Terminal hole making actuator used for aircraft fuselage component lamination assembling

A technology for aircraft fuselage and actuators, which is applied in the field of terminal hole-making actuators, which can solve the problems of small tool adjustment and difficulty in processing large-diameter connecting holes, etc., so as to reduce the weight of the whole machine, avoid the difficulty of parts processing, and improve the position The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

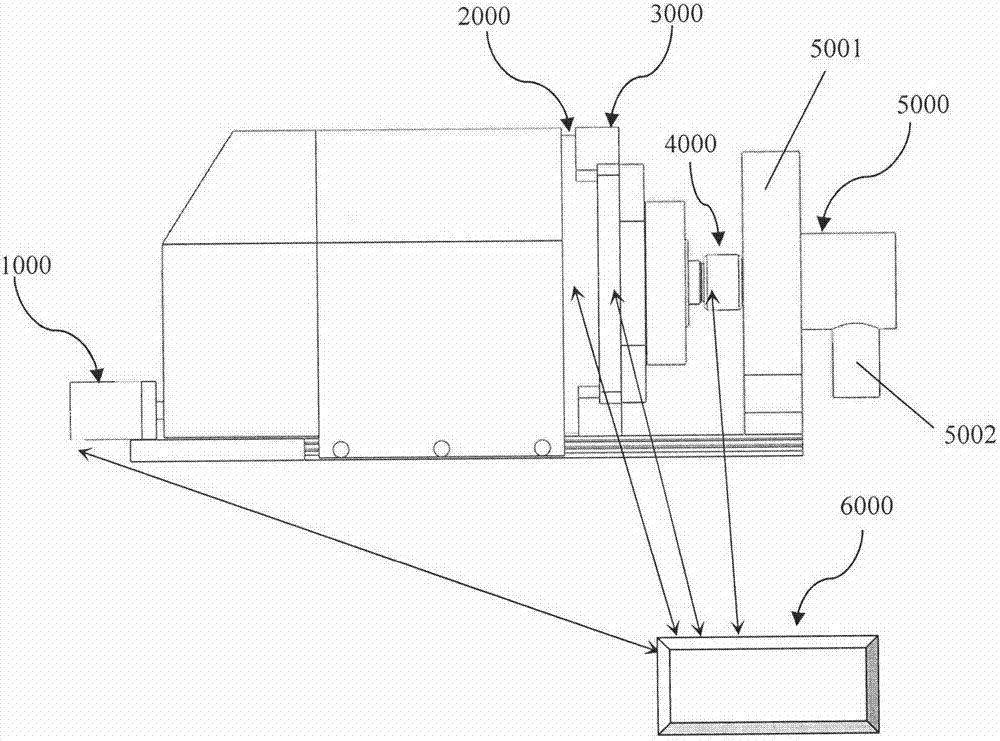

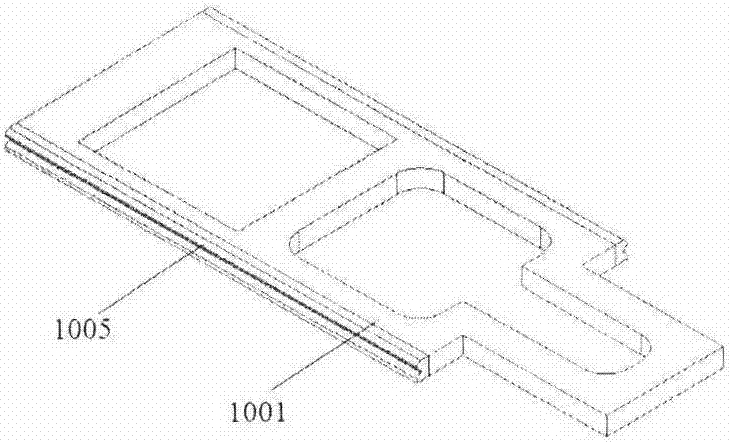

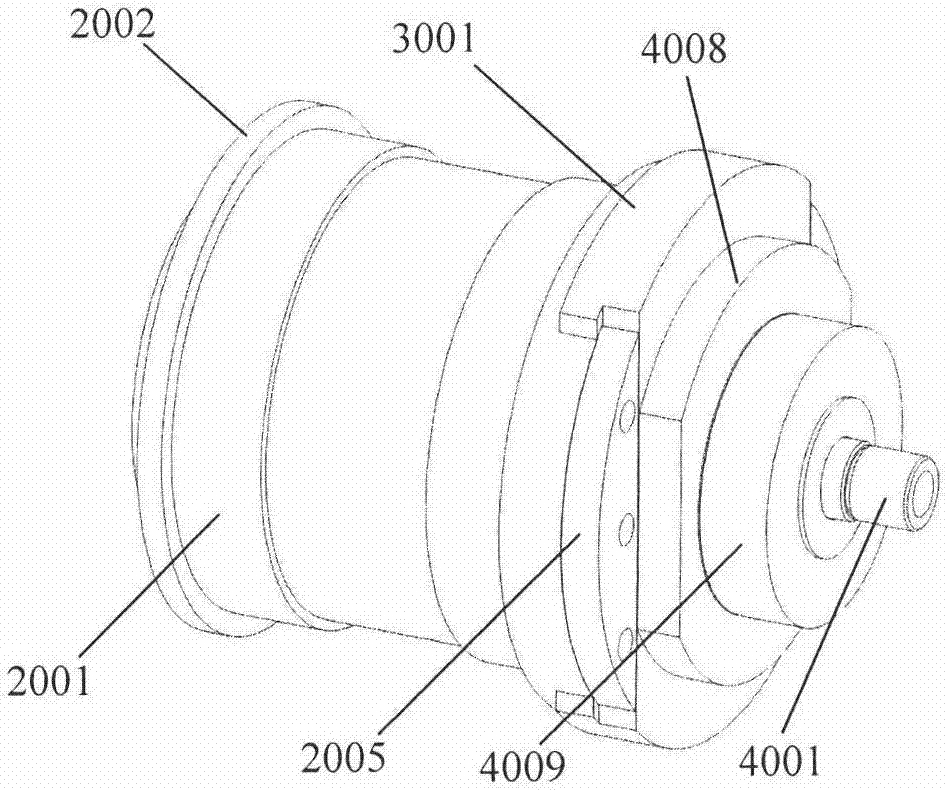

[0025] Such as Figure 1-5 As shown, the terminal hole-making actuator for laminated assembly of aircraft fuselage components of the present invention includes a convex supporting base plate 1001. The convex supporting base plate 1001 is provided with fixed guide rails 1005 on both sides of the large end and long sides, and also includes mounting The feeding mechanism 1000, the revolution mechanism 2000, the deviation adjustment mechanism 3000, the rotation mechanism 4000, the compacting chip removal mechanism 5000, and the system controller 6000 on the convex support base plate 1001. Among them, the system controller 6000 is electrically connected to the feeding mechanism 1000, revolution mechanism 2000, deviation adjustment mechanism 3000, and rotation mechanism 4000;

[0026] Wherein, the feed mechanism 1000 includes a sliding housing 1002, a sliding guide 1003, a feed nut 1009, a feed screw 1010, and a feed driving device 1011; the bottom of the sliding housing 1002 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com