Pyrolysis system for pyrolysis of broken coal, and device and method for producing semicoke, tar and coal gas by pyrolysis of broken coal

A pyrolysis gas and pyrolysis technology is applied in the field of pyrolysis systems for the pyrolysis of crushed coal, which can solve the problems of complex manufacture, low production efficiency, and difficulty in control of the double-sleeve rotary dryer, and is beneficial to long-term operation, Improve yield and quality, avoid the effect of tar condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

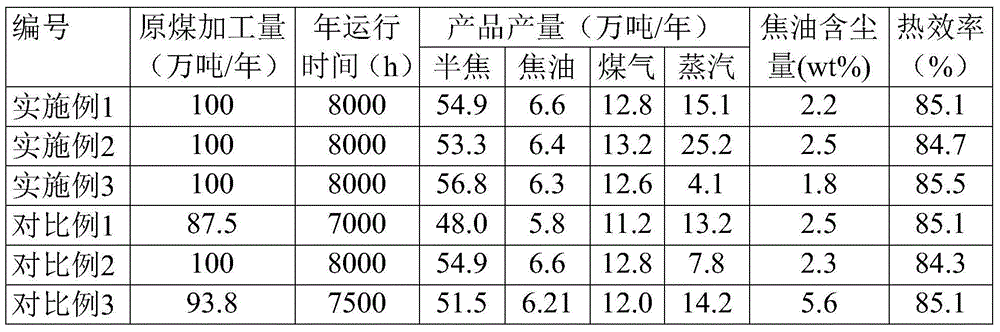

[0076] This example is used to illustrate the method for producing semi-coke, tar and gas by pyrolysis of pulverized coal of the present invention.

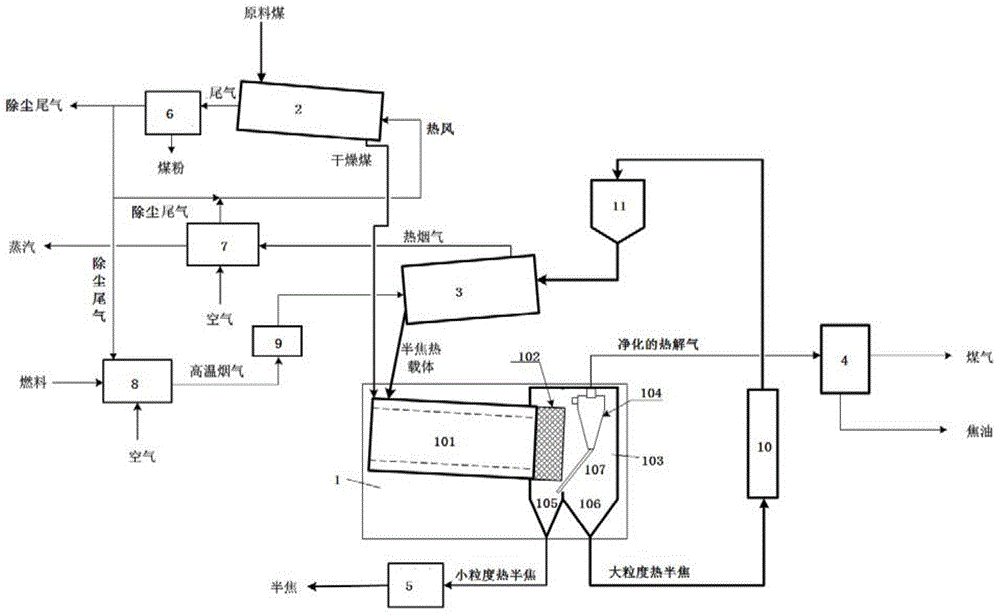

[0077] like figure 1 As shown, the discharge port of the rotary kiln pyrolyzer 101 is connected with a particle size classifier 102, and extends into the distribution bin 103 from the side of the distribution bin 103, and a cyclone separator 104 is set at the top of the distribution bin 103, and the A small hopper 105 and a large hopper 106 are provided below the silo 103 , and a discharge pipe 107 is connected to the particle outlet of the cyclone separator 104 and the small hopper 105 .

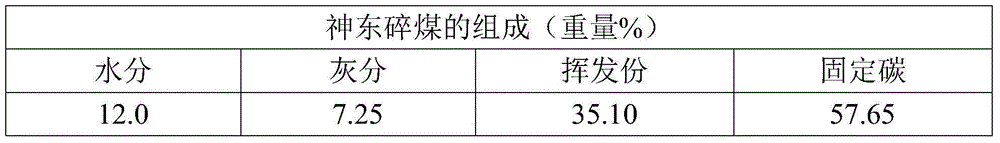

[0078] Dry coal by directly contacting the Shendong crushed coal rotary kiln dryer with hot air at 350°C in countercurrent; the feed rate of Shendong coal is 125t / h, and the air volume of hot air is 226240Nm 3 / h, the final temperature of coal drying is 200°C, and the water content of dry coal is 2.6%; the temperature of the tail gas discharg...

Embodiment 2

[0093] This example is used to illustrate the method for producing semi-coke, tar and gas by pyrolysis of pulverized coal of the present invention.

[0094] like figure 1 As shown, the discharge port of the rotary kiln pyrolyzer 101 is connected with a particle size classifier 102, and extends into the distribution bin 103 from the side of the distribution bin 103, and a cyclone separator 104 is set at the top of the distribution bin 103, and the A small hopper 105 and a large hopper 106 are provided below the silo 103 , and a discharge pipe 107 is connected to the particle outlet of the cyclone separator 104 and the small hopper 105 .

[0095] Dry coal by directly contacting the Shendong crushed coal rotary kiln dryer with 300°C hot air countercurrent; the feed rate of Shendong coal is 125t / h, and the air volume of hot air is 260680Nm 3 / h, the final temperature of coal drying is 150°C, and the water content of dry coal is 3.6%; the temperature of the tail gas discharged fro...

Embodiment 3

[0102] This example is used to illustrate the method for producing semi-coke, tar and gas by pyrolysis of pulverized coal of the present invention.

[0103] like figure 1 As shown, the discharge port of the rotary kiln pyrolyzer 101 is connected with a particle size classifier 102, and extends into the distribution bin 103 from the side of the distribution bin 103, and a cyclone separator 104 is set at the top of the distribution bin 103, and the A small hopper 105 and a large hopper 106 are provided below the silo 103 , and a discharge pipe 107 is connected to the particle outlet of the cyclone separator 104 and the small hopper 105 .

[0104] The dry coal is obtained by directly contacting the Shendong crushed coal rotary kiln dryer with hot air at 400°C in countercurrent; the feed rate of Shendong coal is 125t / h, the air volume of hot air is 205240Nm3 / h, and the final temperature of coal drying is 250 ℃, the water content of the dried coal is 1.1%; the temperature of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com