Mixed hydrogenation method for catalytic cracking gasoline and coking diesel oil

A technology for catalytically cracking gasoline and coking diesel, which is applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., to avoid coking, reduce octane number loss, and have a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

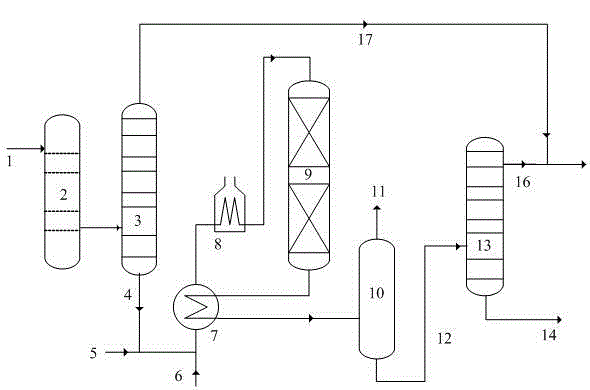

[0027] Embodiment 1~3 adopts figure 1 The process flow shown.

[0028] The catalyst used for alkali-free deodorization of FCC gasoline is the AFS-12 prefabricated catalyst developed by China University of Petroleum. The same process conditions are used for alkali-free deodorization: reaction pressure 0.6MPa, reaction temperature 40°C, feed space velocity 0.9h -1, the air flow / feed volume ratio is 0.7.

[0029] After alkali-free deodorization, FCC gasoline is fractionated in the hydrogenation pre-fractionator, and the cutting temperature of light gasoline and heavy gasoline is 50°C. Heavy gasoline is mixed with coked diesel oil and hydrogen and enters the hydrorefining reactor for reaction. After the hydrorefining products are separated and fractionated, refined heavy gasoline and light gasoline are blended to obtain gasoline products.

[0030] The hydrodesulfurization catalyst is selected from the FGH-21 / FGH-31 combination catalyst developed by Fushun Petrochemical Researc...

Embodiment 1~3

[0033] Table 2 Hydrodesulfurization Process Conditions of Examples 1-3

[0034] Example 1 Example 2 Example 3 Raw oil FCC heavy gasoline / coking diesel 1=2 FCC heavy gasoline / coking diesel 2=3 FCC heavy gasoline / coking diesel 3=4 Feed nitrogen content, μg / g 425 473 436 Reaction temperature, °C 260 280 300 Reaction pressure, MPa 1.6 1.6 1.6 volumetric space velocity, h -1 3.0 3.0 2.5 Hydrogen oil volume ratio 300 300 300

[0035] Table 3 Properties of blended gasoline products obtained in Examples 1-3

[0036] Example 1 Example 2 Example 3 Density(20℃) / g·cm -3 0.7314 0.7312 0.7268 Distillation range (ASTM D 86), °C initial boiling point 35 35 35 10% 55 56 54 50% 98 97 98 90% 170 169 170 end point 191 190 189 Sulfur, μg / g 132 27 8 RON 94.1 93.8 92.8 RON loss 0.4 0.7 1.7 Stable operation period, h 8000 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com