Casing gap blocking device and blocking method

A plugging device and casing technology, which is applied in the direction of pipes, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problem of low mortar/concrete bonding strength, small point contact area of flat chisels, and poor sealing of casing gaps and other problems, to achieve the effect of fast hardening operation time, avoiding processing difficulty and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The core of the invention is to provide a casing gap sealing device to improve the sealing performance of the casing gap. Another core of the present invention is to provide a casing gap sealing method.

[0035] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

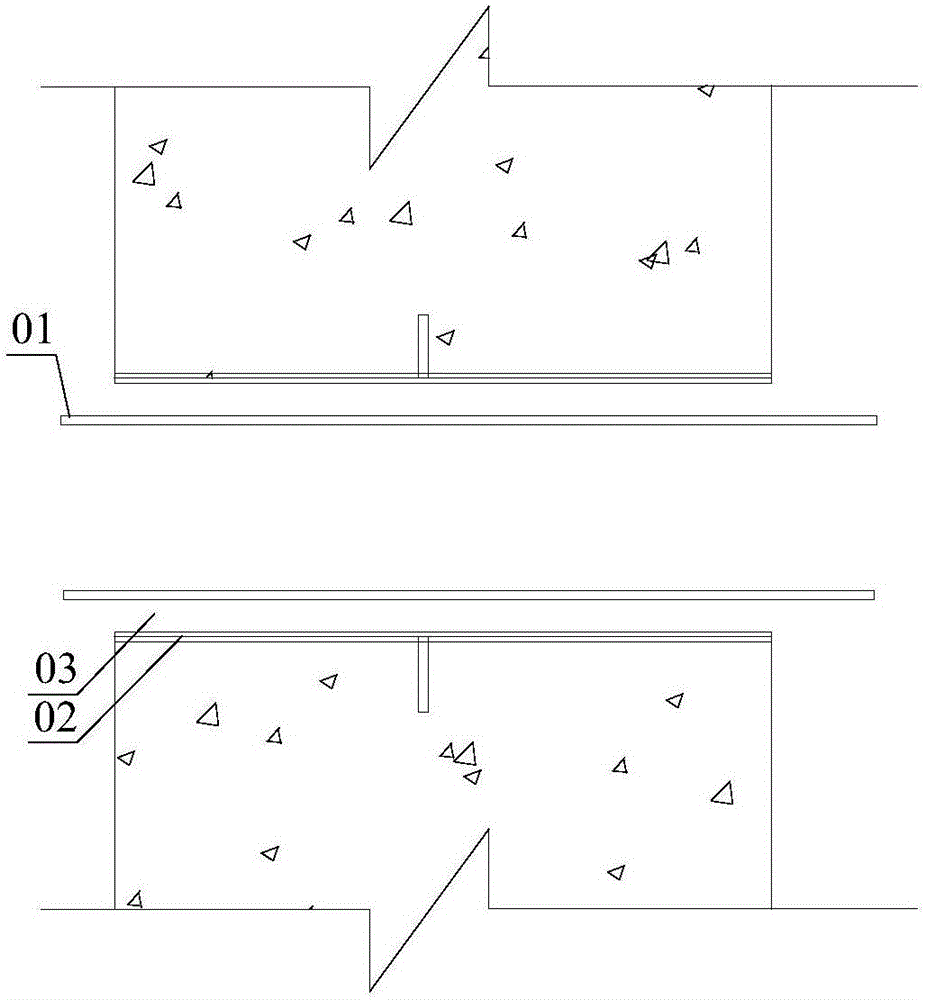

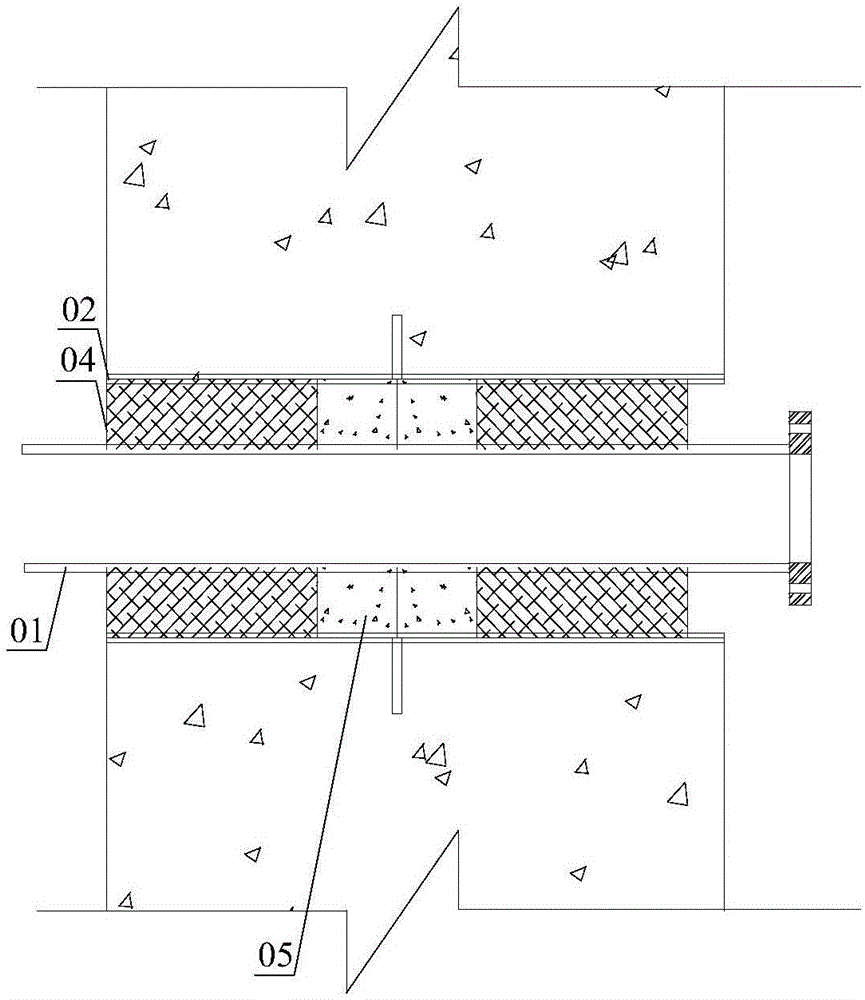

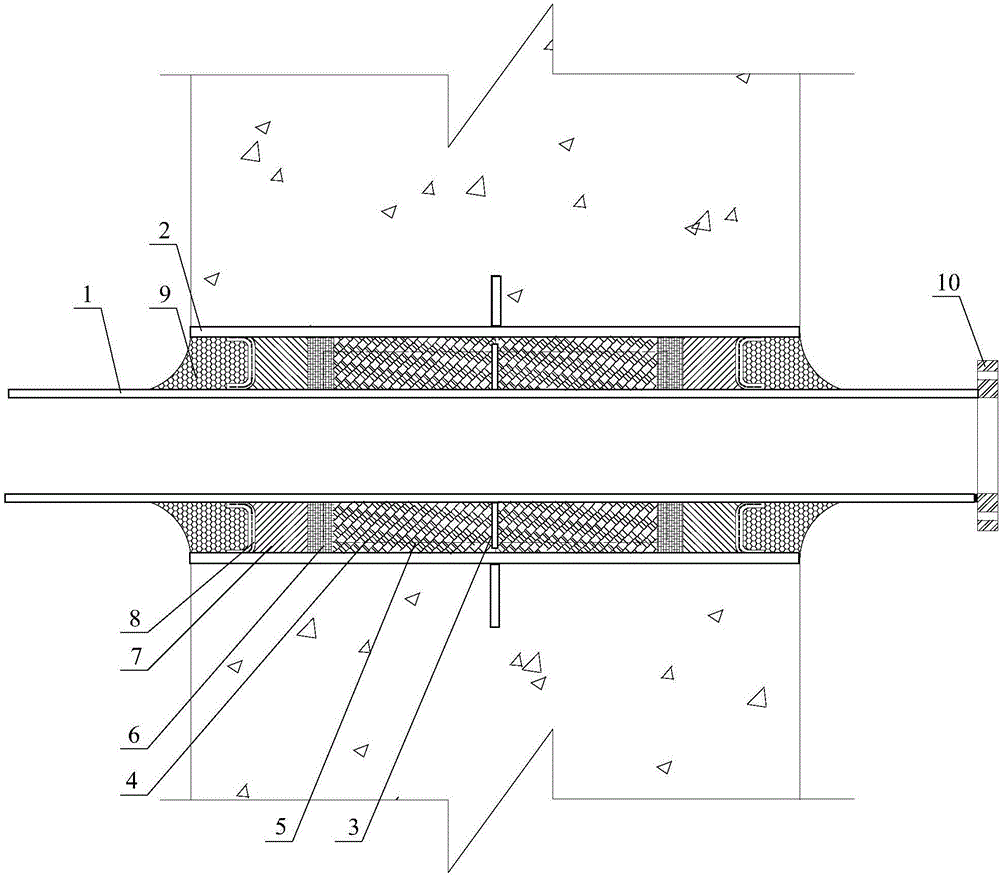

[0036] Please refer to Figure 3 to Figure 6 , in a specific embodiment, the casing gap sealing device provided by the specific embodiment of the present invention includes a pipe 1, a reinforcing plate 4, a backing ring 3 and a casing 2 sleeved outside the pipe 1, the backing ring 3 Sleeved on the outer wall of the pipeline 1, the side of the reinforcement plate 4 is fixedly connected to the outer wall of the pipeline 1, and the length direction of the reinforcement plate 4 extends along the axial direction of the pipeli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com