Hydrogenation method of high-chlorine C9 petroleum resin

A petroleum resin and resin technology, applied in the field of hydrogenation of high-chlorine C9 petroleum resin, can solve the problems of complicated process, increased energy consumption, poor removal effect, etc., and achieve the effect of high removal accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

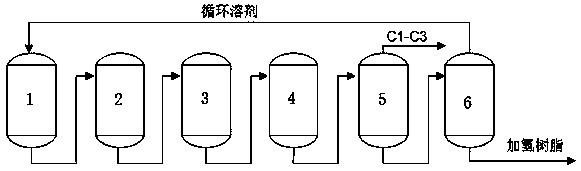

[0022] Below in conjunction with accompanying drawing and specific example the present invention will be further described:

[0023] The technological process that the present invention adopts is figure 1 The technological process in, concrete technological process is as follows:

[0024]Dissolve C9 petroleum resin with a solvent in the resin dissolving tank 1, and the petroleum resin accounts for 10-30% by mass, then mix it with hydrogen, enter the first stage hydrogenation reactor 2 after heating, and carry out hydrogenation adsorption dechlorination removal Chlorine in resin, reaction temperature 150-200°C, pressure 8-17MPa, volume space velocity 1-3h -1 , the volume ratio of hydrogen to oil is 50-200, and the catalyst used is NiCu / Al 2 o 3 -SiO 2 -MgO;

[0025] The first-stage hydrogenation product enters the second-stage hydrogenation reactor 3, and undergoes hydrogenation adsorption desulfurization to remove sulfur in the resin. The reaction temperature is 220-300°C...

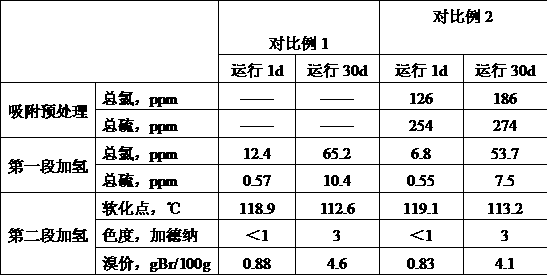

Embodiment 1

[0029] C9 resin is dissolved in cyclohexane, the mass ratio of the resin is 20%, the first hydrogenation reaction temperature is 150°C, the pressure is 17MPa, and the volume space velocity is 1h -1 , the volume ratio of hydrogen to oil is 50, and the catalyst used is NiCu / Al 2 o 3 -SiO 2 -MgO, Al used 2 o 3 -SiO 2 -MgO carrier, SiO by mass percent 2 The content is 7%, the MgO content is 9%, and the rest is Al 2 o 3 , the content of active components of the catalyst is based on the total mass of the catalyst. The content of NiO in the active components is 11%, and the content of CuO is 20%. -1 , the volume ratio of hydrogen to oil is 300, and the catalyst is NiZn / Al 2 o 3 , based on the total mass of the catalyst, the content of NiO is 25%, the content of ZnO is 20%, and the rest is Al 2 o 3 ; The temperature of the third hydrogenation reaction is 230°C, the pressure is 17MPa, and the volume space velocity is 0.5h -1 , the volume ratio of hydrogen to oil is 400, and...

Embodiment 2

[0031] C9 resin is dissolved in n-heptane, the mass ratio of the resin is 10%, the first hydrogenation reaction temperature is 200°C, the pressure is 8MPa, and the volume space velocity is 3h -1 , the volume ratio of hydrogen to oil is 130, and the catalyst used is NiCu / Al 2 o 3 -SiO 2 -MgO, Al used 2 o 3 -SiO 2 -MgO carrier, SiO by mass percent 2 The content is 10%, the MgO content is 13%, and the rest is Al 2 o 3 , the content of active components of the catalyst is based on the total mass of the catalyst. The content of NiO in the active components is 15%, and the content of CuO is 16%. -1 , the volume ratio of hydrogen to oil is 450, and the catalyst is NiZn / Al 2 o 3 , based on the total mass of the catalyst, the content of NiO is 35%, the content of ZnO is 10%, and the rest is Al 2 o 3 ; The temperature of the third stage hydrogenation reaction is 320°C, the pressure is 8MPa, and the volume space velocity is 1h -1 , the volume ratio of hydrogen to oil is 800, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com