Middle packaging machine

A technology of chartered planes and racks, which is applied in the field of medium chartered planes, can solve the problems of increased labor costs, labor intensity of workers, unreasonable combination of electrical control parts, poor adaptability of product specifications, etc., and achieve the effect of assembly line operation, compact structure, and fast sealing and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the technical solutions of the present invention, the embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

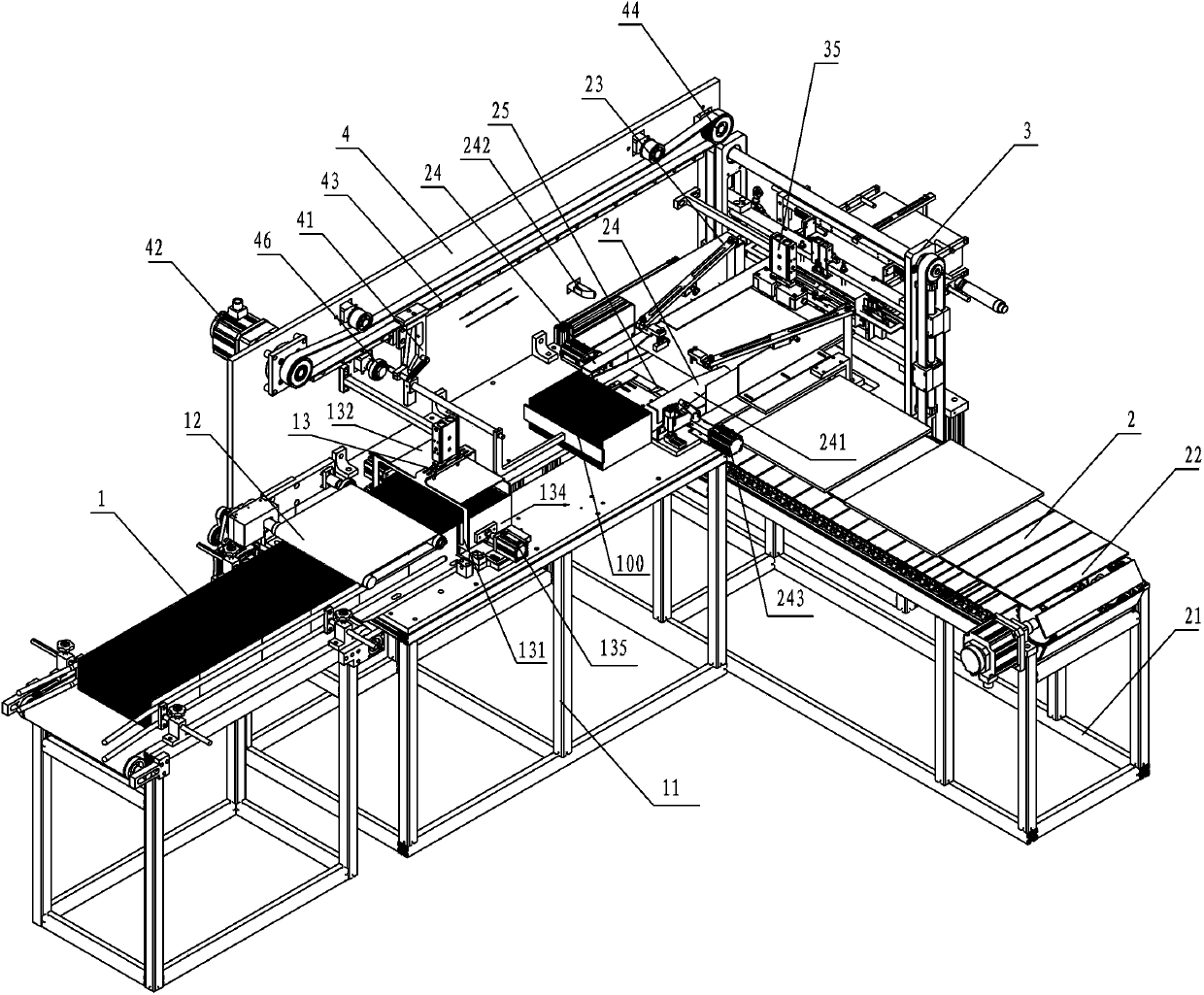

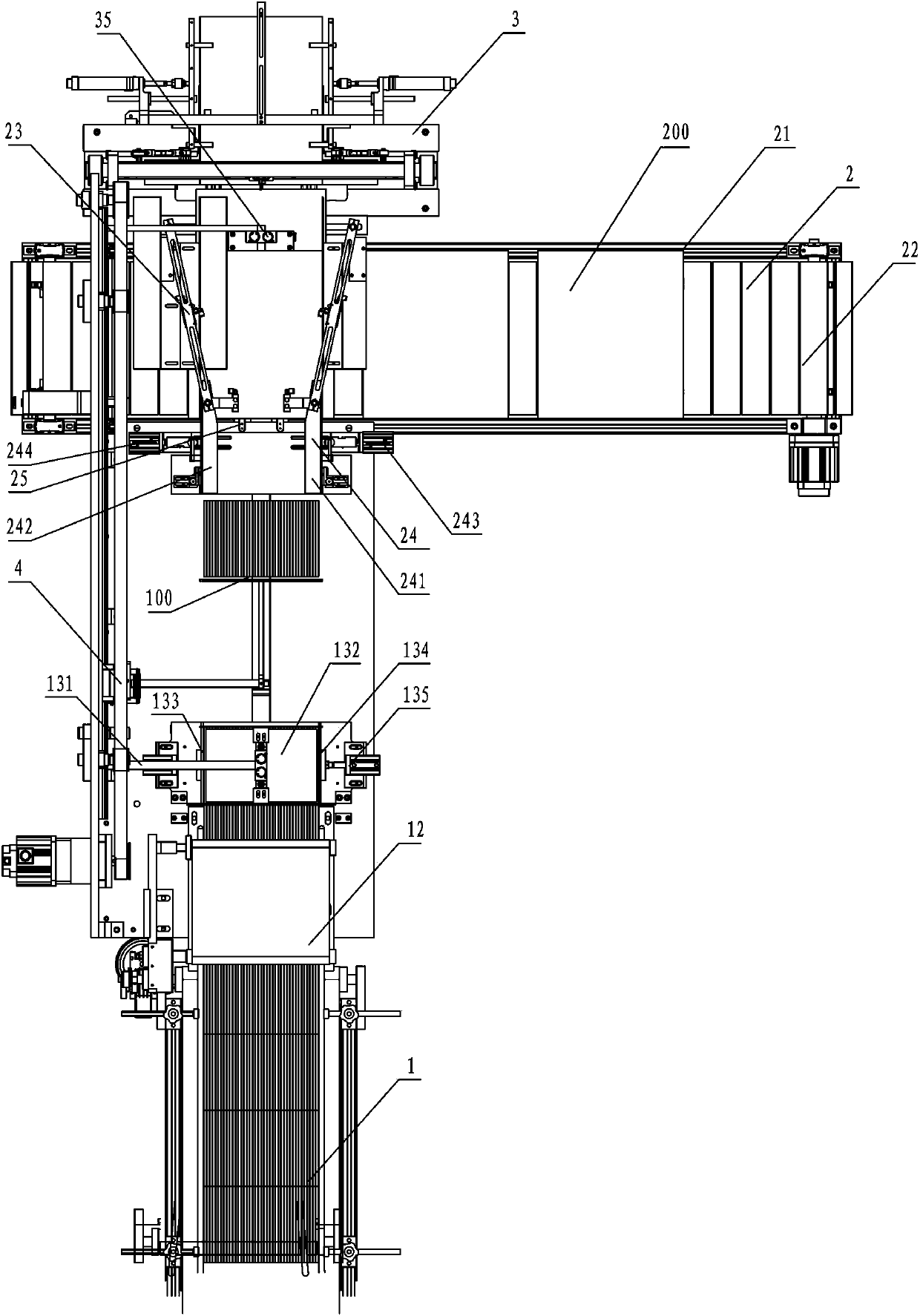

[0029] refer to figure 1 As shown, a middle bag machine includes a feeding line 1, a packaging bag conveying line 2 and a packaging bag sealing and cutting machine 3 connected in sequence, and also includes a push rod for pushing the product 100 from the feeding line 1 to the packaging bag sealing and cutting machine 3 Institution 4.

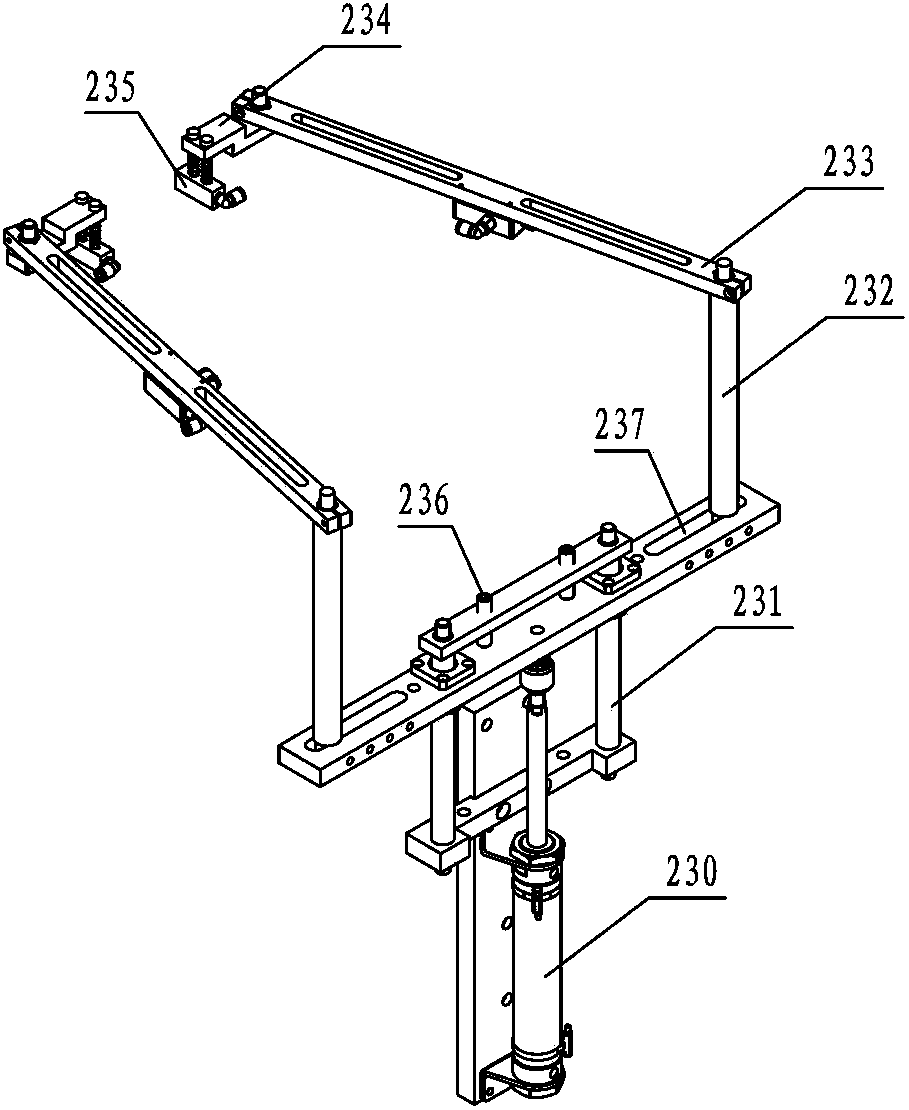

[0030] refer to figure 1 , figure 2 As shown, the feeding assembly line 1 includes a frame 11, a feeding device 12 and a compacting mechanism 13 arranged on the frame 11, and the compacting mechanism 13 includes a positioning frame 131, an upper pressing plate 132, a left pressing plate 133, and a right pressing plate 134 1. Press plate driving cylinder 135, positioning frame 131 can be lifted and arranged above feeding devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com