Method and device for purifying dry feed gas for preparing ethyl benzene

A purification device and dry gas technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of frequent replacement of adsorbents, poor removal, and short service life of deamination adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

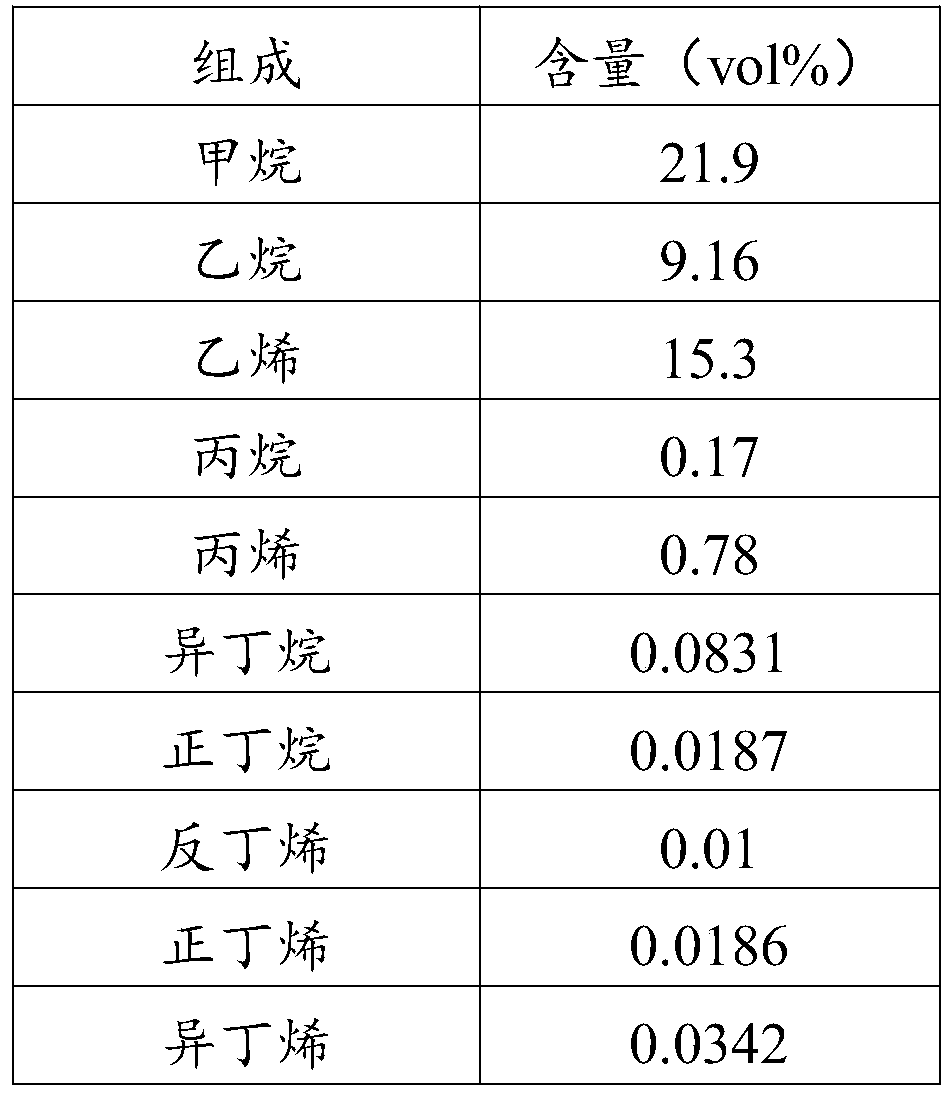

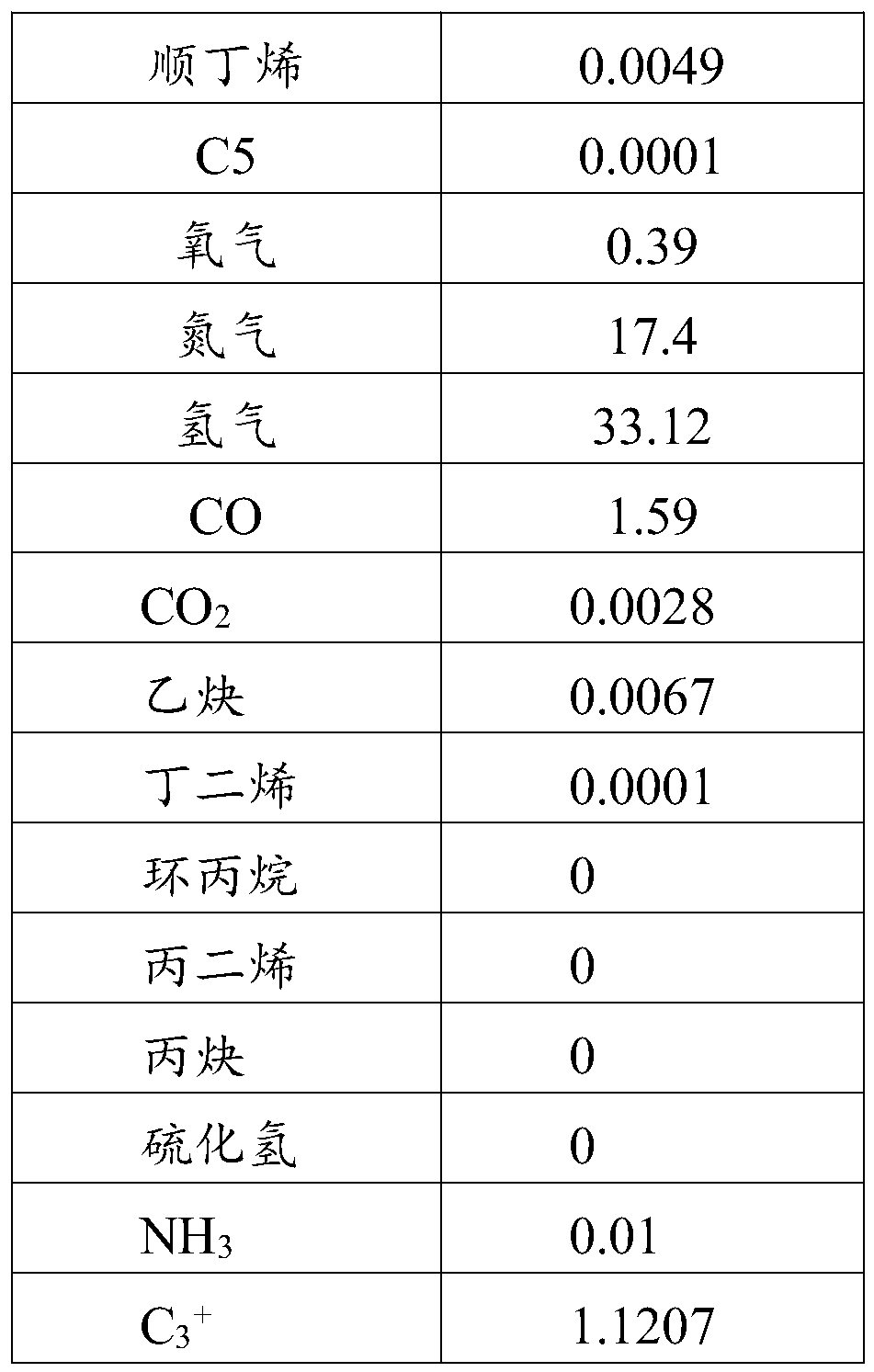

[0110] The specific composition and content of raw material dry gas are shown in Table 1.

[0111] Table 1 Concrete composition and content of raw material dry gas

[0112]

[0113]

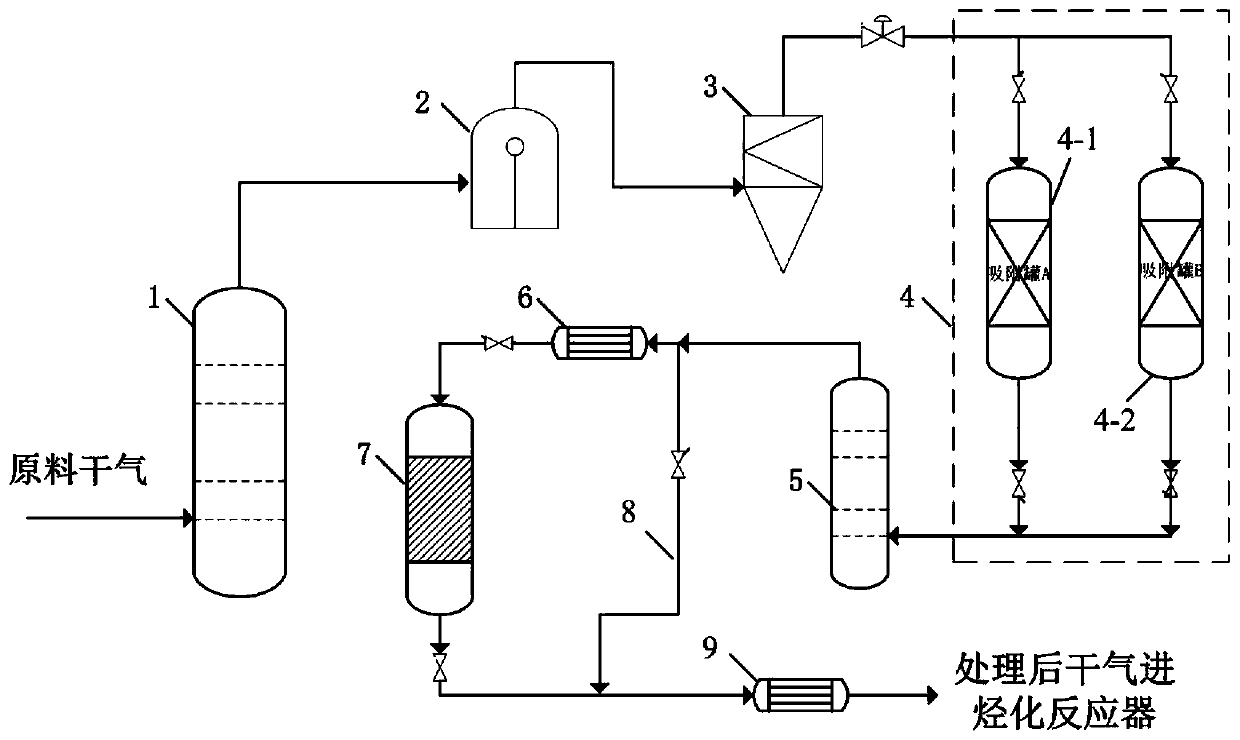

[0114] use figure 1 The purification device for the raw material dry gas shown for the production of ethylbenzene includes:

[0115] washing tower;

[0116] A gas inlet is connected to a cyclone separator connected to the gas outlet of the water washing tower;

[0117] a coalescer having a gas inlet connected to the gas outlet of said cyclone;

[0118] The first adsorption tower whose gas inlet is connected to the gas outlet of the coalescer (open the control valve on the inlet pipeline and the gas outlet pipeline of the first adsorption tower, close the control valve on the inlet pipeline and the gas outlet pipeline of the second adsorption tower) valve, close the control valve on the cross-line pipeline);

[0119] A propylene absorption tower whose gas inlet is connected to the gas o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com