Copper wire painting equipment for horizontal high-speed enamelling machine

An enameling machine and painting technology, applied in the direction of insulating conductors/cables, etc., can solve the problems of clogging the lacquer channel, too little copper wire coating, and no paint in the lacquer channel, so as to eliminate instantaneous blockage and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] For ease of understanding, one of the specific implementation structures of the present invention is cited here, and its workflow is described as follows:

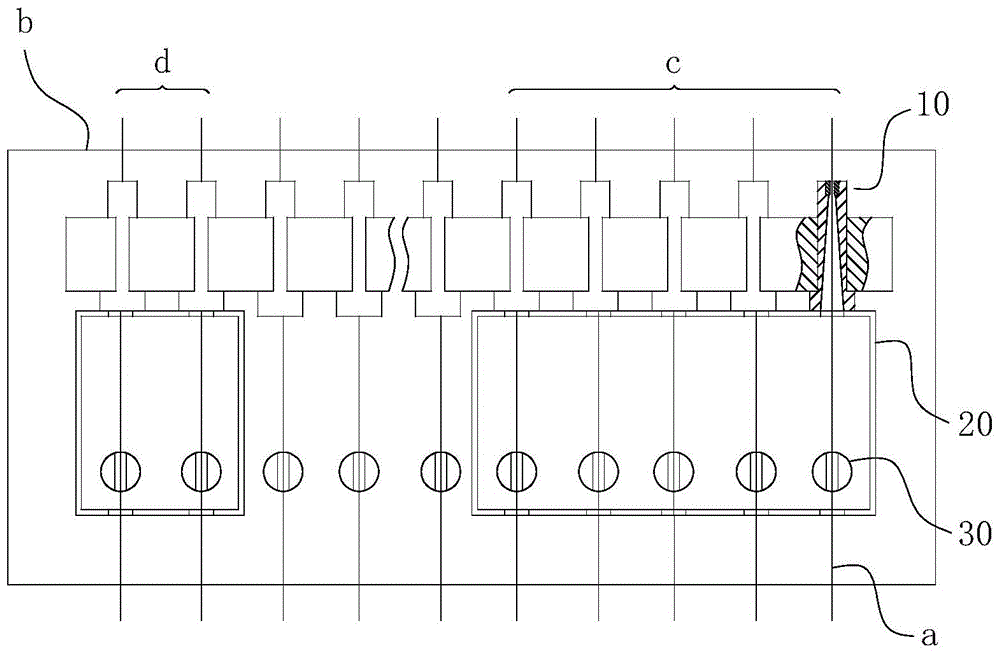

[0029] Figure 5 Among them, the solid line arrow is the traveling direction of the copper wire a, and the dotted line arrow is the paint inlet direction of the paint outlet 30; Figure 2-5 Shown; the layout of the primer painting area c and the surface paint painting area d is as follows figure 1 shown.

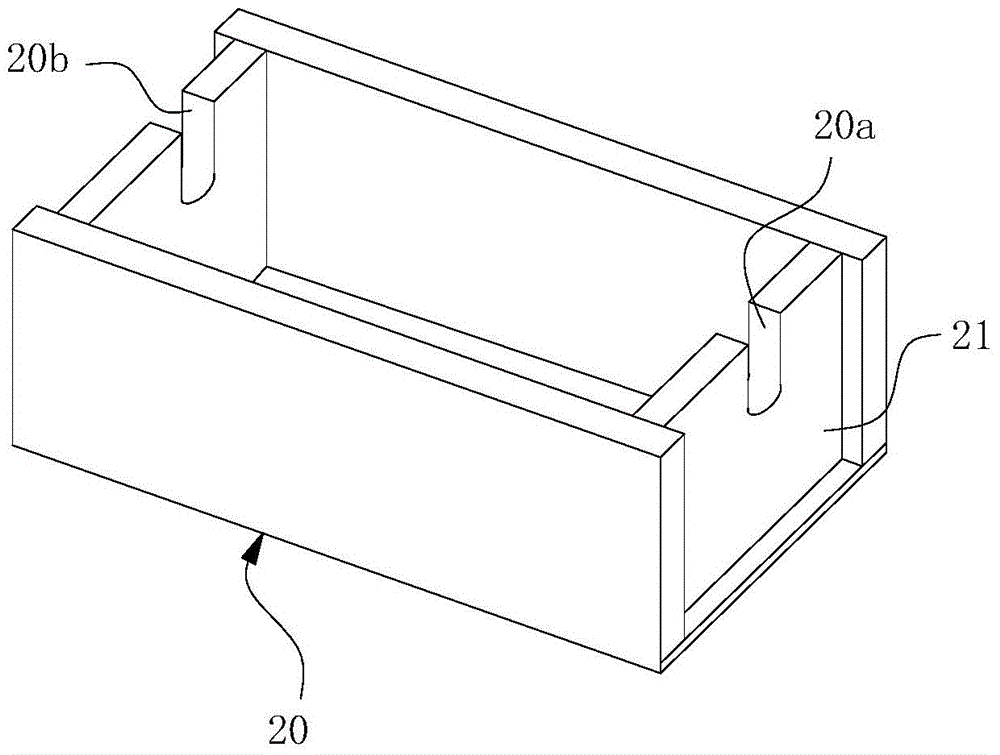

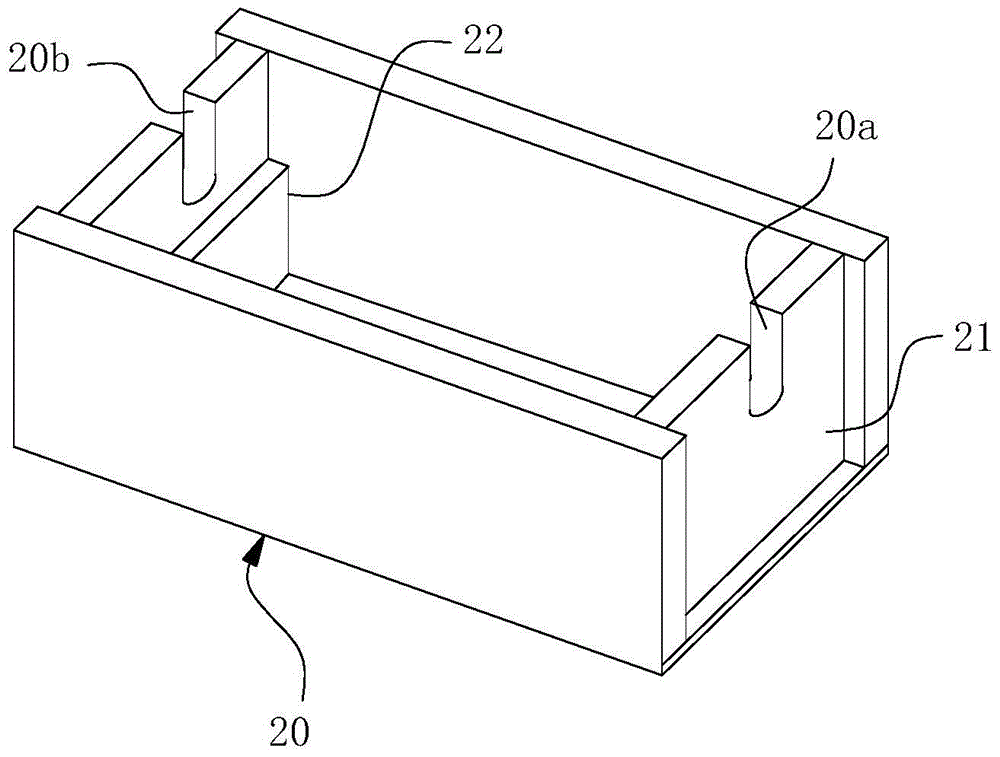

[0030] Concrete working structure of the present invention is as Figure 1-5 As shown, it includes a stepped cylindrical paint mold 10 arranged on the support at the enamelling machine b place, the large end of the paint mold 10 is located at the end where the wire inlet is located, and each paint mold 10 is multiple and along its diameter Set to parallel uniform distribution. According to the difference in the number of painting steps required by each paint layer, the number of painting molds 10 used in each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com