Laser precision micro machining device and method of light guide plate

A technology of microfabrication and light guide plate, applied in the direction of measuring device, laser welding equipment, metal processing equipment, etc., can solve the problems of different quality of laser light source, low processing efficiency, high defect rate of light plate scattering network, and reduce labor cost , improve efficiency, and achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The laser precision micromachining device and the processing method of the light guide plate of the present invention will be described in detail below in conjunction with the accompanying drawings.

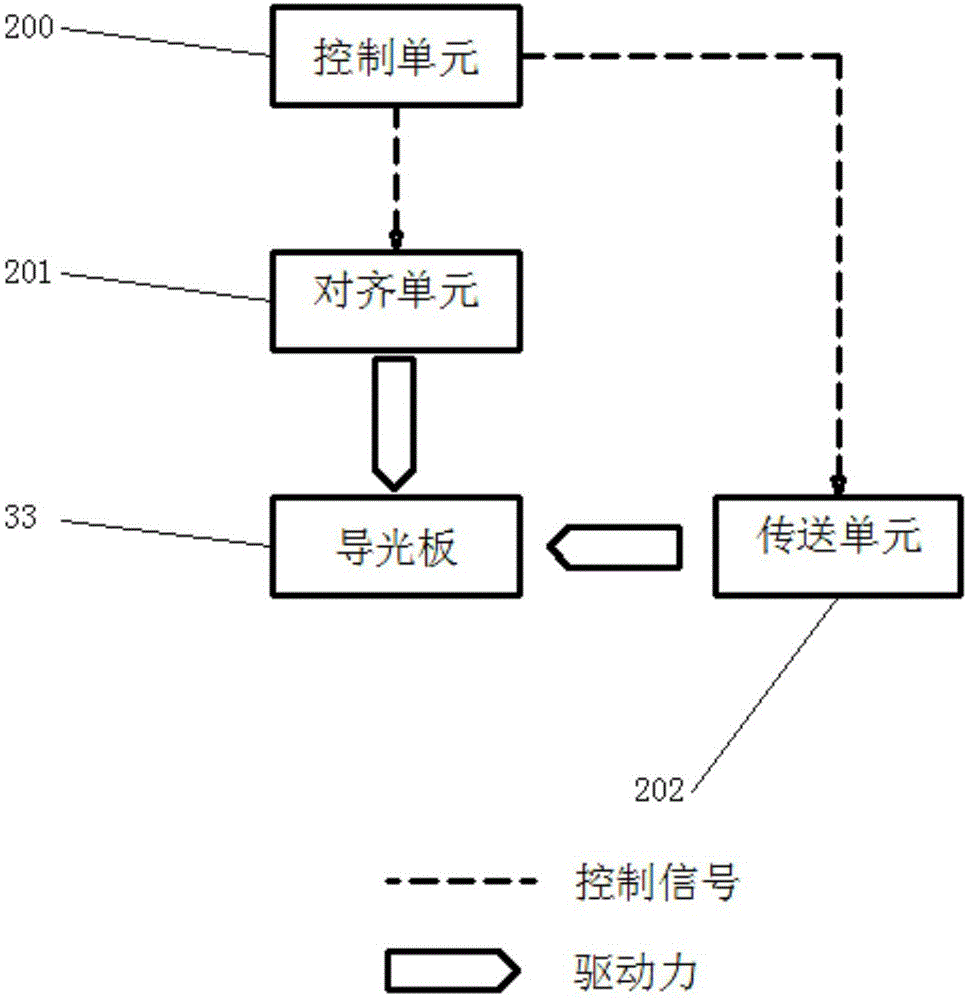

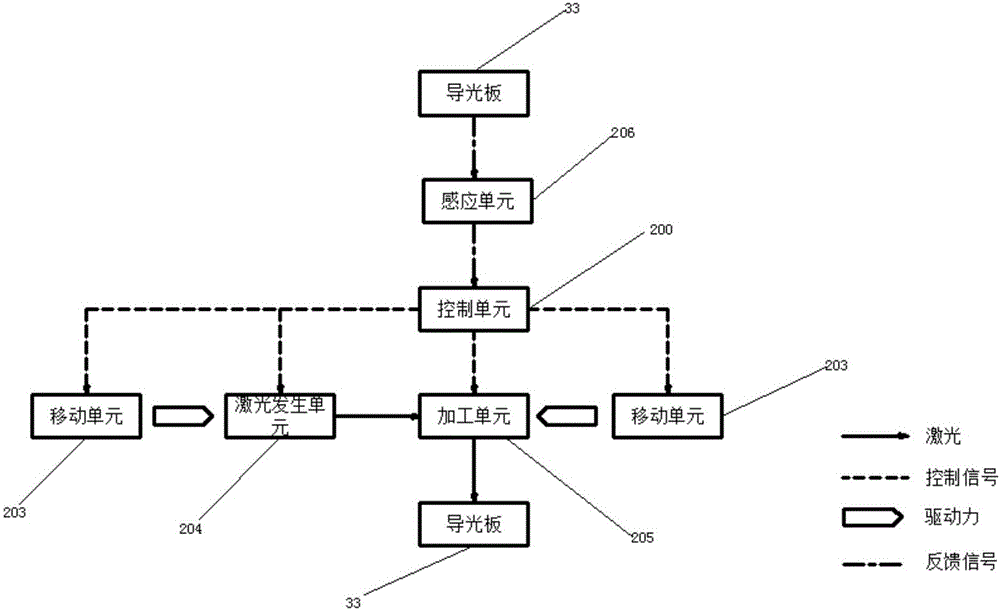

[0042] Such as figure 1 As shown, it is a relationship diagram between the transmission unit, the automatic alignment unit and the control unit of the light guide plate laser precision micromachining device of the present invention;

[0043] It includes: a transmission unit 202: a mechanism for transmitting the light guide plate for processing scattered dots; an automatic alignment unit 201: a mechanism for adjusting the position of the processed light guide plate; a control unit 200: used for controlling each unit;

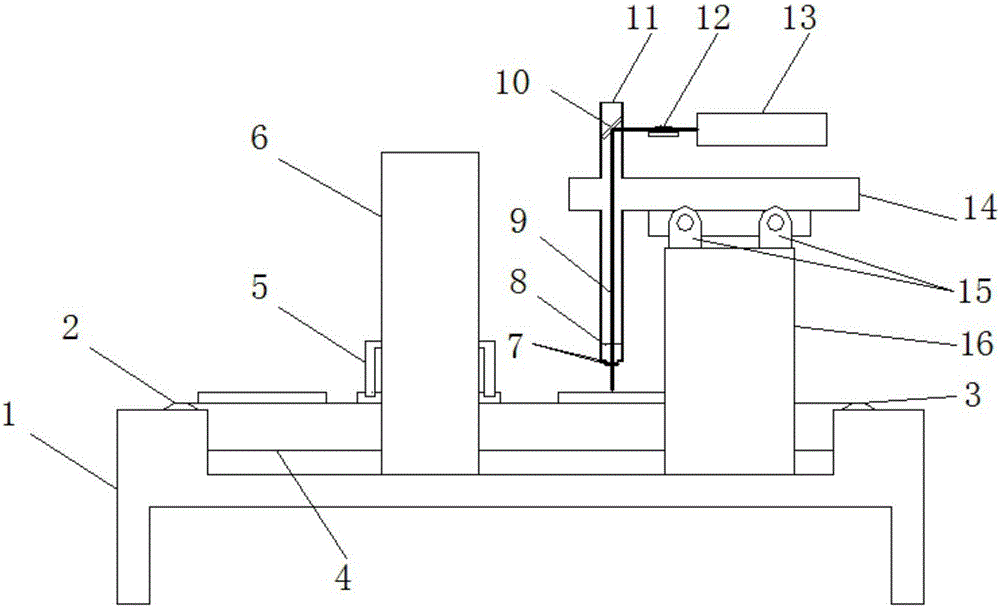

[0044] The sending unit 202 includes: image 3 , rollers 2, 3, and a conveyor belt 4, which are used to transport the light guide plate 34 for processing during the entire processing process.

[0045] The automatic alignment unit 201 includes: Figure 5 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com