Dry desulfurization dust removing technology method for catalytic cracking regenerated flue gas

A technology for catalytic cracking and regenerating flue gas, applied in chemical instruments and methods, chemical elements of heterogeneous catalysts, separation methods, etc., can solve problems such as falling rain, low SOx removal rate from flue gas, freezing and salty wastewater, etc. , to achieve the effect of good effect, high flue gas purification efficiency and dust emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment provides a method for preparing a desulfurization catalyst, which specifically includes the following steps:

[0057] Step one, aluminum magnesium spinel (MgAl 2 o 4 ) preparation:

[0058] Add 5000g of H in a 10-liter three-neck flask 2 O, 228g of NaOH and 89g of Na 2 CO 3 , Stir well at 65°C, add 3000g of H 2 O, 221g of Mg(NO 3 ) 2 ·6H 2 O, 187g of Al(NO 3 ) 3 9H 2 The dropwise addition time of the O solution is 0.6h. After the dropwise addition, continue to stir for nucleation and crystallization for 18h, then cool, filter with suction, wash until neutral and dry to obtain magnesium aluminum spinel.

[0059] Step 2, preparation of manganese magnesium aluminum hydrotalcite (MnMgAl-LDH):

[0060] Add 5000g of H in a 10-liter three-neck flask 2 O, 252g of NaOH and 53g of Na 2 CO 3 , Stir well at 75°C, add 3000g of H 2 O, 9.5g of Mn(NO 3 ) 2 4H 2 O, 524g of Mg(NO 3 ) 2 ·6H 2 O, 247g of Al(NO 3 ) 3 9H 2 O solution, the dropwise add...

Embodiment 2

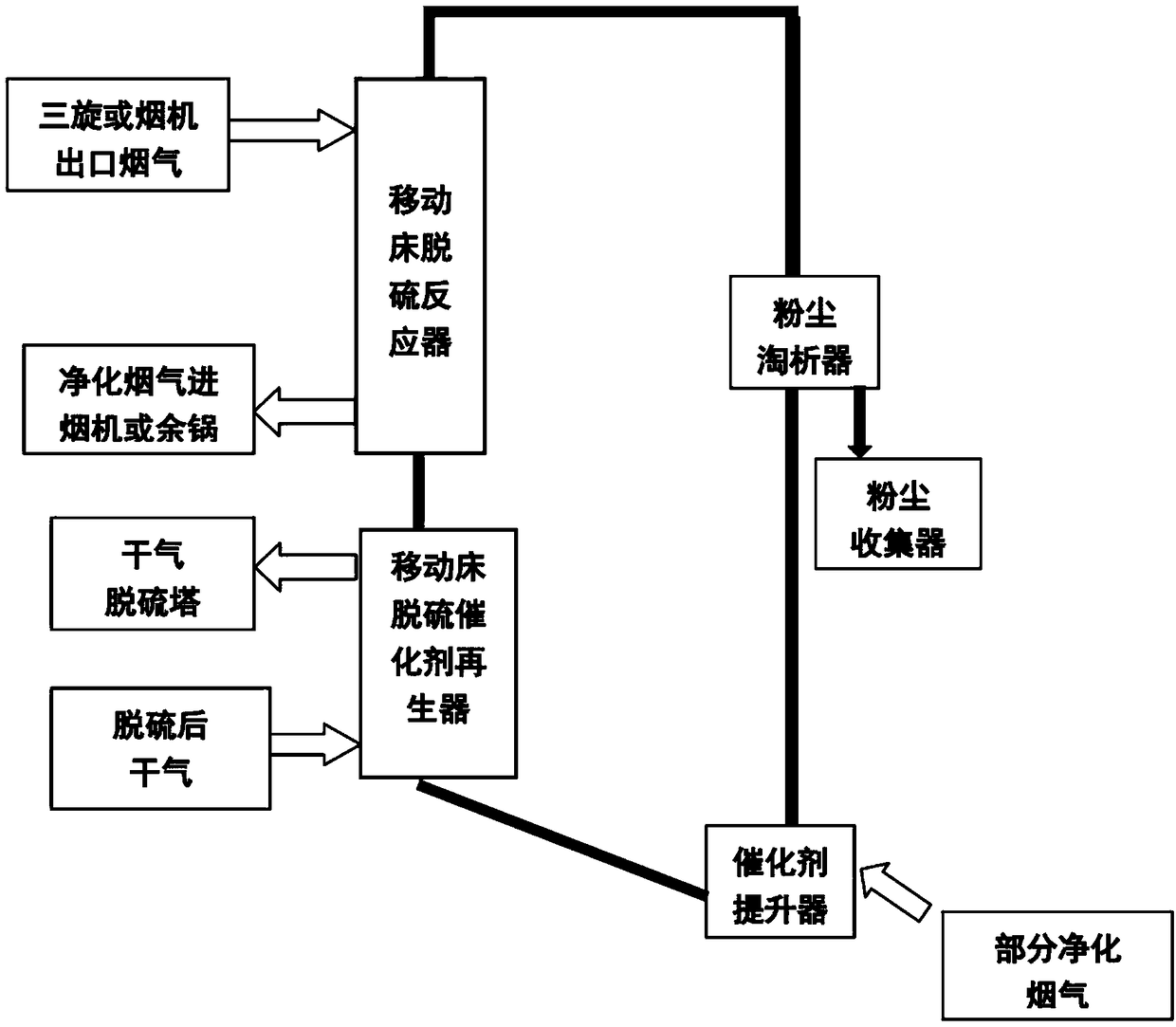

[0064] This embodiment provides a dry desulfurization and dust removal process for catalytic cracking regenerated flue gas, such as figure 1 as shown, figure 1 It is a schematic flow chart of the desulfurization and dust removal process in this embodiment, and the dust removal process specifically includes the following steps:

[0065] Step 1, the catalytic cracking flue gas is passed into the moving bed desulfurization reactor, and the desulfurization reaction is carried out with the desulfurization catalyst prepared in Example 1 loaded in the moving bed desulfurization reactor, and the sulfur oxide in the flue gas is catalytically reacted to generate metal sulfuric acid Salt, and adsorbed on the desulfurization catalyst, while the desulfurization catalyst further intercepts the dust in the flue gas, and the desulfurized and purified flue gas is returned to the smoke machine or the waste pot.

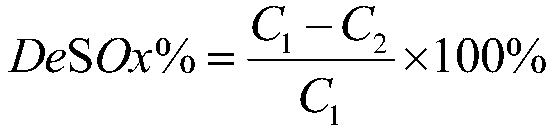

[0066] The reaction of the following formula (1) is carried out in the moving bed...

Embodiment 3

[0073] This embodiment is the laboratory simplified simulation experiment of embodiment 2, a kind of catalytic cracking regenerated flue gas dry desulfurization dedusting process method, adopts micro-quartz reactor simulation moving bed desulfurization reactor; Take simulated flue gas (by SO 2 and 3.5v%O 2 , 96.5v% N 2 The mixed gas) simulates the catalytic cracking flue gas. The specific operation is as follows:

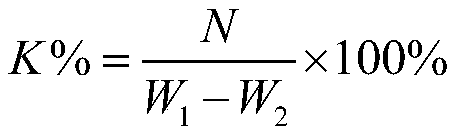

[0074] Weigh 1.0g of the desulfurization catalyst prepared in Example 1 and put it into a Φ8×1mm quartz tube reactor, heat the catalyst to a certain temperature while feeding nitrogen, then stop the nitrogen, and feed the 2 The mixed gas was collected for 60 minutes, and the gas was collected and analyzed for SO 2 Concentration, this process is the reaction stage. After the reaction, stop the SO 2 Mixed gas, purging with nitrogen for 10 minutes, passing regeneration gas (including one or more of hydrogen, carbon monoxide or methane, etc.) at a certain temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com