Shell-and-tube dry type evaporator

A dry evaporator, shell-and-tube technology, applied in evaporator/condenser, heat exchanger shell, heat exchange equipment, etc., can solve the problem of low working efficiency of shell-and-tube heat exchanger, etc. The effect of popularization and use, low manufacturing cost and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

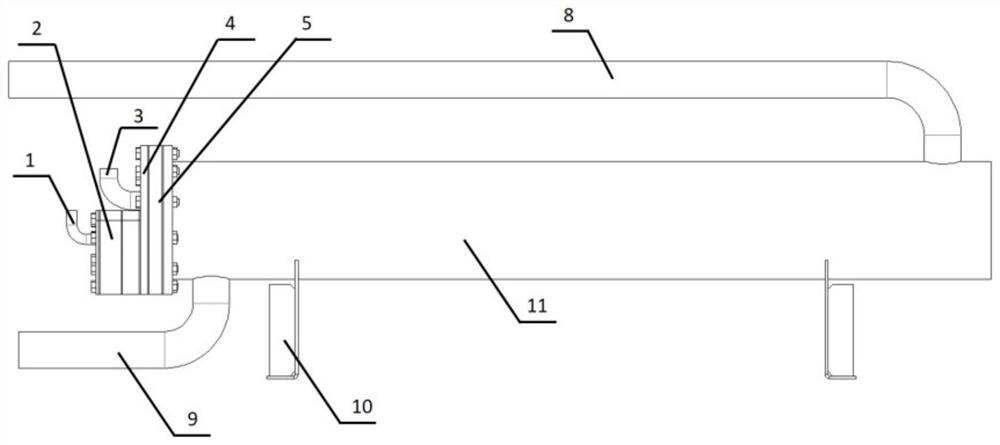

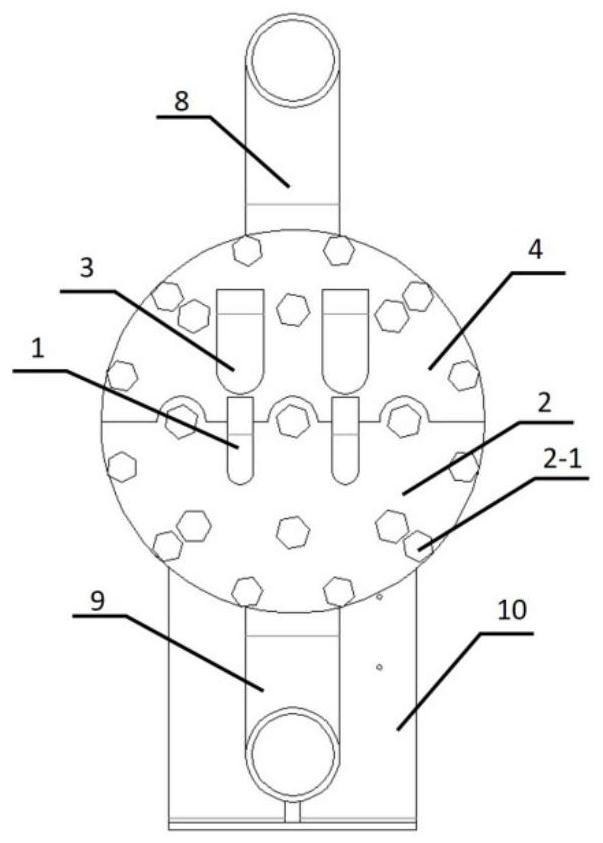

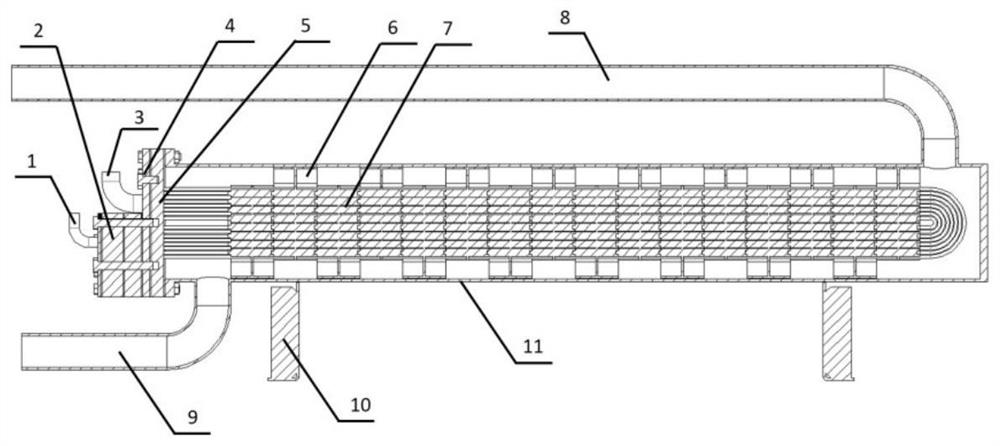

[0028] refer to Figure 1-Figure 6 , a shell-and-tube dry evaporator of the present invention includes a distributor 2, a refrigerant outlet pipe 3, an end cover 4, an arcuate baffle 6, a heat exchange tube 7, an outlet pipe 8, an inlet pipe 9, a bracket 10 and a cylinder body 11 etc.

[0029] The present invention is a dual-system shell-and-tube heat exchanger, which has two sets of independent inlets and outlets for refrigerant working fluid, and shares the water side for heat exchange.

[0030] One end of the cylinder body 11 is closed, and the other end is open. The cylinder body 11 is provided with heat exchange tubes 7 and arcuate baffles 6 , and the heat exchange tubes 7 are arranged in a square arrangement. The heat exchange tubes 7 pass through the arcuate baffles 6 , and a plurality of arcuate baffles 6 are arranged in a staggered manner to enhance heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com