Manufacturing equipment and manufacturing method for flexible metal tube

A production method and technology for metal pipes, which are applied in metal processing equipment, shearing machine equipment, pipe cutting devices, etc., can solve the problems of inability to realize automatic flow operation, non-uniform cutting length of metal pipes, and long machine pause time. Avoid the empty running of the equipment without material, realize the effect of assembly line operation and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

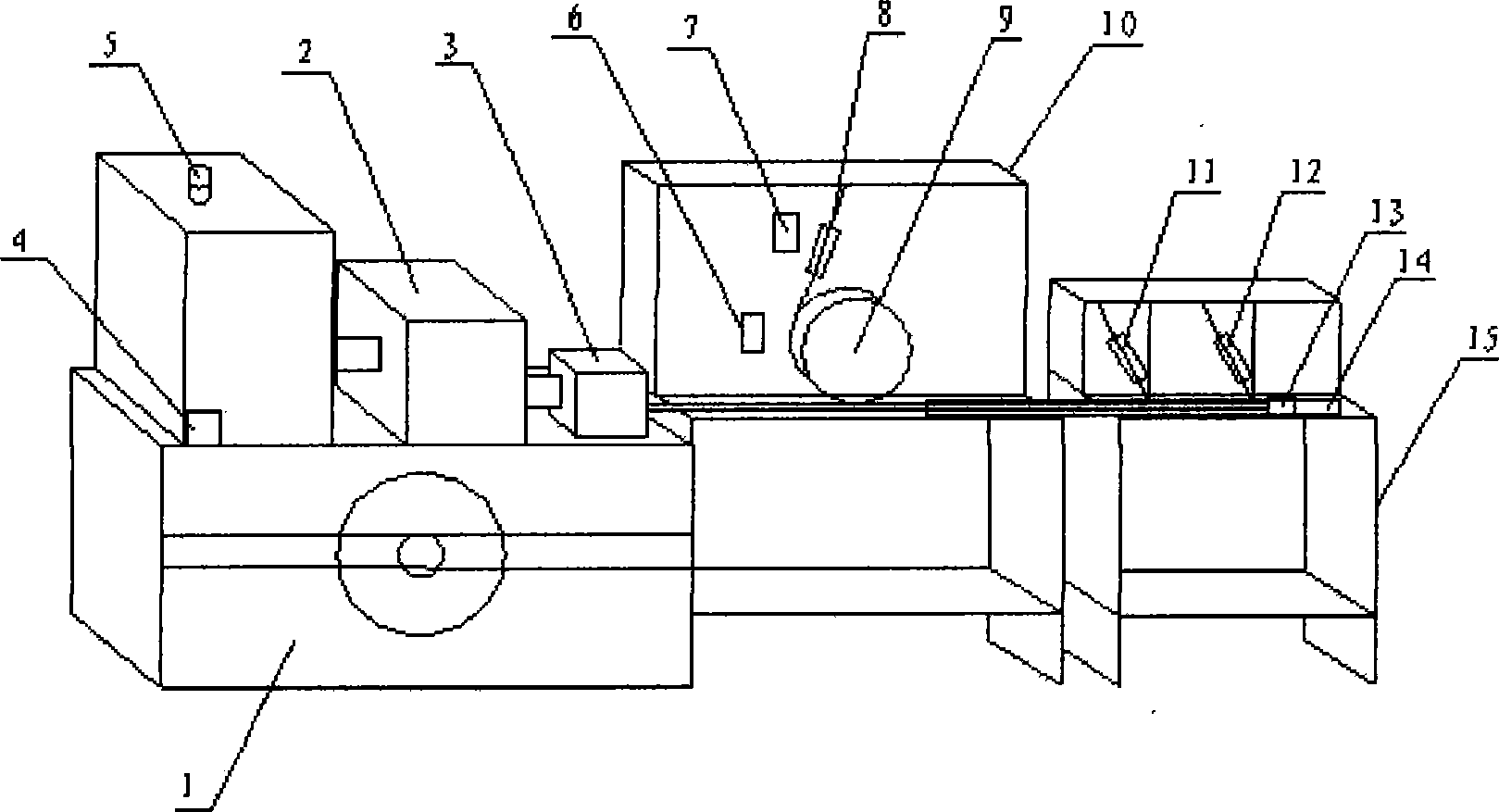

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] see figure 1 , is a structural diagram of a production equipment for a flexible metal tube proposed by the present invention.

[0024] Such as figure 1 As shown, a kind of production equipment of flexible metal pipe comprises pipe making machine main body, cutting machine main body, suspended gantry 15 and PLC control cabinet 10, and described pipe making machine main body is connected with described cutting machine main body, and described cutting machine main body The main body of the machine is connected with the suspended gantry 15; the main body of the pipe making machine includes a pipe making machine 3, an alarm device for shutting down without material, a raw material connection device 2 and a tray support 1, and a stop without material is set on the tray support 1. Alarm device, the raw material connection device 2 is connected to the input end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com