Processing, shaping and modulation method of hollow retroreflector

A modulation method and retroreflector technology, applied in the field of optical instruments, can solve problems such as cumbersome process, high processing cost, and impossibility, and achieve the effect of increasing the optical opening, increasing product performance, and increasing passing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

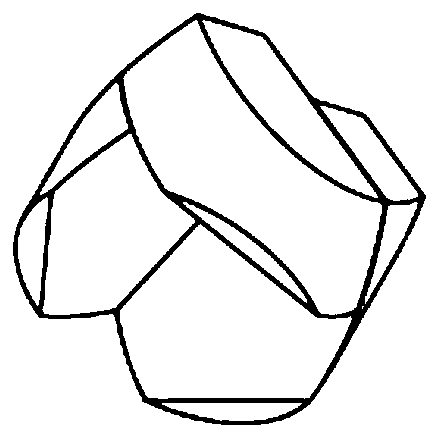

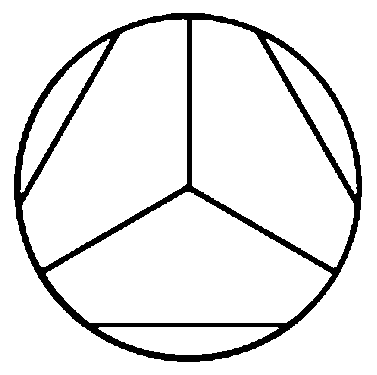

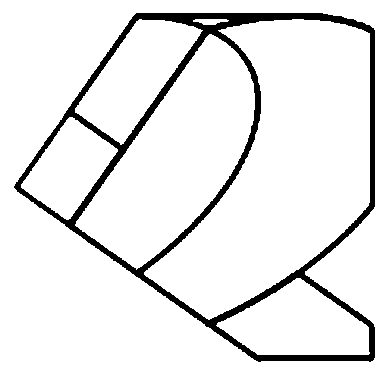

[0038] A method for processing, shaping and modulating a hollow retroreflector, comprising the following steps:

[0039](1) One side of the three square substrates used to assemble the hollow retroreflector is polished respectively, and the polished surfaces of the three square substrates are respectively connected with the three polished sides of the solid pyramid through the glue softened by heat Gluing, and the same glue is used to glue the three square substrates alternately. The bottom of the solid pyramid is a polished standard plane circle, and the three polished sides are rotationally symmetrical. The axis of symmetry is the polished standard plane at the bottom of the solid pyramid. The central axis of the circle; after polishing, it is beneficial to eliminate the lamination gap between the solid pyramid and the square substrate, and ensure the consistency of each square substrate during the cutting process. reflectivity.

[0040] (2) Taking the polished standard pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com