Fat-based waste gas odor absorption agent, fat-based waste gas odor absorption plate, fat-based waste gas odor absorption plate preparation method, dry-method odor removing process, and dry-method odor removing equipment

An absorption plate and absorbent technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of easy saturation, limited adsorption efficiency of activated carbon, strong oxidative worker injury, etc., and achieve easy installation and maintenance. The effect of solving the processing difficulty and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] S1, take by weighing 28g sodium persulfate, 4.5g ferrous sulfate is added in 67.5g water, stir, sodium persulfate and ferrous sulfate are all dissolved, obtain mixed solution;

[0039] S2, take the foamed ceramic alumina base plate and soak it in the mixed solution of S1 for 15 minutes, remove it, and air-dry it for 250 minutes, so that sodium persulfate and ferrous sulfate are loaded on the base plate, and the load on the base plate The sodium persulfate on the surface is 0.6g, and the ferrous sulfate is 0.006g.

Embodiment 2

[0041] S1, take by weighing 30g sodium persulfate, 5g ferrous sulfate is added in 65g water, stir, sodium persulfate and ferrous sulfate are all dissolved, obtain mixed solution;

[0042] S2, take the foamed ceramic alumina base plate and soak it in the mixed solution of S1 for 20 minutes, remove it, and air-dry it for 225 minutes, so that sodium persulfate and ferrous sulfate are loaded on the base plate, and the load on the base plate The sodium persulfate on the surface is 0.9g, and the ferrous sulfate is 0.006g.

Embodiment 3

[0044] S1, take by weighing 32g sodium persulfate, 5.5g ferrous sulfate is added in 62.5g water, stir, sodium persulfate and ferrous sulfate are all dissolved, obtain mixed solution;

[0045] S2, take the foamed ceramic alumina base plate and soak it in the mixed solution of S1 for 25 minutes, remove it, and air-dry it for 200 minutes, so that sodium persulfate and ferrous sulfate are loaded on the base plate, and the load on the base plate The sodium persulfate above is 1g, and the ferrous sulfate is 0.0044g.

[0046] The quality of the sodium persulfate and ferrous sulfate loaded on the base plate in the above-mentioned embodiments 1-3 is obtained by measuring the concentration difference between sodium persulfate and ferrous sulfate in the solution before and after loading.

[0047] The substrate plates loaded with sodium persulfate and ferrous sulfate in Examples 1, 2, and 3 were respectively used in dry deodorization equipment.

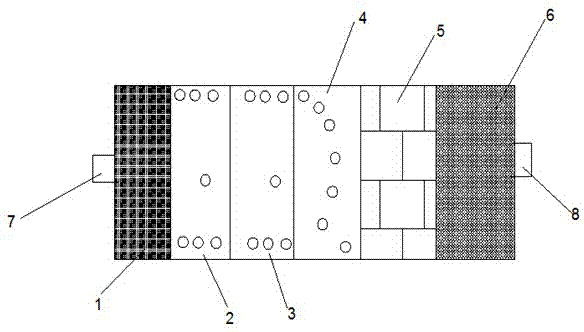

[0048] Such as figure 1 , a dry deodoriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com