Microbiological fuel cell composite material anode and its manufacturing method

A composite material and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low removal rate of organic pollutants, low power generation capacity of microbial fuel cells, etc., to improve the anode electron transfer rate, increase the Electron transfer rate, effect of increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

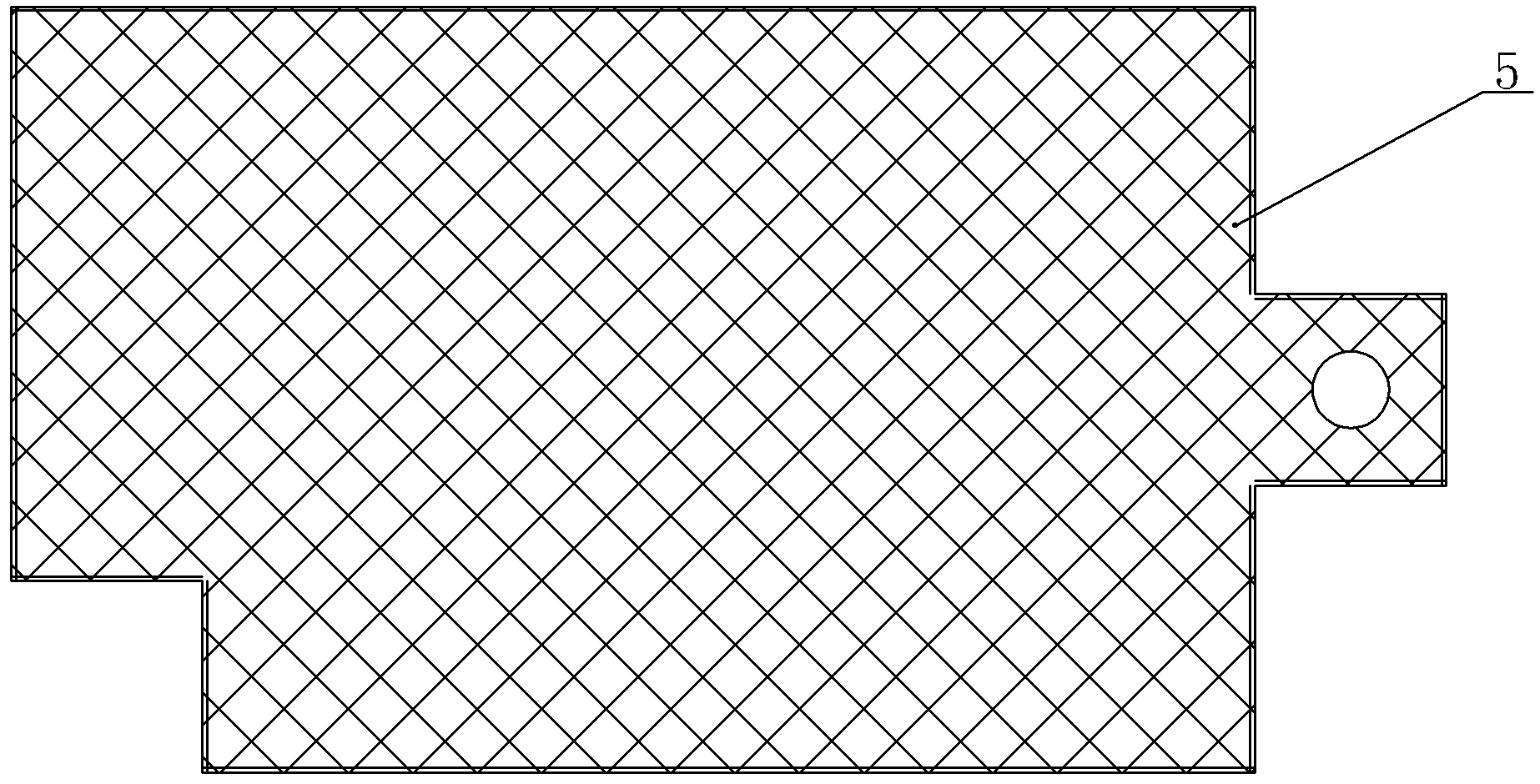

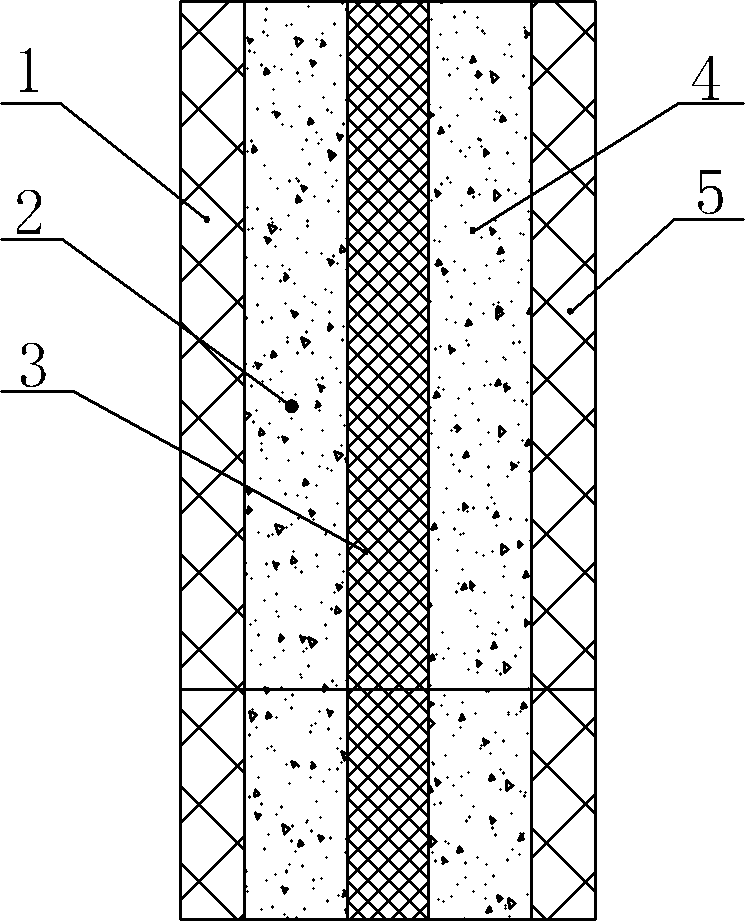

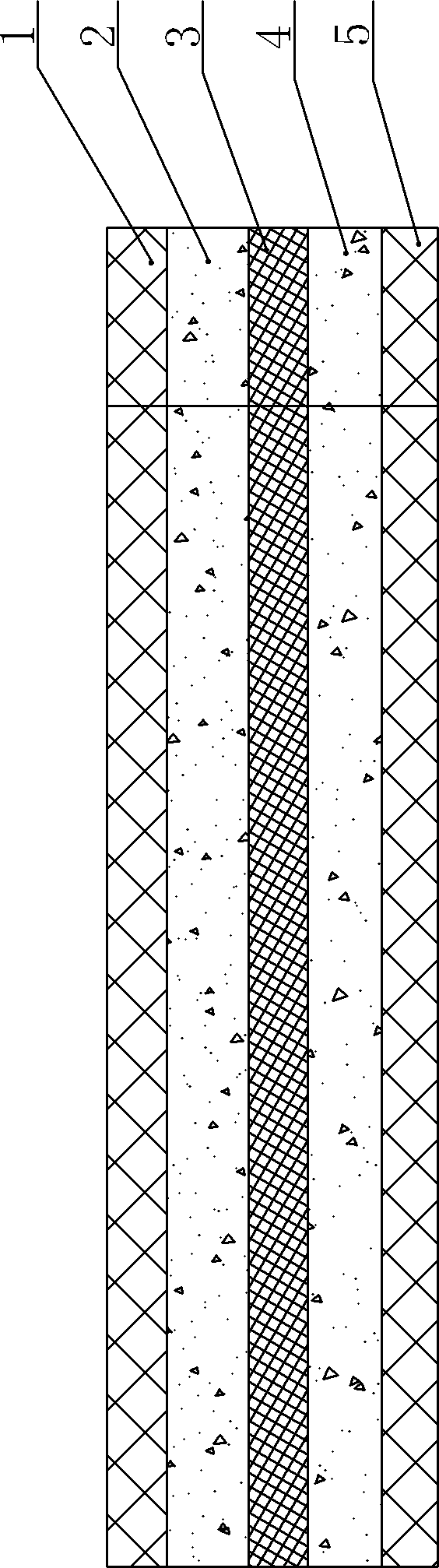

[0019] Specific implementation mode one: combine Figure 1 ~ Figure 3 To illustrate this embodiment, a microbial fuel cell composite material anode of this embodiment is a pressed product, and the anode includes a first wire mesh layer 1, a first non-metallic plate layer 2, a second wire mesh layer 3, The second non-metal plate layer 4 and the third metal mesh layer 5, the second non-metal plate layer 2 is located between the first metal mesh layer 1 and the second metal mesh layer 3, the second non-metal plate layer 4 is set Between the second wire mesh layer 3 and the third wire mesh layer 5, the wires of the first wire mesh layer 1, the second wire mesh layer 3 and the third wire mesh layer 5 are all Nitriding and carburizing composite layers, the materials of the first non-metallic plate layer 4 and the second non-metallic plate layer 5 are carbon-based materials, and the metal mesh of the second metal mesh layer 3 The aperture is smaller than the aperture of the wire mes...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 2 and image 3 To illustrate this embodiment, the second wire mesh layer 3 described in this embodiment is one of a titanium wire mesh layer, a nickel metal mesh layer, a 316 stainless steel wire mesh layer or a 316L stainless steel wire mesh layer. Such setting can effectively improve the anti-corrosion ability of the product, and is suitable for water bodies in different water areas. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination figure 2 and image 3 Describe this embodiment, the wire mesh of the second wire mesh layer 3 described in this embodiment is a square hole mesh, the wire diameter of the metal wire of the second wire mesh layer 3 is 0.5~5.0mm, the second metal wire The aperture of the wire mesh of the mesh layer 3 is 3-30mm. Such setting meets the design requirements. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com