High pressure angle throttle valve

A throttle valve and angle-type technology, which is applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of unstable flow control, inability to cut off the medium, and hidden dangers of well control safety, so as to avoid machining accuracy and installation The difficulty is too high, the effect of avoiding the accelerated erosion of the sealing ring line and reducing the requirements for grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

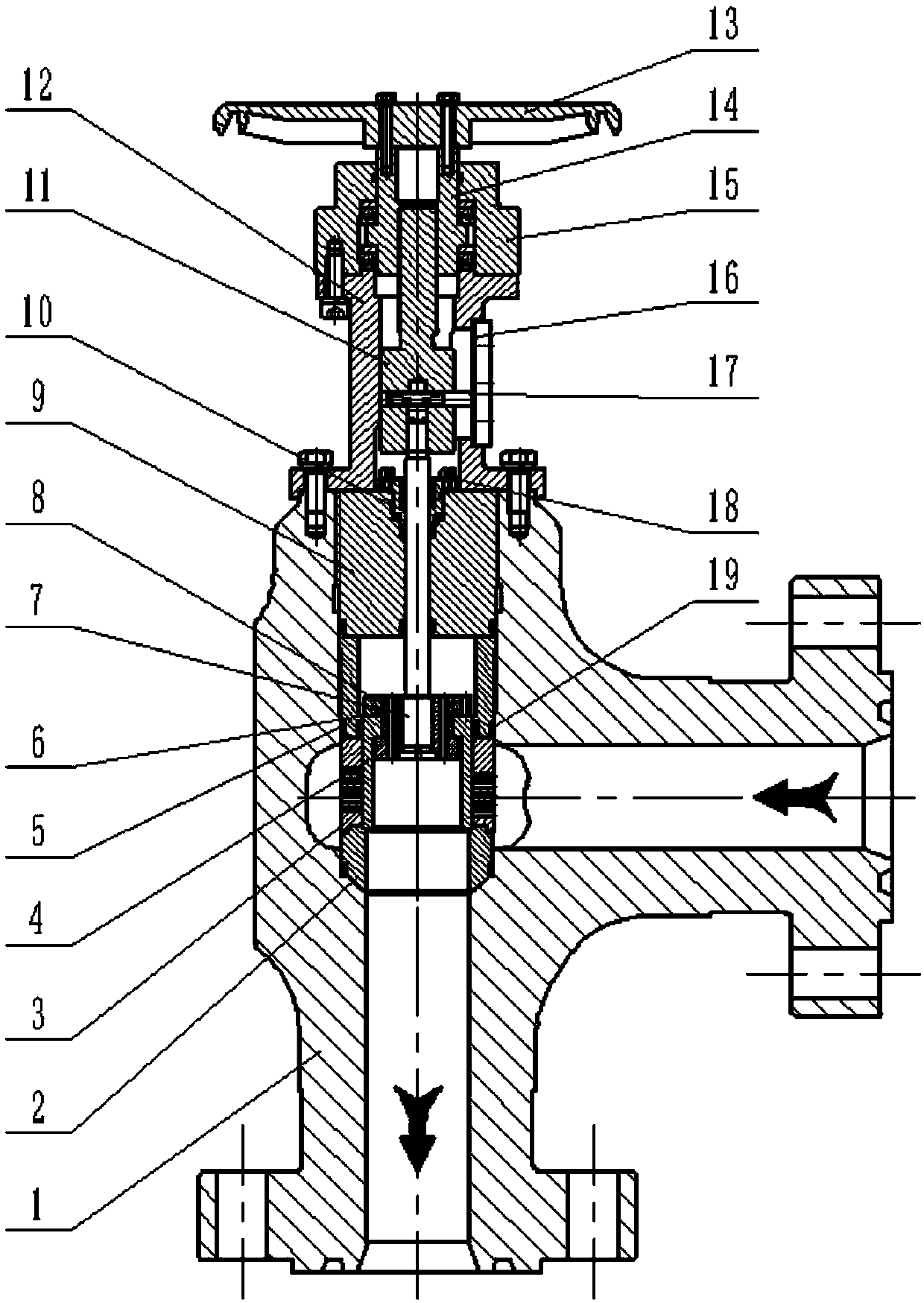

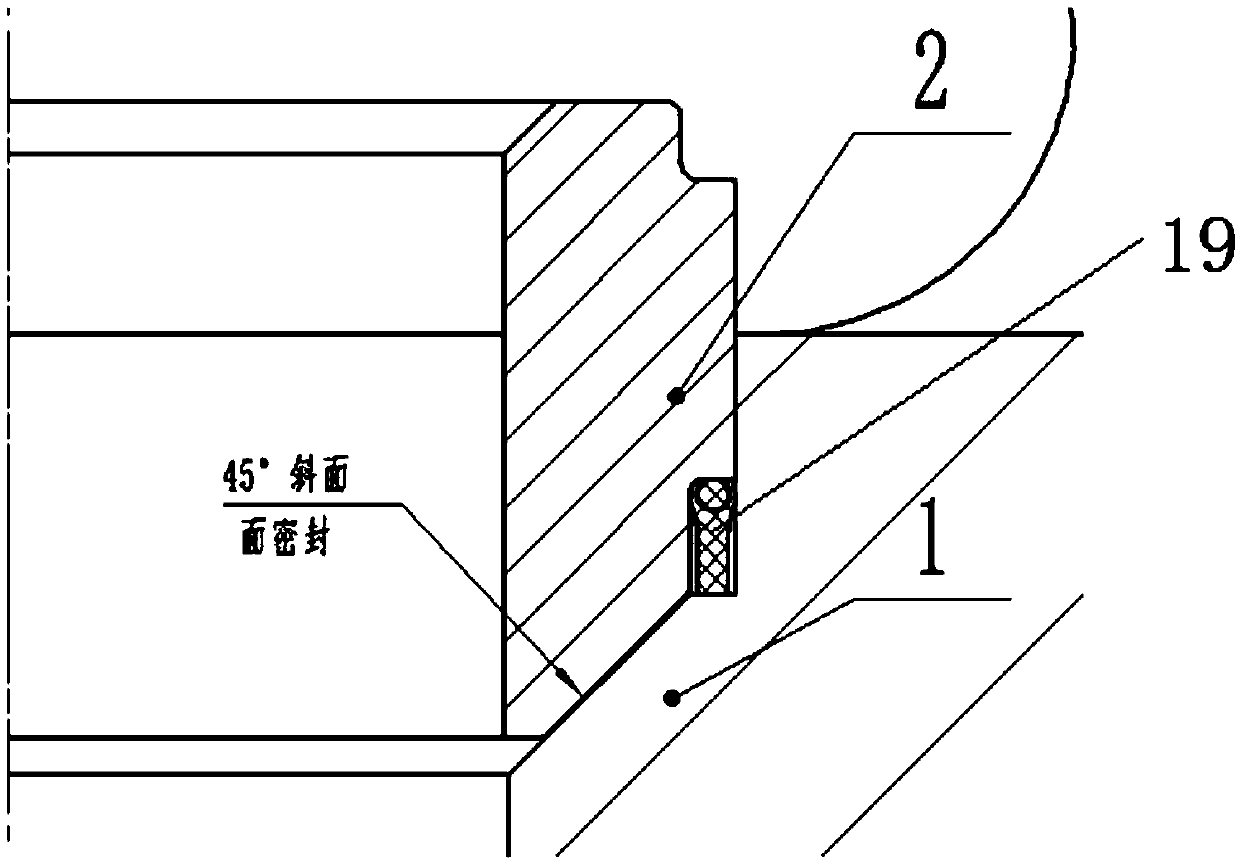

[0041] Such as figure 1 As shown, the high-pressure angle throttle valve disclosed by the present invention includes a valve stem 7, a valve core assembly, a valve seat 2, a sleeve 3, a coupling sleeve 11, a bracket 12, a hand wheel 13, a coupling sleeve nut 14, a shaft Sleeve 5, gland 9 and angle-shaped valve body 1, valve seat 2, sleeve 3, and shaft sleeve 5 are installed in valve body 1 in turn from bottom to top and pressed by gland 9. Gland 9 and valve body 1 screw connection.

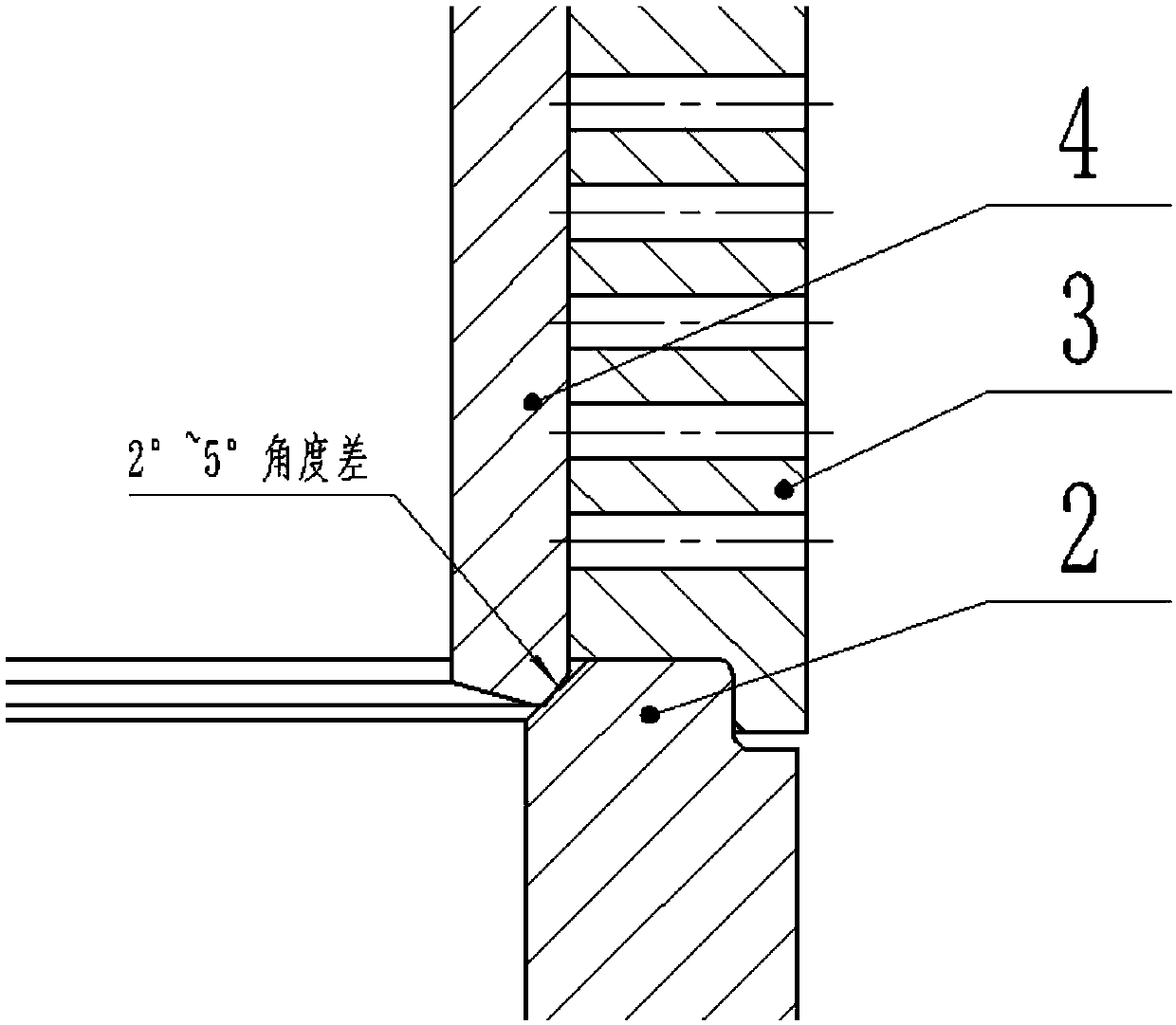

[0042] Such as figure 1 , 2 As shown, the sleeve 3 is provided with at least two longitudinal orifices in the circumferential direction, and at least some of the longitudinal orifices are staggered in the longitudinal direction; the lower end of the valve stem 7 extends into the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com