Method for testing rock composite fracture toughness based on asymmetric three-point bending loading of NDB sample

A three-point bending and composite fracture technology, which is used in the application of stable bending force to test the strength of materials and the preparation of samples for testing, etc. problems, to achieve the effect of solving the large error of the test results, low shape requirements, and avoiding the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

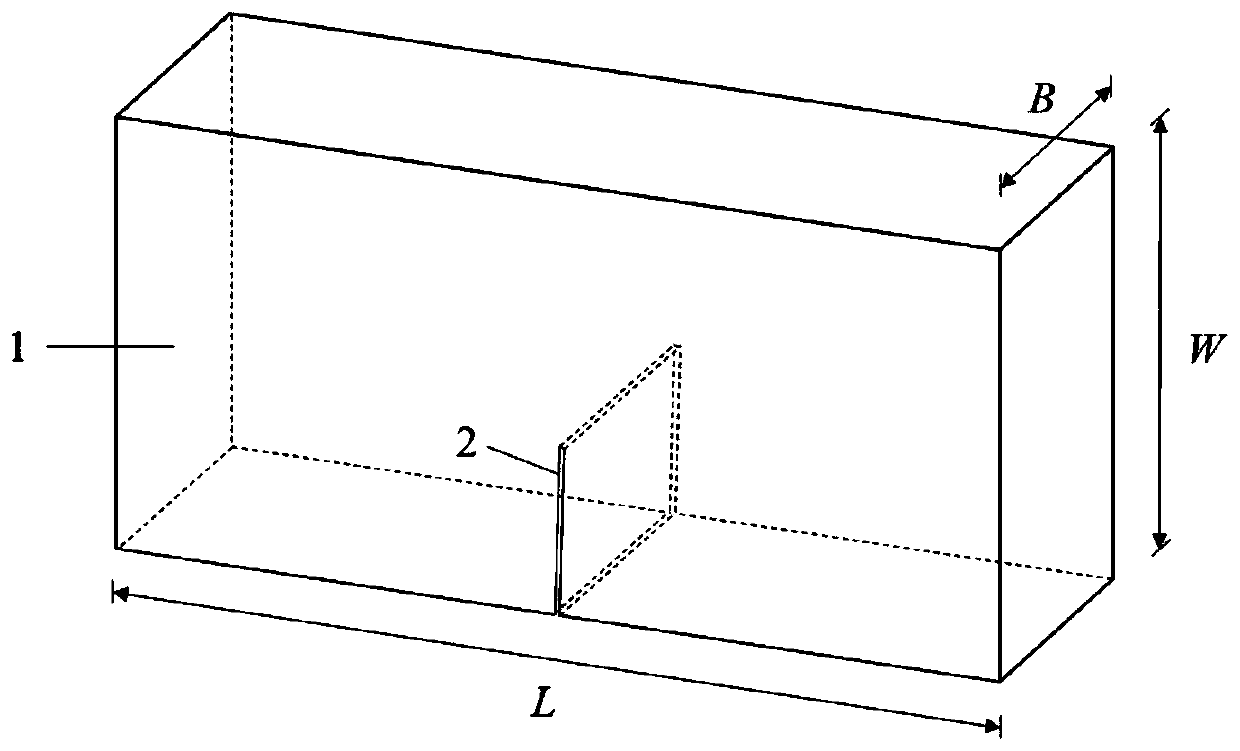

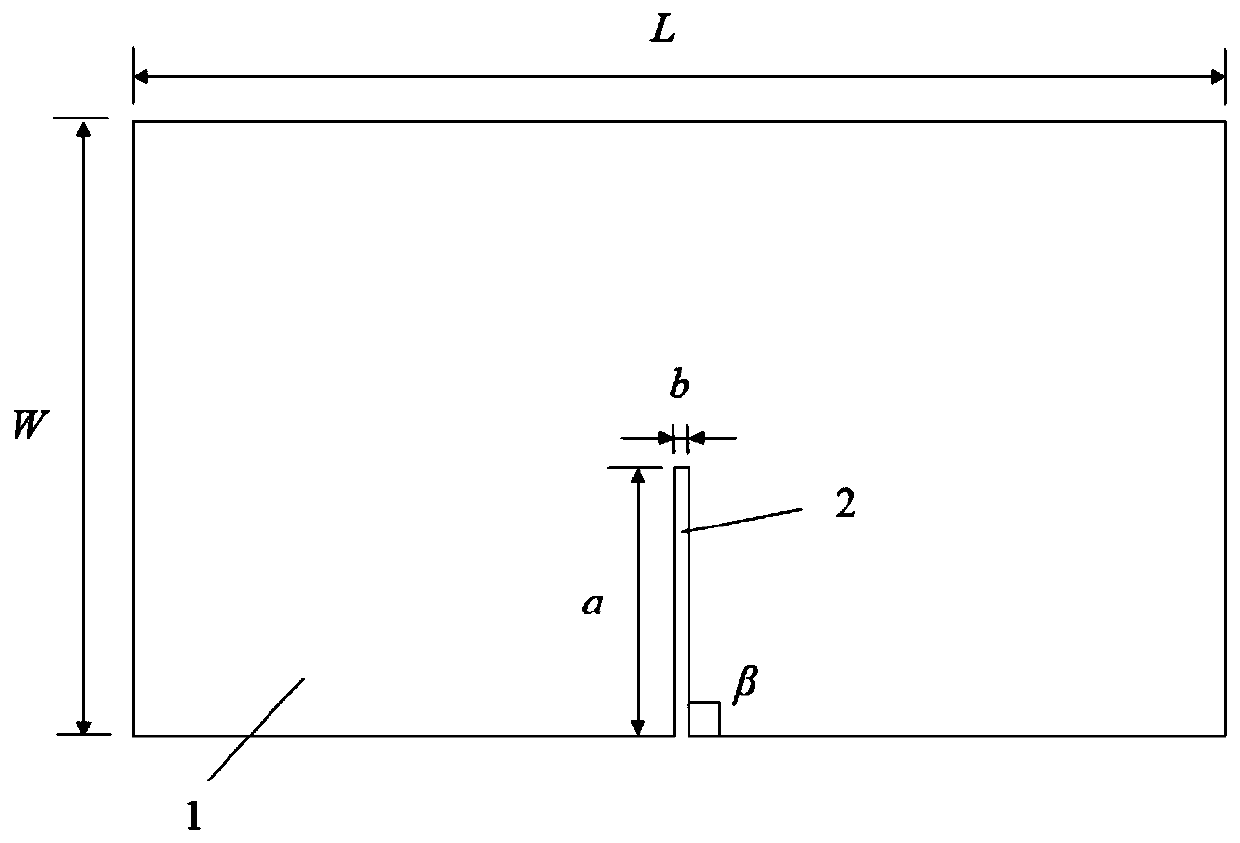

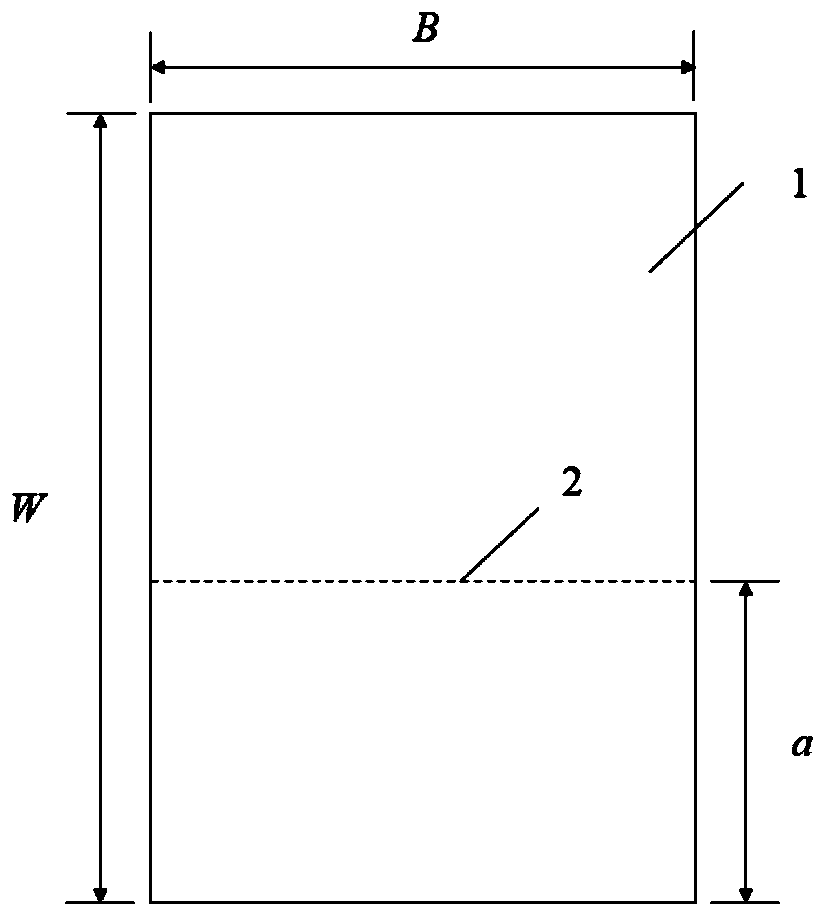

[0069] The deep beam specimen that is used for rock fracture toughness test described in this embodiment, see Figure 1~4 , the test material is sandstone, the test piece body 1 is a cuboid shape, and the body is provided with a centerline opening along the thickness B direction of the lower end surface of the body, extending to the inside of the body, and running through the front and rear end faces of the body thickness direction. The length L is 200mm, the width W is 100mm, and the thickness B is 80mm; the groove length a is 50mm (a / W ratio is 0.5), and the crack inclination β is 90°. The operation of rock fracture test with the above specimens is as follows:

[0070] 1) Adjust the distance S between the left support and the center line according to the scale of the three-point bending fixture 1 and the distance S between the right support and the center line 2 , such that S 1 60mm, S 2 is 6.5mm, and the difference between the front-end distance and the rear-end distanc...

Embodiment 2

[0078] The deep beam specimen that is used for rock fracture toughness test described in this embodiment, see Figure 1~4 , the test material is sandstone, the test piece body 1 is a cuboid shape, and the body is provided with a centerline opening along the thickness B direction of the lower end surface of the body, extending to the inside of the body, and running through the front and rear end faces of the body thickness direction. The length L is 200mm, the width W is 100mm, and the thickness B is 80mm; the groove length a is 50mm (a / W ratio is 0.5), and the crack inclination β is 90°. The operation of rock fracture test with the above specimens is as follows:

[0079] 1) Adjust the distance S between the left support and the center line according to the scale of the three-point bending fixture 1 and the distance S between the right support and the center line 2 , such that S 1 60mm, S 2 The distance between the front end and the rear end of the two supports after adjust...

Embodiment 3

[0088] The deep beam specimen that is used for rock fracture toughness test described in this embodiment, see Figure 1~4 , the test material is sandstone, the test piece body 1 is a cuboid shape, and the body is provided with a centerline opening along the thickness B direction of the lower end surface of the body, extending to the inside of the body, and running through the front and rear end faces of the body thickness direction. The length L is 200mm, the width W is 100mm, and the thickness B is 80mm; the groove length a is 50mm (a / W ratio is 0.5), and the crack inclination β is 90°. The operation of rock fracture test with the above specimens is as follows:

[0089] 1) Adjust the distance S between the left support and the center line according to the scale of the three-point bending fixture 1 and the distance S between the right support and the center line 2 , such that S 1 60mm, S 2 is 40mm, and the difference between the front-end distance and the rear-end distance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com