Concentration recovery system and method for active ingredients of machining cleaning solution

A technology for machining cleaning liquid and active ingredients, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., to reduce the cost of sewage treatment, increase the efficiency of waste liquid treatment, and improve recovery Efficiency and Effects on Recycled Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

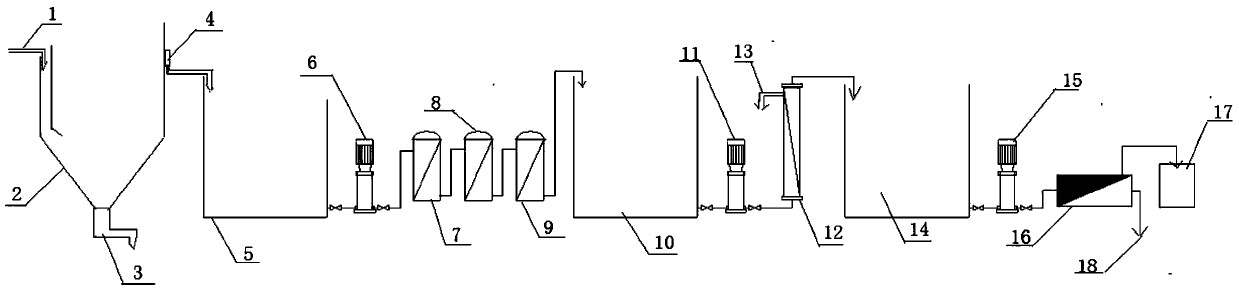

[0035] Such as figure 1 As shown, a system for concentrating and recovering the effective components of the machining cleaning liquid is composed of a waste liquid inlet 1, a sedimentation tank 2 connected to the end of the waste liquid inlet 1, and a sedimentation outlet 3 arranged on the bottom of the sedimentation tank 2, which is installed in the sedimentation tank 2. The suction pump 4 on the upper side of the tank 2, the supernatant liquid tank 5 connected to the liquid suction pump 4, the booster pump a6 arranged on the lower side of the supernatant liquid tank 5, and the booster pump a6 on the upper side of the middle Connected coarse filter 7, primary fine filter 8 connected to the lower side of the coarse filter 7, secondary fine filter 9 connected to the lower side of the primary fine filter 8, filtrate connected to the secondary fine filter 9 Tank 10, the booster pump b11 connected to the lower side of the filtrate tank 10, the ultrafiltration system 12 connected to ...

Embodiment 2

[0045] On the basis of Embodiment 1, other equipment mechanisms and connection methods are the same as Embodiment 1, and the coarse filter 7 is a stainless steel filter with a filtration precision of 200 mesh.

[0046] The coarse filter 7 can also be a polymer filter with a filtration precision of 150 mesh.

[0047] The filtering accuracy of the primary fine filter 8 is 50um, and the filtering area can also be 0.2m 2 .

[0048] The filtering accuracy of the primary fine filter 8 can also be 30um, and the filtering area can also be 0.1m 2 .

[0049] The filtering accuracy of the secondary fine filter 9 is 20um, and the filtering area can also be 0.01m 2 .

[0050] The filtering accuracy of the secondary fine filter 9 can also be 15um, and the filtering area can also be 0.2m 2 .

[0051] The membrane elements of the nanofiltration system 16 are disc membrane elements;

[0052] The membrane elements of the ultrafiltration system 12 are disc membrane elements.

[0053] The...

Embodiment 3

[0055] A method for concentrating and recovering effective components of a machining cleaning fluid by a system for concentrating and recovering active components of a machining cleaning fluid, comprising the following steps:

[0056] (1) Settling treatment: the waste liquid of the machining cleaning liquid flows into the settling tank 2 through the waste liquid inlet 1, and the solid matter in the waste liquid is settled by standing and settling, so that the solid matter in the waste liquid settles to the settling tank 2 At the bottom of the sedimentation tank 2, the solid matter is discharged through the sedimentation outlet 3 provided on the bottom of the sedimentation tank 2. The sedimentation outlet is opened every 12-24 hours, and the supernatant in the sedimentation tank 2 is pumped into the supernatant through the suction pump 4. In liquid tank 5, stand-by;

[0057] (2) Coarse filtration treatment: the supernatant liquid obtained in step 1) from the supernatant liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com