Blockage removing device for wet desulphurization process

A wet desulfurization and process technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of unfavorable devices such as long-term operation, heavy workload, and slow flow rate of desulfurization liquid, and achieve good cleaning of the container wall. Effects of Brimstone's abilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

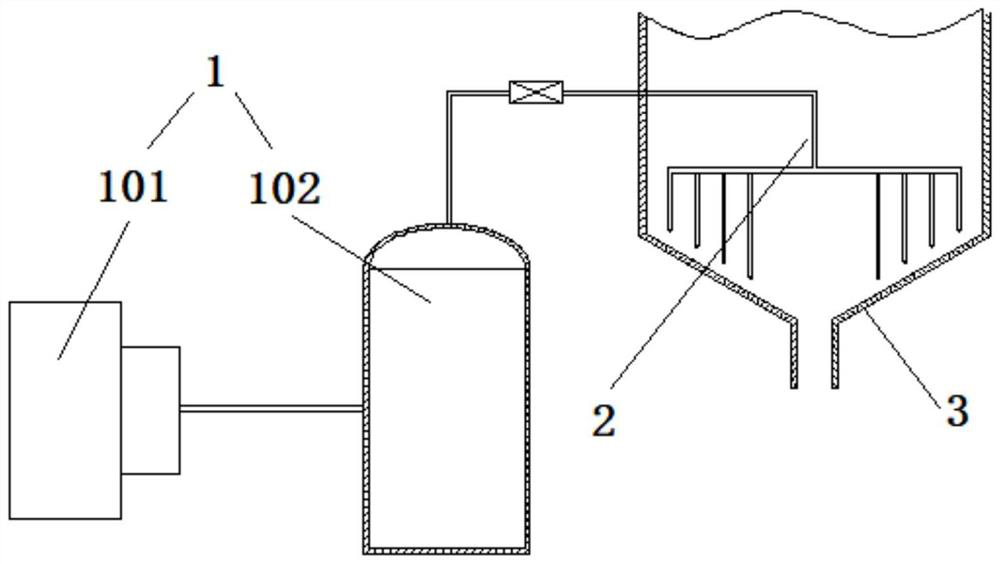

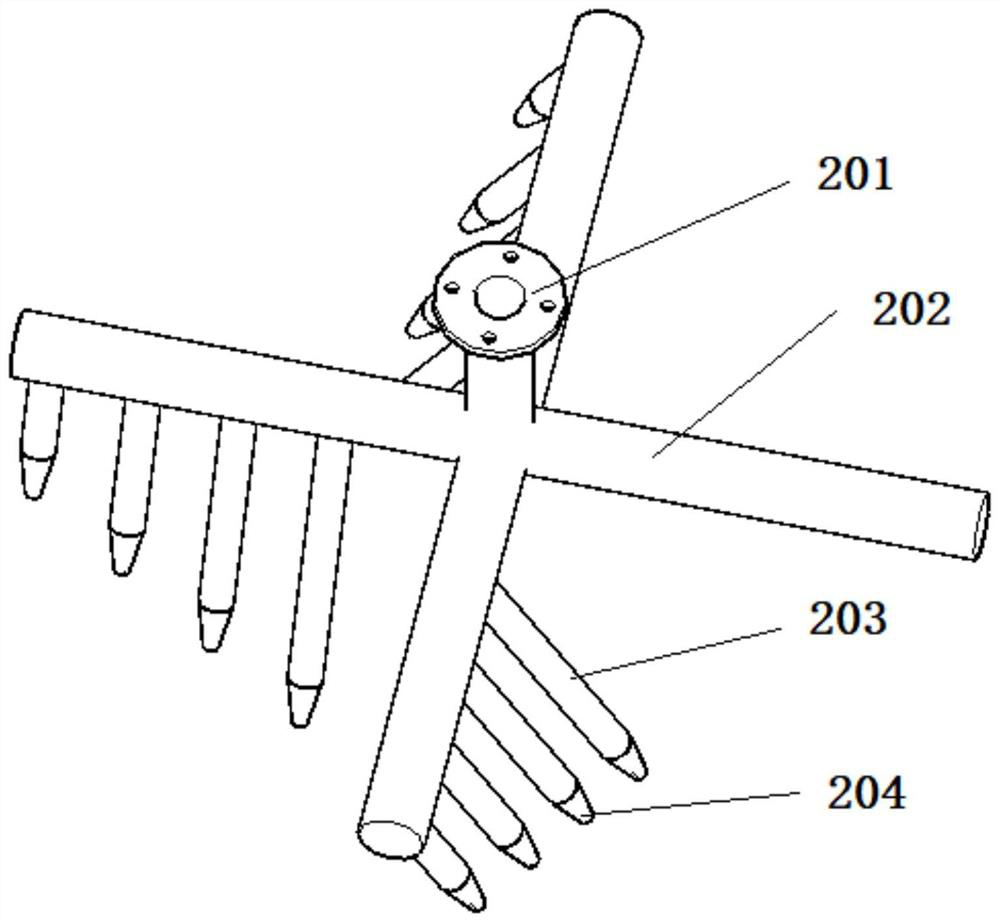

[0019]Please refer tofigure 1 withfigure 2,figure 1 Is a general schematic view of the present invention,figure 2It is a schematic structural diagram of the dispenser of the present invention. A wet desulfurization process uses a displaced device, including a gas source system 1 and a dispenser 2, a gas source system for intermittently supplying a compressed gas, a sulfur on the wall surface of the container 3, and a liquid.

[0020]The gas source system 1 includes a compressor 101 and a gas storage tank 102 sequentially connected, and the compressor is used to boost the gas, and the gas storage tank is used to store high-pressure gas for dispense use. A valve is provided on the gas outlet line on the top of the gas tank, preferably an electromagnetic valve or the like for quick opening, and off. After the valve is opened, the dispenser can supply compressed gas; the valve is turned off and the compressor can store the high pressure gas.

[0021]The dispenser 2 is located within the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com