Machining method of ultra-thin graphite sample

A processing method and graphite technology, applied in the processing field of ultra-thin graphite samples, can solve the problems of easy deformation and rolling of graphite samples, low production speed of ultra-thin graphite samples, difficult quality control, etc., and achieve the overall temperature and grinding quality. 、Ensure the surface flatness and grinding quality, and improve the effect of grinding flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

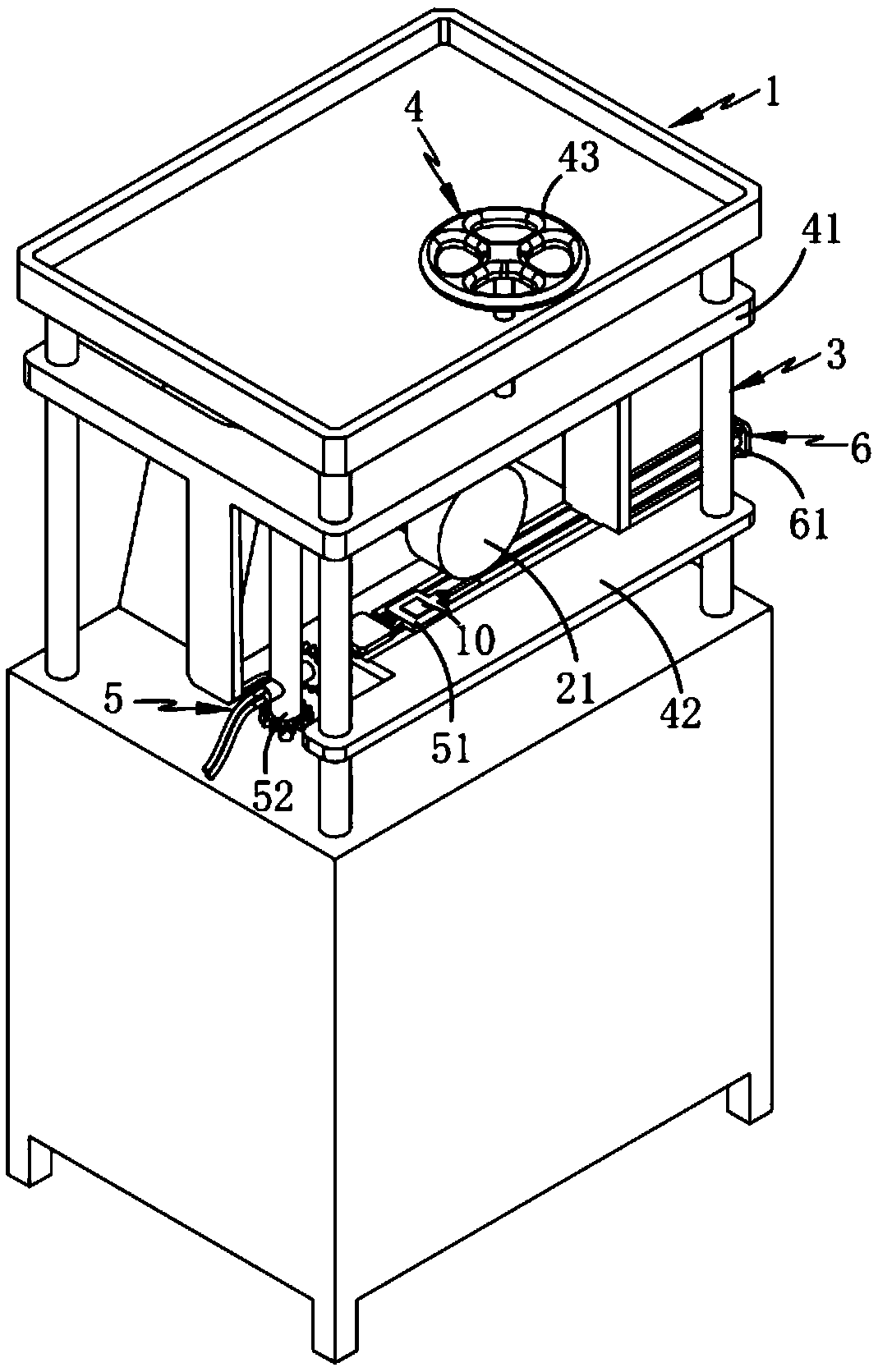

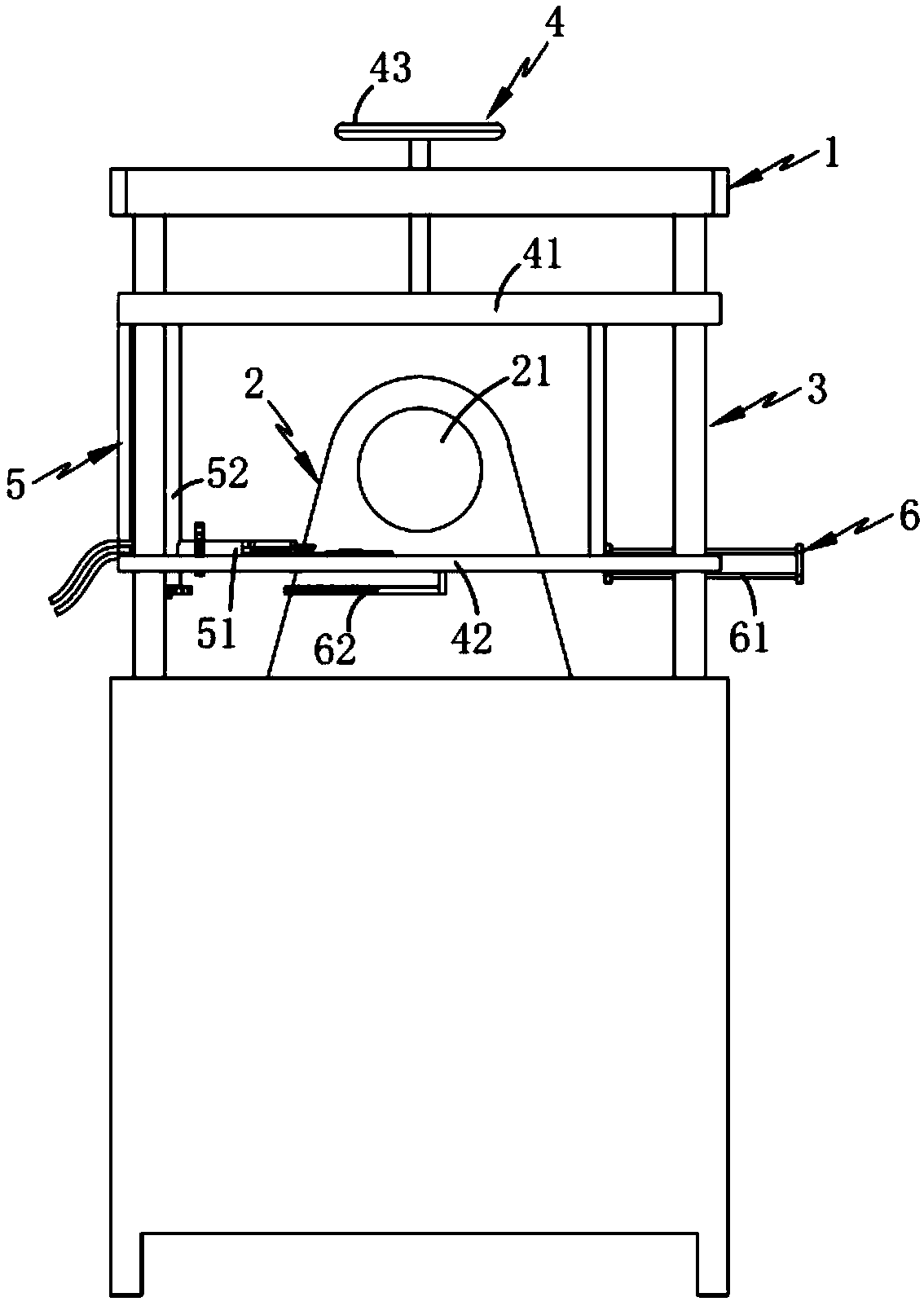

[0040] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

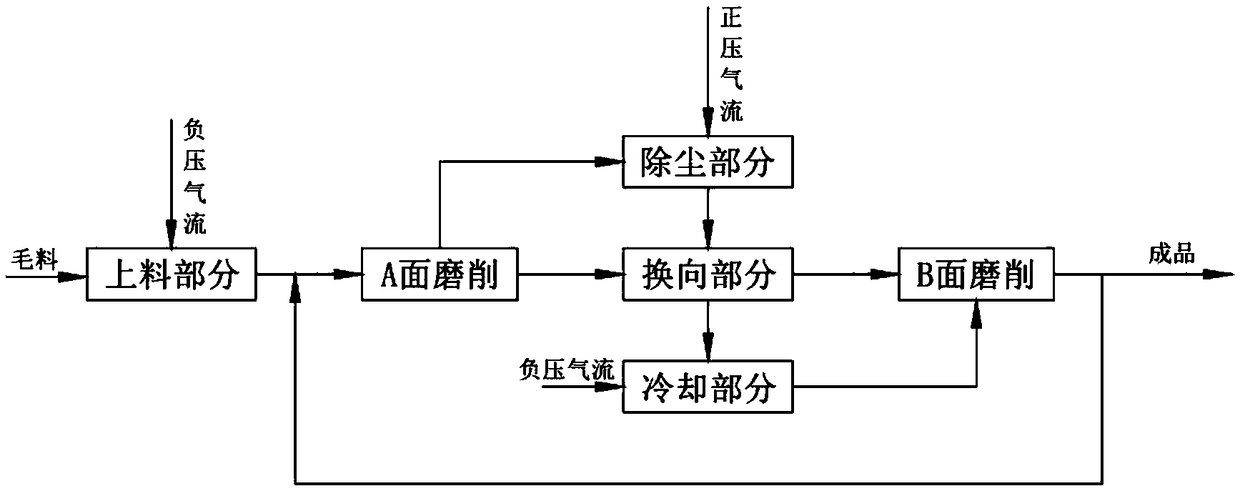

[0041] According to the drawings in the manual figure 1 Describe the processing method of an ultrathin graphite sample in this example.

[0042] A processing method for an ultrathin graphite sample, comprising the following steps:

[0043] (a) For the feeding part, the wool is placed in the positioning cavity 5142 on the positioning part B514 in an inlaid manner, and then fixed by negative pressure adsorption;

[0044] (b) Grinding of surface A, after step (a), drive the positioning part A513 through the reciprocating motion mo...

Embodiment 2

[0054] Wherein, the same or corresponding parts as those in the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below; the difference between the second embodiment and the first embodiment is that : The step (c) also includes a dust removal part, which is arranged on the reversing assembly 52 by rotating the positive pressure air pipe and the negative pressure air pipe which are arranged up and down and respectively contain the positive pressure air flow and the negative pressure air flow, through the positioning part A513 and the positioning part B514 Connected with the positive pressure air tube and the negative pressure air tube respectively, the upper surface of the graphite sample 10 adsorbed by the positive pressure airflow in the positioning part A513 below it and adsorbed on the positioning part B514 is cleaned by blowing dust and at the same time...

Embodiment 3

[0057] (a) For the feeding part, put the wool material with a thickness of 1±0.05mm, length×width: 10×10mm into the positioning cavity 5142 with a specification of length×width: 10×10mm and a depth of 0.4mm on the positioning part B514. Fix it by negative pressure adsorption;

[0058] (b) A surface grinding, after step (a), the graphite sample 10 on the positioning part A513 is driven by the drive assembly 61 on the translation mechanism 6 to perform a reciprocating motion, and the graphite sample 10 is reciprocating with the grinding wheel 21 contact, the surface A of the graphite sample 10 is subjected to light grinding treatment;

[0059] (c) Reversing part, after the step (b), the positioning part B514 is pushed to the reversing station by the drive assembly 61, and the positive pressure air flow in the positioning part A513 blows and removes dust on the A surface of the graphite sample 10 , the transmission assembly 62 on the translation mechanism 6 drives the reversing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com