Coarse stalk fuel gas purification process and purification device thereof

A technology of purification process and purification device, which is applied in the direction of combustible gas purification, combustible gas purification/transformation, gas dust removal, etc., which can solve the problems of non-compliance with energy saving requirements, increase of system failure rate, increase in the number of equipment, etc., and achieve long-term operation. , Excellent purification effect, and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

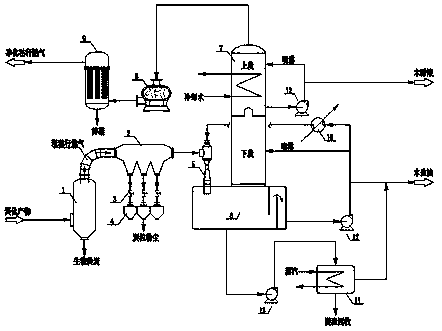

[0029] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0030] A kind of coarse straw gas purification process designed by the present invention comprises the following steps:

[0031] 1) Pre-treat the coarse straw gas to remove the large particle dust contained in it at one time;

[0032] 2), the gas treated in step 1) is passed into the lower part of the horizontal tube separator 7 for washing and dust removal, and the carbon dust and wood tar in the coarse straw gas are removed, and the water removal treatment is carried out, and the carbon dust and wood tar are collected In the sediment tank 6 at the lower end of the horizontal tube decondenser 7, the wood tar is separated and recovered, and the temperature of the lower section of the horizontal tube decondenser 7 is controlled at 75°C to 95°C;

[0033] 3), the gas treated in step 2) is passed into the upper section of the horizontal tube decond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com