Sample delivery system for chemiluminescence instrument

A chemiluminescent instrument and delivery system technology, applied in the direction of instruments, analytical materials, etc., can solve the problems of low automation and inability to realize dynamic sample loading, and achieve the effect of high automation and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and specific embodiments.

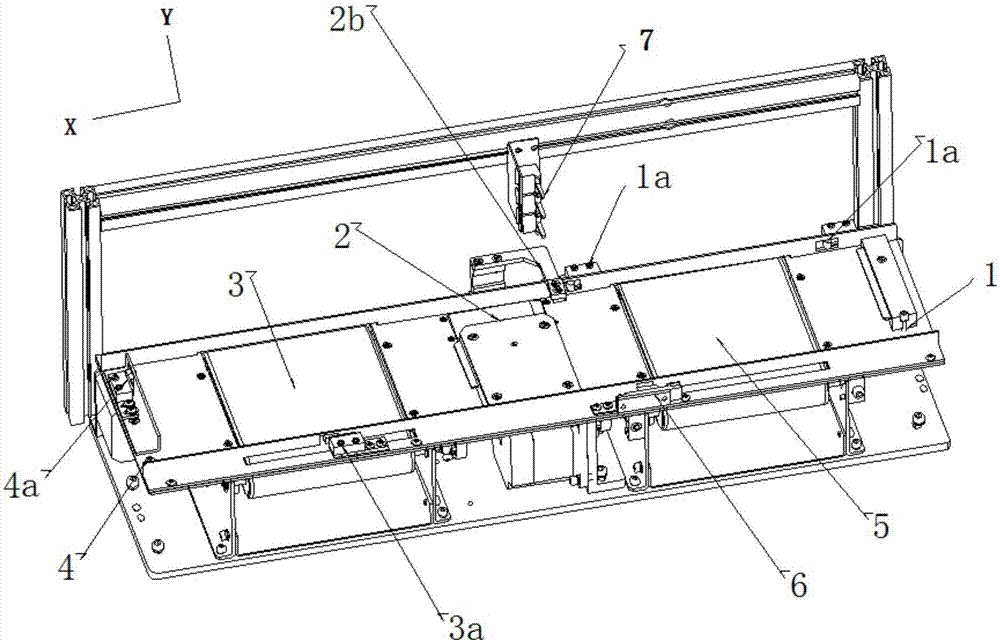

[0020] See figure 1 , A sample delivery system for a chemiluminescence instrument, the sample delivery system is independent as a module, with a horizontal delivery channel and a control system; the delivery channel includes a sample injection intercommunication structure 1 and a sample loading area in the X direction 5. Sample processing area 2, sample withdrawal area 3, sample withdrawal intercommunication structure 4; the sample loading area 5 has a sample loading conveyor belt mechanism that transports the test tube rack forward along Y, and the sample loading conveyor mechanism has a second micro The second micro switch automatically controls and starts the sample loading conveyor belt mechanism; the sample injection intercommunication structure 1 is provided with a pair of first micro switches 1a for detecting the test tube rack in place. The micro swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com