Screw thread automatic detecting equipment and method

An automatic detection and thread technology, applied in the direction of mechanical diameter measurement, etc., can solve the problems of difficult to realize automation and high efficiency of assembly line production, high labor intensity of workers, and low efficiency of methods, so as to reduce the risk of defective products, significant economic benefits, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structural features of the present invention will be described in detail below in conjunction with the accompanying drawings.

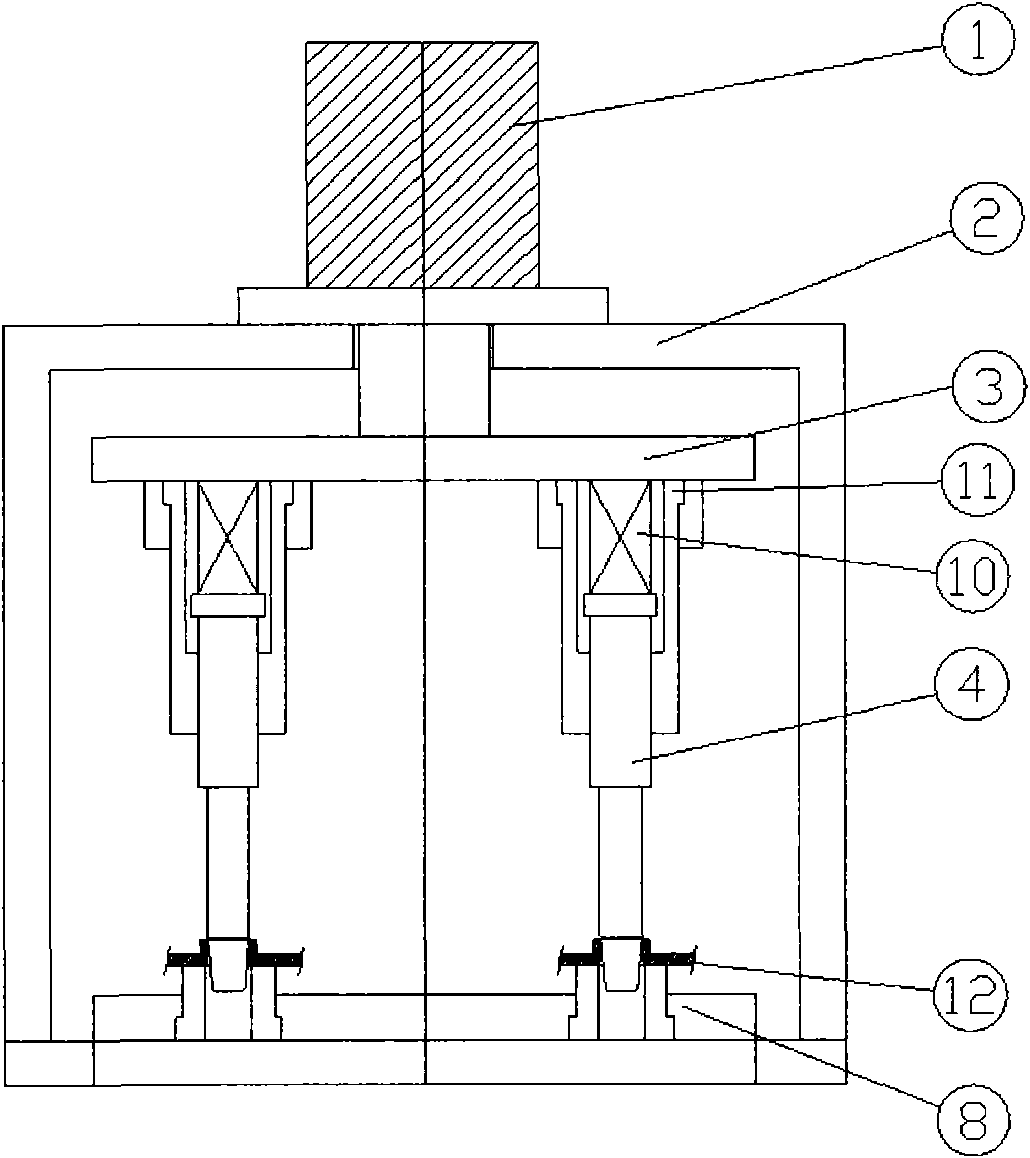

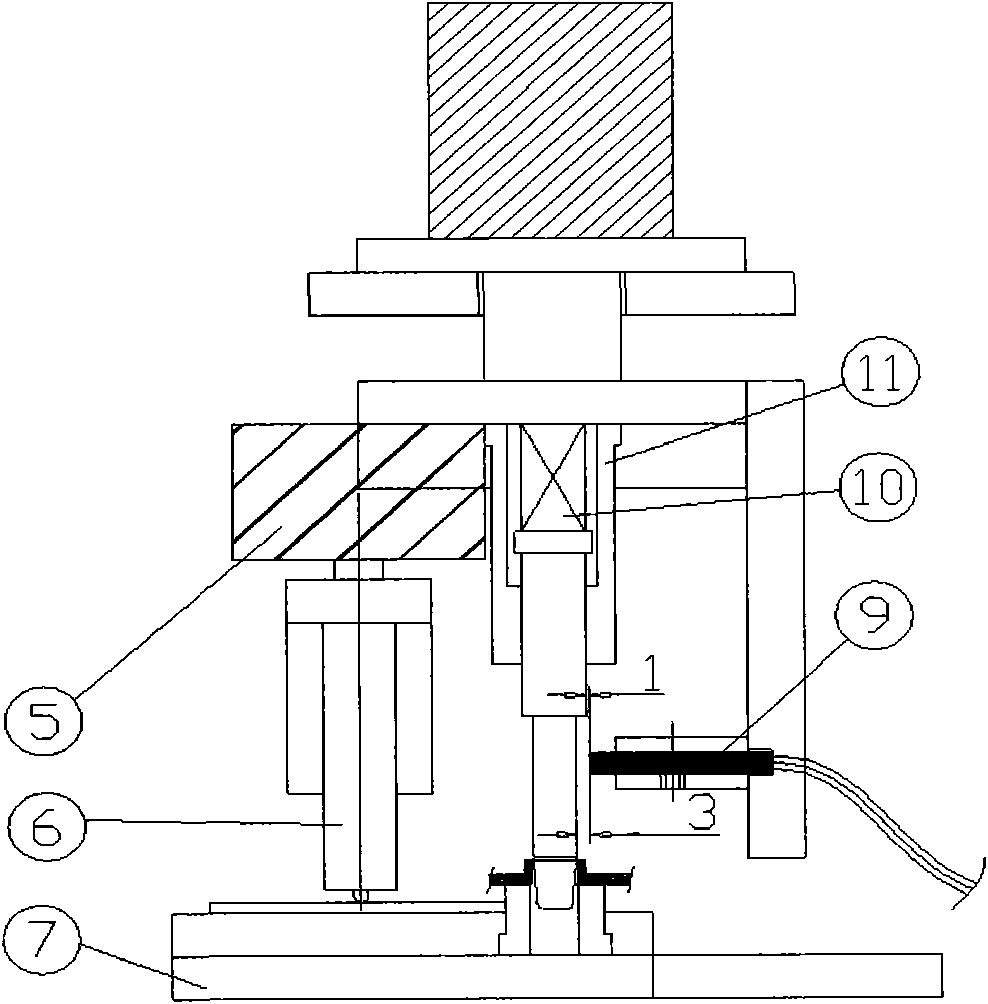

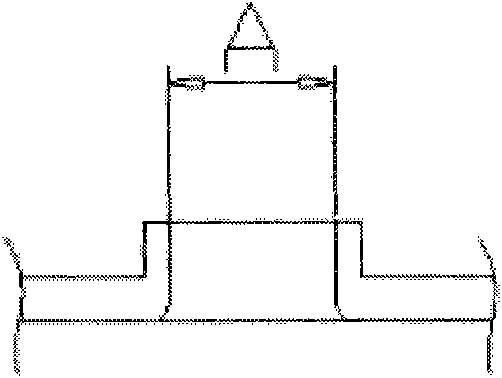

[0018] Such as figure 1 and figure 2 As shown, the thread automatic detection equipment is composed of the following parts: working cylinder 1, gantry fixed frame 2, cylinder slide 3, thread detection pin 4, thin cylinder 5, oily marker pen 6, base 7, product detection fixture 8, sensor 9. Detection pin buffer spring 10, detection pin fixed bushing 11, and control system and circuit system; wherein, the threaded detection pin 4 is a stepped shaft structure, and the thinner part at the front end is a threaded detection rod, which is in phase with the detection pin buffer spring 10 The fixed portion of the rear end of the connected thread detection pin 4 is relatively thick, and the sensor is triggered to detect whether the product is qualified or not by inserting the thread detection rod or being prevented from descending to produce differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com