Numerical control gas cutting base supporting center

A cutting-edge, gas-cutting technology, applied in the field of CNC gas-cutting base supporting top, can solve the problems of ineffective supporting steel plate and deformation of the bottom plate, so as to save processing costs, increase service life, and avoid processing difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

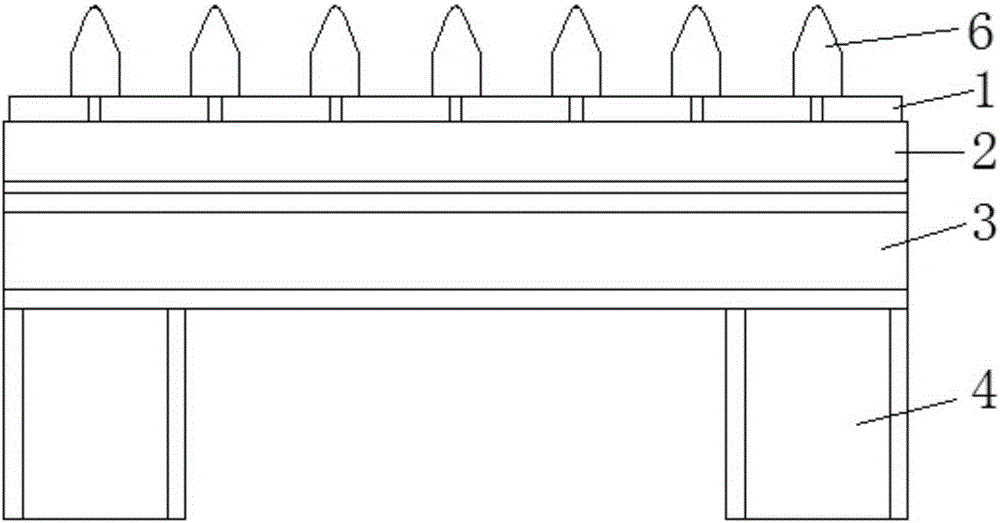

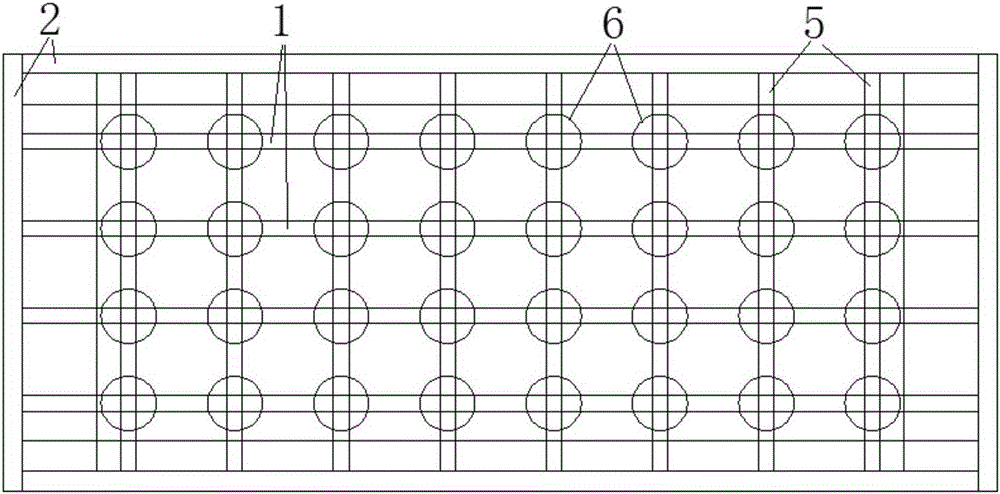

[0017] refer to figure 1 , figure 2 , the structure of the present invention is, comprises the longitudinal steel plate 1 and the transverse steel plate 5 that are well-shaped suit, all clamps a top 6 at each longitudinal steel plate 1 and each transverse steel plate 5 cross joints, in all longitudinal steel plates 1 and A circle of angle steel 2 is installed on the periphery of the transverse steel plate 5 (as the base peripheral surface baffle plate),

[0018] The lower surfaces of all the longitudinal steel plates 1 and the transverse steel plates 5 are jointly fixed with two sets of longitudinal H-shaped steels 3, and the two sets of longitudinal H-shaped steels 3 are used as base plane supports. On the shaped steel 4, two sets of horizontal H-shaped steel 4 are used as base support legs.

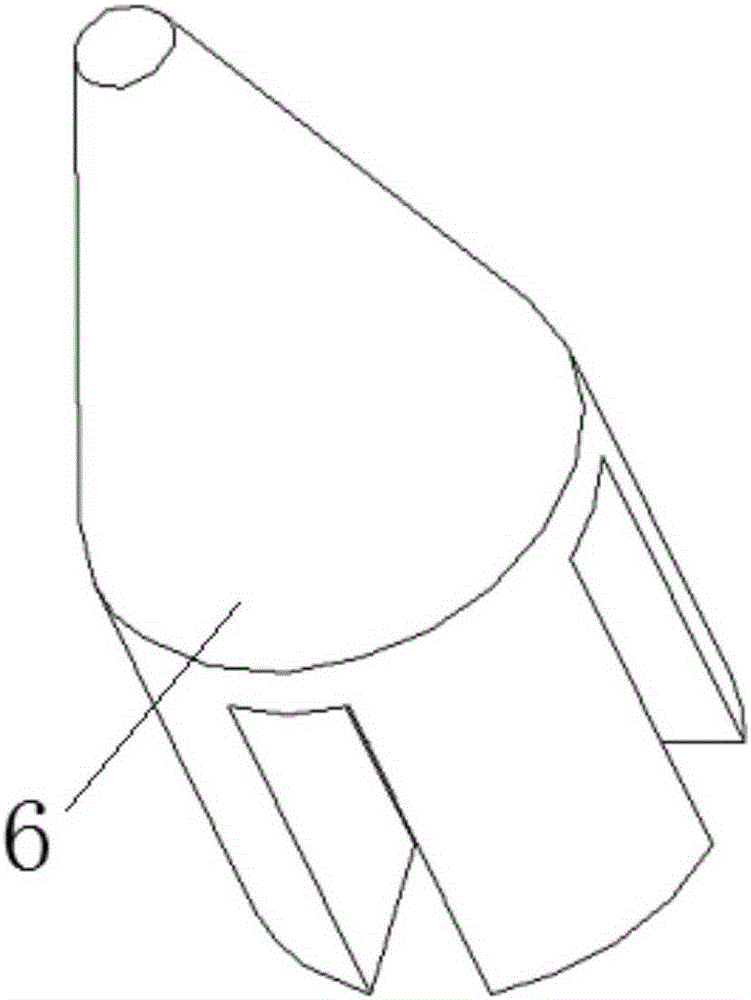

[0019] refer to image 3 , the top 6 adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com