Chromatography sampling device and method

A sampling device and sampling technology, applied in the field of chromatographic analysis, can solve the problems of severe solvent peak broadening, large liner volume, high operator requirements, etc., so as to reduce the use cost and maintenance cost, the heating device is simple, and the sensitivity is improved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

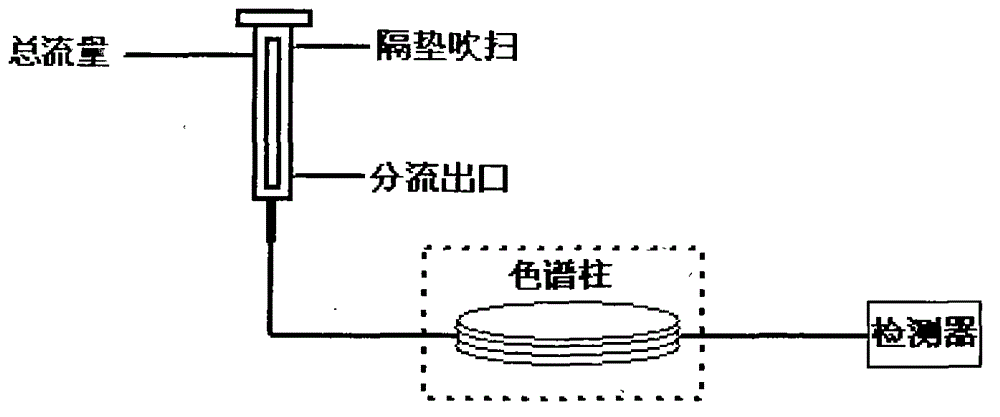

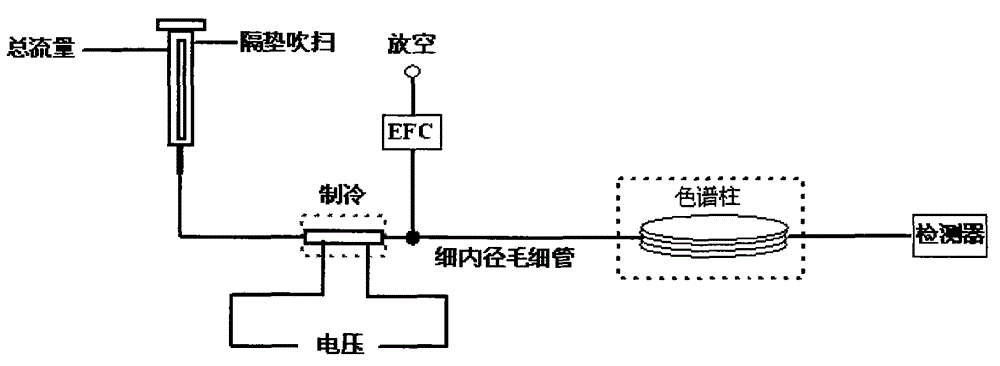

[0041] figure 2 Schematically provides the basic structure diagram of the chromatographic sampling device of the embodiment of the present invention, as figure 2 As shown, the sampling device includes:

[0042] Adsorption-thermal desorption module, the adsorption-thermal desorption module is the prior art in this field, and will not be repeated here.

[0043] A gas channel, the gas channel is arranged downstream of the adsorption-thermal desorption module; preferably, the gas channel is made of stainless steel tubes, which can withstand rapid cooling and rapid heating.

[0044] packing, the packing is arranged in the gas channel, and is used to absorb the gas discharged from the adsorption-thermal desorption module when the temperature control module is cooled and the thermal desorption gas when the temperature control module is heated;

[0045] A temperature control module, the temperature control module is arranged on the gas channel, and is used for cooling and heating ...

Embodiment 2

[0053] According to the application example of the sampling device and method in Example 1 of the present invention in gas chromatography, in this application example, splitless sampling is specifically adopted.

[0054] In this application example, the temperature control module adopts a thermoelectric cooler, the gas channel adopts a stainless steel tube, an EFC is arranged on the exhaust channel, and a stainless steel tube with a thin inner diameter is arranged on the analysis channel. The sample injection method is as follows:

[0055] (B1), sample injection

[0056] After the sample enters the injection port through the injection needle, the solvent and the sample are simultaneously vaporized and injected in the liner at high temperature, and are brought into the thermoelectric cooler through the total flow.

[0057] (A1) Sample focusing

[0058]Before sample injection, the semiconductor chip in the thermoelectric cooler has started to work, and the sample can only be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com