Grooving machine

A technology of slotting machine and cutting mechanism, applied in cutting machinery, slitting machinery, driving device, etc., can solve the problems of harsh working environment, high labor intensity, slow construction speed, etc., to reduce labor intensity and high mechanical efficiency. , Improve the effect of slotting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The slotting machine of the present invention can realize the excavation of the two sides and the top groove in one positioning in the coal mine underground roadway, realize the mechanization of the slotting operation, reduce the labor intensity, reduce the number of operators, and improve the efficiency and safety of the slotting operation coefficient. Of course, this embodiment takes the slotting machine applied to the slotting operation of the coal mine underground roadway as an example, which cannot be understood as any limitation on the slotting machine of the present invention.

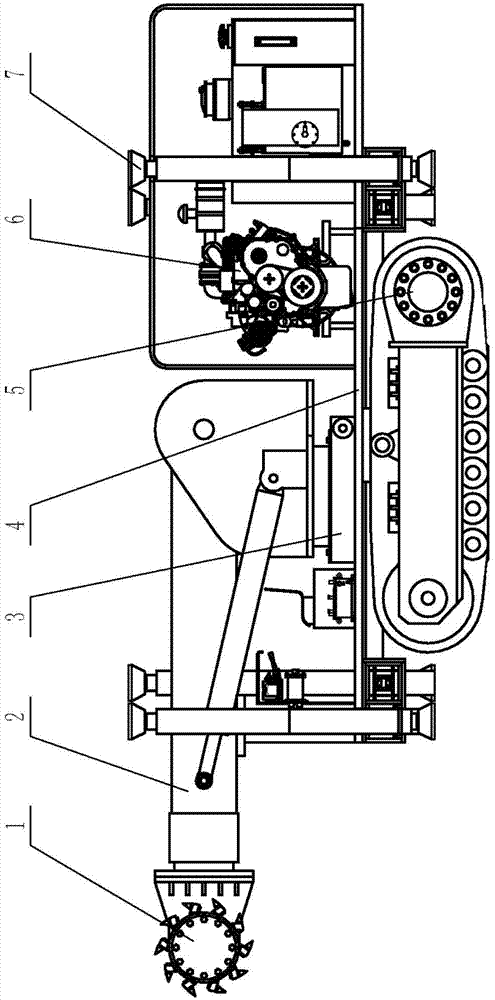

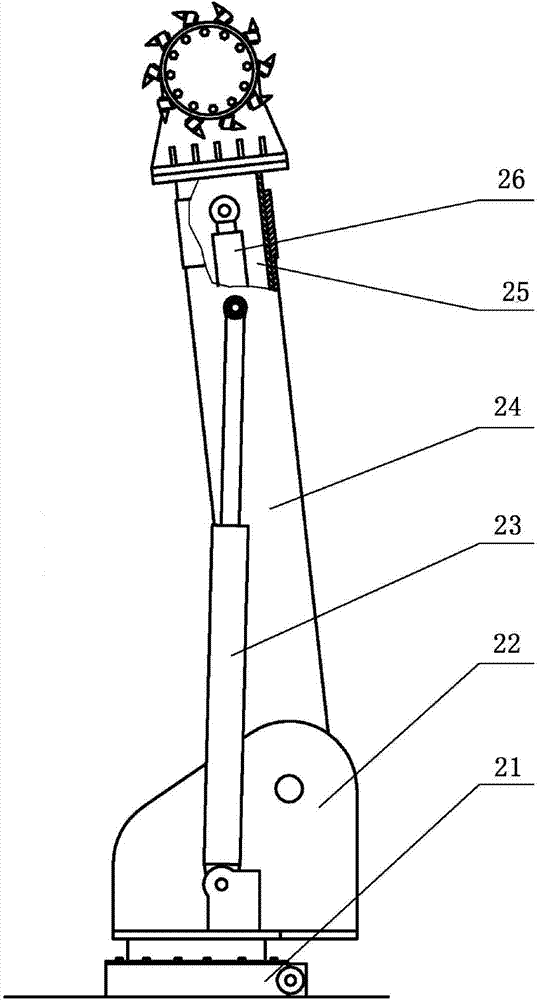

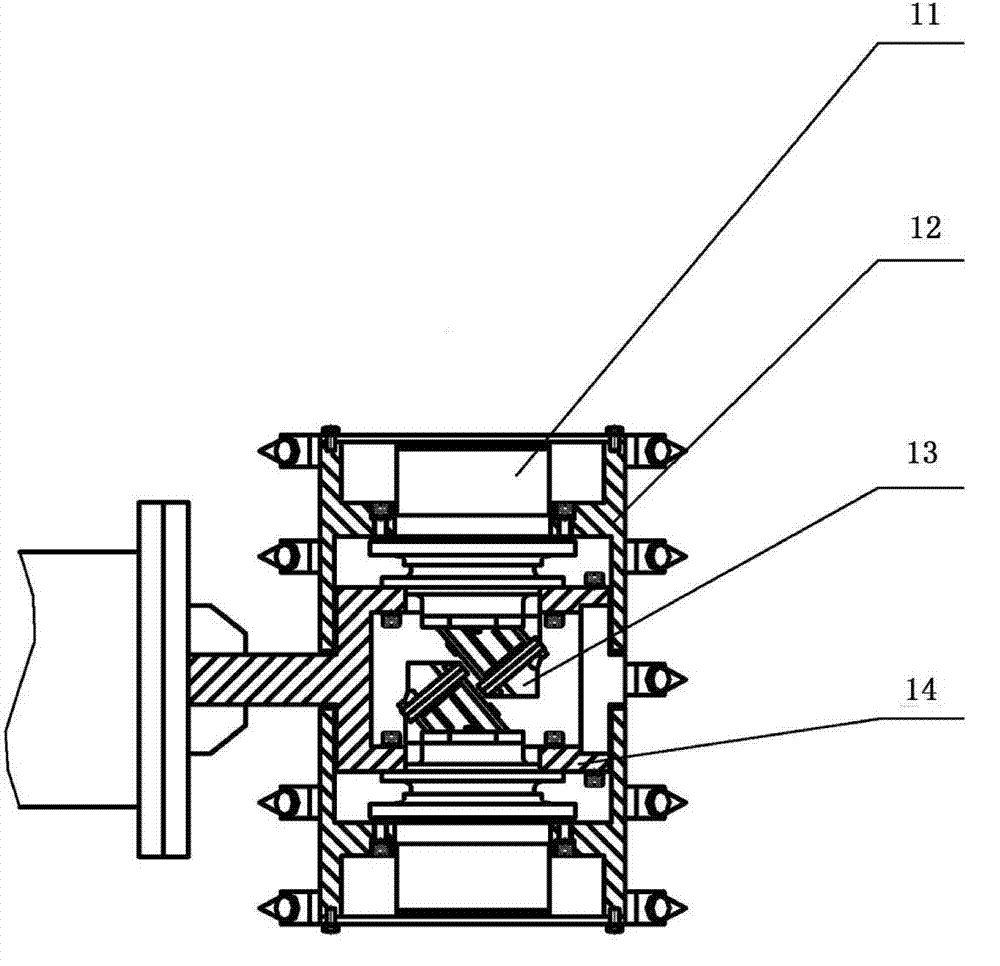

[0034] Refer to attached figure 1 As shown, a slotting machine for connecting lanes of the present invention includes a self-propelled mechanism 5, an installation platform 4, a working arm rotating mechanism 3, a working arm mechanism 2, a cutting mechanism 1, a vehicle stabilizing leg mechanism 7, a pump station part 6, Electrical system and hydraulic system.

[0035] The self-propell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com