Supercritical fluid chromatographic separation method and device

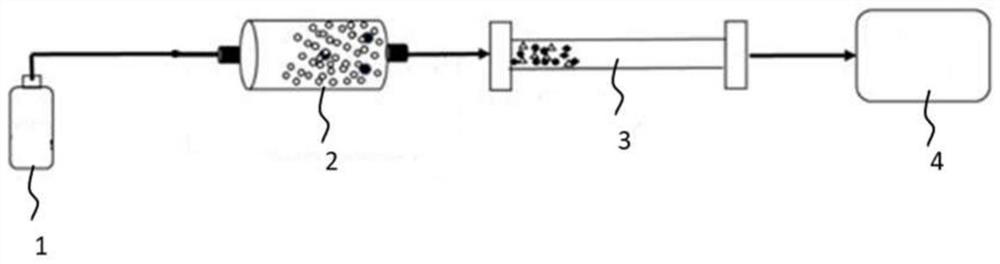

A supercritical fluid and chromatographic separation technology, which is applied in the field of supercritical fluid chromatographic separation methods and devices, can solve problems such as difficult elution, band broadening, and decrease in resolution, and achieve the effects of convenient operation, elimination of interference, and improvement of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

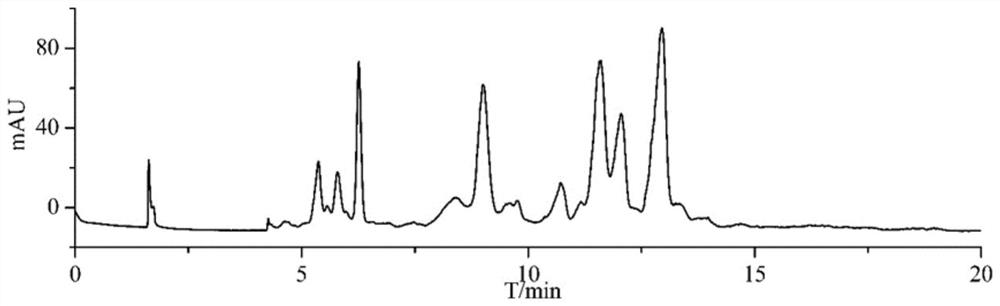

Embodiment 1

[0055] The materials and material specifications used in this embodiment are as follows:

[0056] Sample: the precipitate of Hedyotis diffusa after extraction with 95% ethanol and water sinking;

[0057] Chromatography packing: C18 (40μm, 100A);

[0058] Pre-separation device specification: 5mL;

[0059] Supercritical fluid preparative chromatographic column specification: 250×10mm i.d., 10μm.

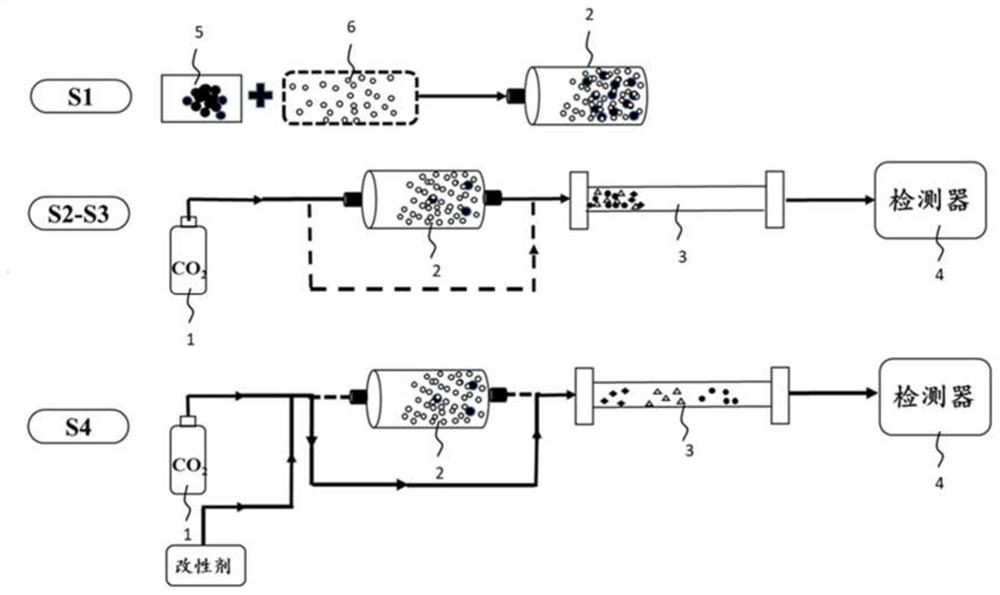

[0060] The supercritical fluid chromatographic separation method of the present embodiment comprises the steps:

[0061] S1: Preparation of sample and chromatographic packing mixture

[0062] Weigh the dried powder of Hedyotis diffusa (100 g), add 95% ethanol (800 mL) with 8 times the ratio of solid to liquid, and extract twice under reflux, each time for 1 hour. The two extracts were combined and concentrated to 20 mL under reduced pressure with a rotary evaporator to obtain a dark green extract. Slowly add 100 mL of water to the extract under stirring condition, and after standi...

Embodiment 2

[0068] The materials and material specifications used in this embodiment are as follows:

[0069] Sample: the precipitate of Hedyotis diffusa after extraction with 95% ethanol and water sinking;

[0070] Chromatography packing: C18 (40μm, 100A);

[0071] Pre-separation device specification: 5mL;

[0072] Supercritical fluid preparative chromatographic column specification: 250×20mm i.d., 10μm.

[0073] The supercritical fluid chromatographic separation method of the present embodiment comprises the steps:

[0074] S1: Preparation of sample and chromatographic packing mixture

[0075] The preparation method of the Hedyotis diffusa sample is the same as in Example 1.

[0076] Weigh 1.0 g sample of Hedyotis diffusa into a mortar, add a small amount of ethanol to dissolve the sample. Subsequently, 3.0 g of C18 (40 μm, 100A) chromatographic filler was added to the solution, and after grinding evenly, the solvent was evaporated to prepare a mixture of the sample and the chromat...

Embodiment 3

[0082] The materials and material specifications used in this embodiment are as follows:

[0083] Sample: the precipitate of Hedyotis diffusa after extraction with 95% ethanol and water sinking;

[0084] Chromatographic packing: C8 (40μm, 100A);

[0085] Pre-separation device specification: 25mL;

[0086] Supercritical fluid preparative chromatographic column specification: 250×30mm i.d., 10μm.

[0087] The supercritical fluid chromatographic separation method of the present embodiment comprises the steps:

[0088] S1: Preparation of sample and chromatographic packing mixture

[0089] The preparation method of the Hedyotis diffusa sample is the same as in Example 1.

[0090]Weigh 2.0 g of Hedyotis diffusa sample into a mortar, add a small amount of ethanol to dissolve the sample. Subsequently, 8.0 g of C8 (40 μm, 100A) chromatographic filler was added to the solution, and after grinding evenly, the solvent was evaporated to prepare a mixture of the sample and the chromato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com