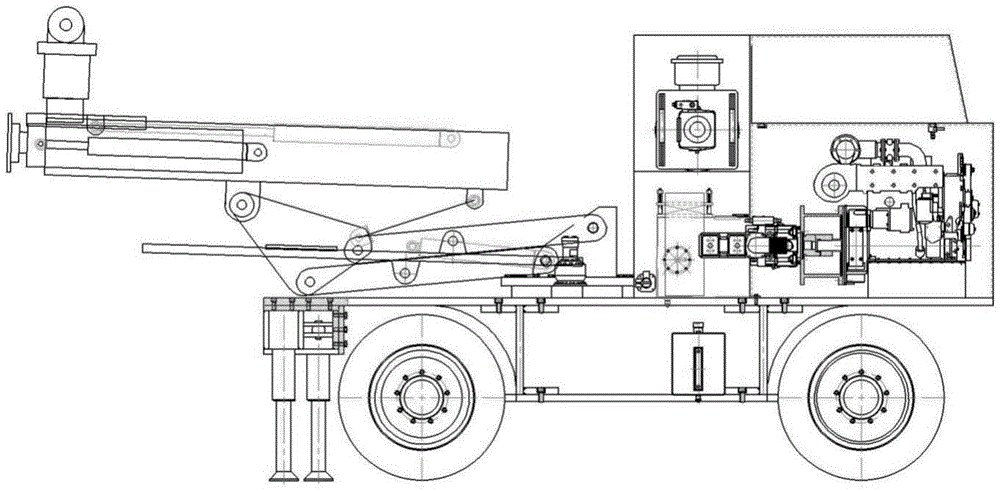

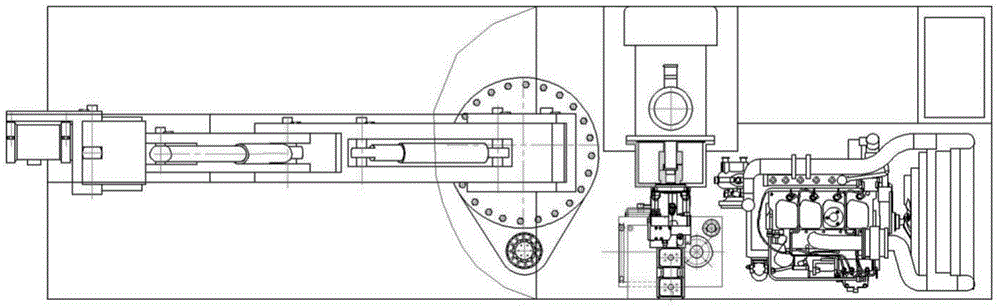

[0027] see Figure 1-4 As shown, a pre-buried hole drilling rig for coal mines includes a drilling mechanism, a walking chassis 15 and a driving control part. , the lifting device installed on the rotary device and the drilling device 11 slidably installed on the lifting device.

[0028] More specifically, the driving control part includes an explosion-proof motor unit 16 , an explosion-proof engine unit 17 and a closed cab 18 . The drilling device 11 realizes position change and drilling work under the action of the lifting device and the sliding parts.

[0029] The lifting device adopts a four-link structure composed of a connecting rod mounting seat 6, a first connecting rod 2, a second connecting rod 7 and a triangular connecting rod connecting block 1, and all parts of the four-link structure are connected by pins. Wherein: the connecting rod mounting seat 6 is installed on the slewing device, the first connecting rod 2 and the second connecting rod 7 are parallel, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com