Multifunctional zipper checking machine and method for mounting zipper by applying multifunctional zipper checking machine

A multi-functional, inspection machine technology, applied in paper/cardboard containers, packaging, papermaking, etc., to achieve the effect of solving processing difficulties and speeding up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

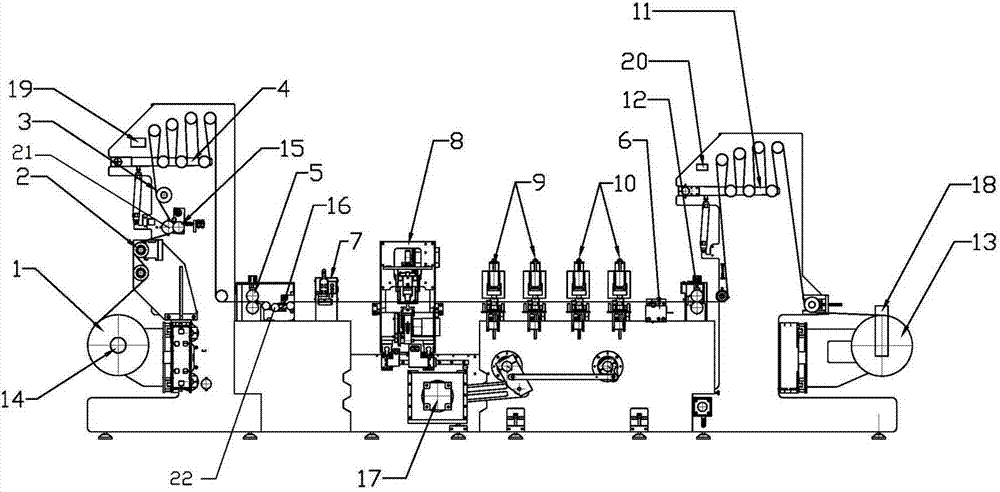

[0020] like figure 1 As shown, the multifunctional zipper inspection machine includes unwinding 1, pulling roller 21, A frequency conversion motor 15, pendulum roller 4, A conveying roller 5, dotted line punching device 7, horizontal zipper device 8, and heat sealing device 9 , cooling device 10, color code detection device 6, B conveying roller 12, swing roller 11, winding 13, B frequency conversion motor 18; A potentiometer 19 and B potentiometer 20 are set respectively above the swing roller 4 and the swing roller 11, The up and down swing amplitude data of the pendulum roller are respectively transmitted to the A frequency conversion motor 15 and the B frequency conversion motor 18 to control the speed of the unwinding 1 and the rewinding 13 respectively, and a dotted line punching device is arranged between the A conveying roller 5 and the B conveying roller 12 7. Horizontal zipper device 8 , heat sealing device 9 , cooling device 10 , and color code detection device 6 ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com